Как выбрать гостиницу для кошек

14 декабря, 2021

Jesfis Lopez-Villada*, Joan Carles Bruno, Alberto Coronas

Universitat Rovira i Virgili, CREVER — Group of Applied Thermal Engineering, Mechanical Engineering Department, Avda. Paїsos Catalans, 26, 43007-Tarragona, Spain Corresponding Author, iesus. lopez@urv. cat

Abstract

In this paper different solar cooling thermal plant design alternatives are analysed for their integration into a District Heating and Cooling (DHC) network based on a trigeneration plant using natural gas reciprocating engines. This facility is planned to be located in Cerdanyola del Valles (Barcelona) in the framework of the Polycity project (Concerto Programme) [1].

The purpose of the solar plant is to provide cooling to the DHC network users in order to reduce the primary energy consumption and the environmental impact caused by the energy generation system.

The solar cooling plant design alternatives are modelled in TRNSYS considering different types of solar thermal collectors and thermal chillers. For the modelling of the thermal chillers a new mathematical approach has been developed and implemented in the TRNSYS simulation platform. This approach is based on a modified characteristic equation method presented by Ktihn and Ziegler [2]. With this method a mathematical correlation of available catalogue data of different manufacturers is generated for each absorption and adsorption chiller.

Finally, in order to select the best option from an energy and economic point of view, the energy results and costs of the different alternatives are estimated and compared with the results of a previous study.

Keywords: Solar cooling, adsorption chiller, absorption chiller, TRNSYS

The POLYCITY project, funded by the EU-programme Concerto, focuses on large scale urban developments where living and working areas are integrated to result in sustainable city quarters [1]. The Catalonian project focuses on a large urban development in the community of Cerdanyola del Valles close to Barcelona. Almost two million square meters of buildings will be constructed within the next decade. Industrial and services buildings will be supplied with a very innovative energy system including a district heating and cooling network that is foreseen to integrate different subsystems. One of these is a large scale solar thermal cooling plant, the design, performance and economics of which are analysed in the present study.

The main objective of this analysis is to decide which is the best solar collector-thermal chiller combination for the large scale solar plant. In order to improve the results of this analysis compared to a previous study [3], a more accurate mathematical model of the thermal chillers is used. In addition, due to the economic analysis is very sensitive to the specific costs of the thermal chillers, we considered more real values of these coefficients according to the information found in the references [5] [6] [7].

In this work, the well-known transient simulation program TRNSYS [4] is used. Three types of solar thermal collectors and a total of four types of sorption chillers of different technologies (absorption and adsorption) and different chilling capacities are considered. It should be remarked that to perform this analysis we developed and implemented in the TRNSYS platform a new model (type 811) for both the adsorption and absorption thermal chillers. This model is based on the modified characteristic equation method presented by Ktihn and Ziegler [2]. With this method a mathematical correlation of available catalogue data of different manufacturers is generated for each adsorption and absorption chiller.

Regarding to the economic analysis, this is performed considering the total initial investment cost necessary to produce 700 MWh of chilled water.

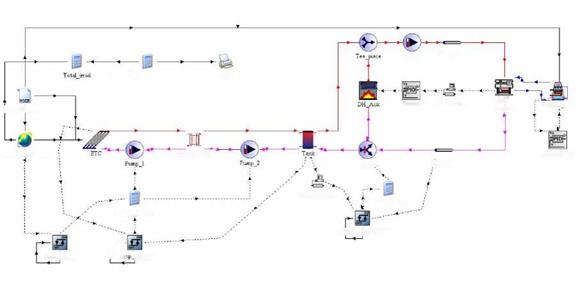

Fig. 1 shows the model developed in the TRNSYS environment for one of the options analysed. The main components of this model are the meteorological data file, the solar thermal collector system, the sorption chiller, the cooling tower, the buffer tank and the control system.

Three solar collector types are analysed in this study: Flat Plate Collector (FPC) (Sonnenkraft SK — 500), Evacuated Tube Collector (ETC) (Thermomax Memotron TMO 600) and Compound Parabolic Collector with Evacuated Tube Collector (ETC-CPC) (Sydney SK-6). The collectors are considered facing true South (azimuth = 0°) with a tilt angle of 35°, in order to obtain the maximum solar energy yield.

ON_OFF_3way_valve

ON_OFF_3way_valve

Figure 1. Basic TRNSYS’s diagram of the model for the solar cooling system with ETC collectors and an

ad/absorption chiller.

We selected as absorption chillers the single-stage hot water chillers BROAD BDH-50 and BDH-65 with a chilling capacity of 512 and 768 kWc respectively. For the adsorption option we selected a group of two MYCOM ADR-80 with a total capacity of 560 kWc and another of two ADR-60 with 422 kWc. In all the simulated cases the chillers operate with a temperature gap of the chilled water of 12°C / 7°C, the volume of the buffer tank was set to 10 m3 and the cooling tower modelled was the closed type Baltimore FXV-364-31N.

The control consists of the elements detailed below:

• A controller of solar radiation.

• A temperature differential controller between the solar collector field and the buffer tank.

• A temperature differential controller between the buffer tank and the outlet temperature of the generator of the chiller.

• A PID controller for the chilled water outlet temperature adjusted to 7°C which operates increasing or decreasing the auxiliary heat provided by the DH network.

• A PID cooling tower control adjusted to maintain the outlet cooling water temperature as low as possible with a minimum of 22°C.

The energy performance of the solar system varying the collectors surface and the storage tank volume was evaluated. The collectors used for the simulation are already in existence and heat a water-glycol mix in order to reach temperatures of up to 120 °C.

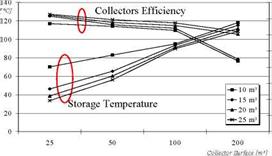

The capturing surface was made to vary between 25 m2 and 200 m2 and the storage volumes from 10 m3 to 25 m3. These values result as being large for the inlet temperatures of the radiant ceiling during winter, but are necessary in order to guarantee regular functioning of the absorption machine during summer. In Figure 3 the average seasonal temperature trend of the tank and the average seasonal yield of the collectors varying the capturing surface and storage volume is represented. High temperature within the tank penalises the performance of the collectors. Furthermore, given that the required inlet temperatures of radiant ceilings are 30^40 °C, the mixing system (1) operates for part of the time with high recirculating flow rates and low flow rates taken from the tank. The rapid decrease of the efficiency of the collectors which is recorded for an capturing surface area of 200 m2 and for a storage volume of 10 m3 and 15 m3 is linked to the

reaching of the maximum temperature and the operation of the safety valve of the primary circuit of Figure 1 which interrupts the accumulation of thermal energy in the tank. The reaching of high temperatures gives rise above all to limited global yields of the solar system which do not vary with the volume of the storage tank.

In Figure 4 the trend of the energy captured by the solar collectors , of the energy provided by the auxiliary system and of the energy extracted from the storage tank, varying the collectors surface and storage volume is shown. The seasonal thermal energy provided by the auxiliary system and the energy extracted from the tank are practically constant with the storage volume, and their sum represents the seasonal requirement of thermal energy of the building which appears to be equal to around 35000 kWh. From Figure 4 it is possible to observe the minor energy captured by the solar collectors upon reaching the maximum temperature in the tank.

![]() 80000 70000 ^ 60000 50000 40000 30000 20000 10000 0

80000 70000 ^ 60000 50000 40000 30000 20000 10000 0

0 50 100 150 200 250

Collectors Surface [m2]

Fig. 4. Seasonal energy captured by the collectors, energy provided by the auxiliary system and energy extracted from the storage tank varying the capturing surface and storage volume

|

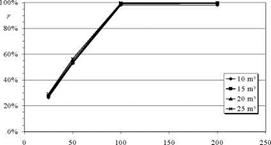

The requirement energy fraction obtained from the solar source, represented in Figure 5, assumes values that vary from 26% until almost 100%; a rapid increase is highlighted moving from an capturing surface of 25 m2 to an capturing surface of 100 m2, while it remains almost constant with the storage volume and for capturing surfaces greater than 100 m2.

Collectors Surface [m2]

Fig. 5. Solar fraction trend varying the capturing surface and storage volume

The last step of the method consists in presenting the different results of the method in a synthetic table. Beside, this step will give the opportunity from the analysis of the results to make some retrofit according to scheme presented in Figure 4.

Fig. 4. Organisation of the different steps inside the method.

3. Conclusion

The fast predesign method presented in this poster is coming from a state of the art and a general request coming from the solar cooling field : some accurate and performing tools are already existing (methods to pre-select the technology and the hydraulic scheme according the building and the meteorology and best practice to pre-design the main component of the system) but, one single and synthetic tool is missing gathering all the work already done, friendly and easy-to-play and Internet available. This theoretical method should permit to reach this goal. Unfortunately, it is not yet applied due to the lack of budget among the different participants to the IEA Task 38 Subtask B4. The objectives in the future are the following : develop the tool by improving some applications and finding the budget to develop the tool, test the tool among beta testers and commercialize the tool

References

[1] Task 38, Solar Air-Conditioning and Refrigeration, located in the Heating & Cooling (SHC) Programme of the International Energy Agency IEA. www. iea-shc-task38.org

[2] H. M Henning, (2004). IEA Task 25 Guideline document

[3] T. Nunez, H. M Henning,(2007), PolySMART© Load generator Guidelines

[4] Hans-Martin Henning, (2003), SACE. Solar Cooling Light Computer Tool — Guidelines for Use, Fraunhofer Institute for Solar Energy Systems ISE, , EU Contract NNE5-2001-00025

[5] L. Siso, (2007), ROCOCO (Reduction of Cost for solar cooling systems), EU contract TREN/05/FP6EN/S07.54855/020094

During the work in IEA Task 25 also a Type 107 has been developed for TRNSYS-15 [5]. The source code has now been updated to TRNSYS-16. To avoid conflicts the Type number has been changed to 177. The Type uses the method of characteristic equations [4], which can be used to describe the part load behaviour of ad — and absorption chillers. For application of this method to single stage absorption chillers the four mean external temperatures at the heat exchangers (Generator, Absorber, Condenser, Evaporator) are combined in one parameter (ДД) using the Duhring coefficient B to take the applied working pair into account. For common operating conditions of H2O/LiBr chillers B can be set constant in a range of 1.1 to 1.2.

ДД ttG — tA —{tc — t E )•B (3)

With the characteristic temperature difference (ДД0 the cooling capacity QE can be described as a linear function, if the variation of all heat transfer coefficients (which are combined in the slope sE) is negligible and if the imperfection of the internal heat recovery as well as additional losses (which are both described by rE) are constant or proportional to the load (or ДД, respectively).

Qe — Se •ДДt + Ге (4)

Commonly these assumptions of linearity are fulfilled in a wide part load range and the capacity of an absorption chiller can be characterised by (4) with an accuracy of ~10%. A linear part load behaviour is also to be expected, when a modified characteristic temperature difference ДДї* is used, where the more often available inlet and outlet temperatures are used.

ДД t*:— ta — (1 + B)• tAC + B • tE (5)

In addition, the accuracy can be improved [6], if the characteristic parameters are not set constant but are allowed to vary as function of the external temperature lift (AtACE = tAC — tE).

QX — SX (^ACE )^ДД t + rx (^ACE ) (6)

Since there are three capacity equations (X = G, E, AC) twelve parameters have to be determined by linear interpolation e. g. of test measurement data under stationary operating conditions as have been prepared by ILK. The determination of the characteristic parameters sX and rX from these values will be described in the following section.

As shown in the figure 2 the Task A is based in three main pillars to cover an overview of the state of the art in the field of TDHP. In this task all involved countries will produce country reports focused on the description of their heating and cooling markets, dividing the systems into two groups, under 100kW and above. Normally big powers correspond to industrial applications designed to solve specific problems, while systems with smaller capacities are mostly used to provide energy to residential houses or office buildings. In these cases, the possibility to find comparative values that make possible the efficiency evaluation of the facilities and the installed machines is quantitatively more important, especially if we take into account that approximately 40% of the energy demands of an developed country are used in the domestic and office market.

The results will not only be used to give a global overview of the market, but will also help to understand the restrictions and to notice the possible opportunities and barriers of the technology as well as country specific differences, due to different political situations, building codes with different energy saving levels, incentives and funds to be spent on renewable energies. (i. e: fiscal treatments, laws about the uses of the geothermal sources, laws about legionella, etc.)

Climate in southern Spain has been classified as Mediterranean. It is characterized by hot dry summers, mild winters and seasonal rainfall, all subject to local variations depending on each concrete location.

The average temperature usually oscillates between 7°C in winter and 30°C in summer, with seasonal rainfall in autumn and spring, which represents less than 500L/m2 per year. This reduced number of rainy days involves having more than 2900 Sun-hours per year.

|

Fig. 1a. Solar radiation in Malaga. Period 2001-2008 Fig 1b. Temperature in Malaga. Period 2001-2008 Source: Junta de Andalucia. Consejeria de Agricultura y Pesca |

As shown in the graphics above, this climate is optimal for the use of solar cooling systems which result essential in summer to keep comfort conditions into acceptable levels, because of the fact that the period of highest solar radiation matches up with the one of highest temperatures.

Various approaches to solar cooling have been proposed to date, with single stage absorption cooling driven by flat plate or vacuum tube collectors dominating the market. The hypothesis here is that double stage absorption cooling fired by heat obtained from parabolic trough collectors has better economics for mid — and large scale applications. To conduct a high level verification of this hypothesis capital costs associated with the respective solar fields and chilling energy yields are compared for a system with a peak chilling capacity of 500kWR. In order to confirm the viability of the thermal approach in comparison with the direct photovoltaic approach an equivalent vapour compression system is also considered where the electrical power would be generated by a photovoltaic system.

Table 1. : Comparison of capital costs associated with the solar field required to achieve a chilling power of

500kWR for single stage, double stage and vapour compression with PV.

|

Chiller Type |

Absorption — Single Stage |

Absorption — Single Stage |

Absorption — Double Stage |

Vapour Compression |

|

|

Chiller Capacity |

500 |

500 |

500 |

500 |

kW |

|

Chiller COP |

0.60 |

0.60 |

1.35 |

3.25 (electric) |

|

|

Energy Input Required |

833 |

833 |

370 |

154 (electric) |

kW |

|

Solar Field Type |

CPC |

Vacuum Tube |

Parabolic |

Photovoltaic |

|

|

Solar field oversizing [1] |

20% |

20% |

20% |

0% |

|

|

Chiller inlet temperature |

90 |

90 |

Over 160 |

— |

°C |

|

Peak Solar field efficiency |

48% |

55% |

60% |

13% (electric) |

|

|

Solar field size required |

2’083 |

1’818 |

741 |

1’183 |

m[2] |

|

Price per m2 (installed) |

300 |

450 |

450 |

600 |

€/m2 |

|

Total price For solar energy source |

625’000 |

818’182 |

333’333 |

710’059 |

€ |

Capital costs for the solar field include delivery and installation. Costs associated with the preparation of the roof area to host the solar field structure are excluded. Capital costs for the chiller equipment and interconnecting pipe work and heat exchangers are not taken into account. In the same token on the PV side the inverter system and interconnection to the network are excluded. Efficiency figures are those applicable for generic products available in the market. For the single stage systems both a CPC and a vacuum tube collector system were considered, while for the double stage system the NEP Solar PolyTrough 1200 small aperture parabolic trough collector system was taken as a basis.

To estimate the annual cooling energy produced the three systems were modelled with varying degrees of detail for a location in southern France.

Modelling single stage system: Collector field energy yield is derived from general annual energy yield figures published in the industry and adjusted to site location

Modelling double stage system: The energy yield is calculated on the basis of an hourly model taking into account sun position, solar collector performance (optical material properties, thermal loss coefficients, IAM), chiller part load performance, inertia & heat-up losses as well as availability losses.

Modelling vapour compression system with PV: The annual cooling energy is approximated by the specific annual electrical energy yield for the photovoltaic panels times the average COP value of the vapour compression system of 3.25. The specific annual electrical energy yield for south of France is estimated at 1’450 kWhelec / kWinstalled.

The following table shows the results of the energy yields modelling for a location with the following site parameters (Marseille, south of France):

Latitude: 43°

Global radiation on a tilted plane: 1’865 kWh /m2 and annum DNI radiation: 1’775 kWh/m2 and annum

Table 2. : Comparison of the estimated cooling energy yield obtained from the 500kW single stage, double

stage and vapour compression systems for a typical meteorological year in the south of France.

|

Chiller Type |

Absorption Single Stage |

Absorption Double Stage |

Vapour Compression |

|

|

Chiller Capacity |

500 |

500 |

500 |

kW |

|

Chiller COP |

0.60 |

1.35 |

3.25 (elec) |

|

|

Solar Field Type |

Vacuum Tube |

Parabolic |

Photovoltaic |

|

|

Total net cooling energy generated |

630 |

645 |

600 |

MWh |

|

Cooling energy / solar field costs |

0.77 |

1.94 |

1.02 |

kWh/€ |

From the first order capital cost comparison of Table 1 and the energy yield comparison of Table 2 it results that double stage absorption cooling is the most economical avenue for solar cooling. The ratio of cooling energy to solar field costs as proxy of economic attractiveness is almost double for the parabolic trough approach. The double benefits of higher COP of the chiller and good solar collection efficiency due to concentration and tracking result in an overall better performance of this combination.

It has to be noted that the fraction of direct radiation versus diffuse radiation in the total radiation available has an influence on the comparison between low temperature non-concentrating and high temperature concentrating approaches. The more the direct fraction of the radiation increases over the diffuse the more the use of concentrating collector systems makes sense. Maybe this partially explains why many of the solar cooling systems installed in Germany for instance use non concentrating collectors. With the solar cooling market developing in southern regions where DNI radiation is higher we expect to see a strong take-up of concentrating solar collector fields driving double stage chillers or similar high temperature / high COP refrigeration systems

|

The impact of varying supply inlet temperature and inlet relative humidity at regeneration humidity matching supply air conditions (varying regeneration air humidity) are shown in the following graphs. This is equivalent to using supply air at ambient conditions, heat it up to regeneration temperature and use it for regeneration purposes. Therefore, the difference in absolute humidity between supply and regeneration air flow is zero.

Figure 6. Moisture removal in supply air stream for

varying supply inlet humidity and temperature at 50°C

regeneration temperature.

Figure 6 shows the moisture removal for 50 degC regeneration temperature. At supply inlet conditions of 40°C/95% RH the maximum moisture removal was measured at 5.1 g/kg d. a.. In this point the driving temperature difference is only 10K between supply and regeneration air, however the difference in absolute humidity between supply and regeneration air is zero. Figure 7 shows the results for a regeneration temperature of 80 degC. Here, the maximum moisture removal at supply inlet conditions of 40°C/95% RH was measured at 14.5 g/kg d. a., the difference to Figure 6 being the higher driving temperature difference. It can be seen in Figure 6 and Figure 7 that the moisture removal is considerably lower using heated ambient (supply) air for regeneration purposes, even though the regeneration air is supplied at the same temperatures as that in Figure 4 and Figure 5. This is mainly due to the higher humidity in the regeneration flow. The moisture removal capacity of the desiccant wheel is now mainly determined by the temperature difference between supply and regeneration flow since absolute humidity of supply and regeneration air is equal.

3.1. Silica gel comparison

Two standard materials used for desiccant wheels are silica gel and lithium chloride, with silica gel being the more popular of the two. One aim of this study is therefore to compare the performance of a FAM-Z01 material wheel to a standard silica gel wheel. Eicker et. al [9] investigated the moisture removal of a silica gel wheel over varying wheel speed and regeneration temperature. Their data is

used for the comparison, Figure 8. Eicker et. al tested the silica gel wheel at the conditions given in Table 1. The wheel had a diameter of 1000mm and flow rates of 1500 and 2000 m3/hr were used for regeneration and supply air, respectively. The FAM-Z01 wheel has a diameter of 300mm, hence the flow rates used in the presented work have been reduced as given in Table 2. However, the ratio of regeneration to supply air flow of 0.75 has been kept in the FAM wheel experiments to allow comparison with the results from Eicker et. al. All experiments were undertaken in counterflow mode.

|

Constant parameter |

Unit |

FAM- Z01 |

Si-Gel |

|

Wheel diameter |

mm |

300 |

1000 |

|

Supply inlet temperature |

°C |

32 |

32 |

|

Supply inlet humidity |

g/kg d. a. |

12 |

12 |

|

Supply air flow |

m3/hr |

447 |

2000 |

|

Regeneration air flow |

m3/hr |

335 |

1500 |

|

Regen. air inlet humidity (60°C) |

g/kg d. a. |

6.5 |

7.5 |

|

Regen. air inlet humidity (75 °C) |

g/kg d. a. |

7.5 |

7.2 |

|

Table 1. Constant parameters for results shown in Figure 8. Silicagel data from [9] |

![image154 Подпись: Figure 8. Comparison of moisture removal for varying wheel speeds and regeneration temperature in a silica gel and FAM-Z01 wheel. Silica gel data from [9].](/img/1154/image154_0.gif) |

It can be seen in Figure 8 that the moisture removal in the FAM-Z01 wheel is always greater than in the silica gel wheel for the same conditions. The silica gel exhibits a considerable drop in moisture removal at lower wheel speeds while the FAM material shows almost no drop for 60 °C and only a small drop for 75 °C. At a wheel speed of 20 revelations per hour the FAM wheel has a 48% higher moisture removal at 60°C and a 39% higher moisture removal at 75°C regeneration temperature. This excess moisture removal becomes smaller at the highest wheel speed of 85 1/hr. There, the FAM wheel has a 9% higher moisture removal at 60°C and a 4% higher moisture removal at 75°C regeneration temperature.

CSIRO Energy Technology is developing a small-scale desiccant-based air-conditioning system for residential applications. In this context, a desiccant wheel made of FAM-Z01 has been experimentally tested for its dehumidification performance.

It was found that for constant regeneration humidity the maximum moisture removal capacity of the material is 17 grams of water per kg dry air at 50°C regeneration temperature and 24 grams of water

per kg dry air at 80°C regeneration temperature from an inlet air stream of 40 °C and 95% relative humidity. The difference in moisture removal between 50 and 80°C regeneration temperature for supply inlet temperatures between 10 and 30°C and supply inlet relative humidity between 20 and 50% was found to be less than 1 g/kg d. a. This shows that a regeneration temperature of 50 °C can almost achieve the same moisture removal at lower inlet humidity supply air.

At varying regeneration humidity (matching ambient conditions) it was found that the moisture removal is considerably lower, even though the regeneration air is supplied at the same temperatures like in Figure 4 and Figure 5. This is mainly due to the higher humidity in the regeneration flow. The moisture removal capacity of the desiccant wheel is mainly determined by the temperature difference between supply and regeneration flow since absolute humidity of supply and regeneration air is equal. Maximum moisture removal was 5.1 g/kg d. a. and 14.5 g/kg d. a. for supply inlet conditions of 40°C/95% RH at 50 degC and 80 degC regeneration temperature, respectively.

The comparison with silica gel performance data yielded a greater moisture removal of FAM-Z01 material under all conditions. At a wheel speed of 20 revelations per hour the FAM wheel has a 48% higher moisture removal at 60°C and a 39% higher moisture removal at 75°C regeneration temperature. This excess moisture removal becomes smaller at the highest compared wheel speed of 85 1/hr. There, the FAM wheel has a 9% higher moisture removal at 60°C and a 4% higher moisture removal at 75°C regeneration temperature.

[1] Jia C. X., Dai Y. J., Wu J. Y. and Wang R. Z. (2006). Experimental comparison of two honeycombed desiccant wheels fabricated with silica gel and composite desiccant material. Energy Conversion and Management 47 (2006), pp. 2523-2534

[2] Jia C. X., Dai Y. J., Wu J. Y. and Wang R. Z. (2007). Use of compound desiccant to develop high performance desiccant cooling system. International Journal of Refrigeration 30 (2007) pp345-353

[3] Tokarev M., Gordeeva L., Romannikov V., Glaznev I. and Aristov Y. (2002). New composite sorbent CaCl2 in mesopores for sorption cooling/heating. Int. J. Therm. Sci. 41 (2002) 470-474

[4] Cui Q., Chen H., Tao G. and Yao H. (2005). Performance study of new adsorbent for solid desiccant cooling. Energy 30 (2007), pp 273-279

[5] Restuccia G., Frenia A., Vastaa S. and Aristov Y. (2003). Selective water sorbent for solid sorption chiller: experimental results and modelling. International Journal of Refrigeration 27 (3) 2004, pp. 284293

[6] Kakiuchi H. (2004). Novel zeolite adsorbents and their application for AHP and desiccant system. Proc. of IEA Expert meeting, IEA Annex 17, Advanced Thermal Energy Storage Techniques, April 18-20 2004, Kizkalesi, Turkey.

[7] Oshima K., Yamazaki M., Takewaki T., Kakiuchi H. and Kodama A. (2006). “Application of Novel FAM Adsorbents in a Desiccant System”, KAGAKUKOGAKURONBUNSHU, Vol. 32, pp.518-523 (in Japanese).

[8] Belding W. A., Delmas M. P.F. and Holeman W. D. (1996). Desiccant aging and its effects on desiccant cooling system performance. Applied Thermal Engineering 16 (5) pp 457-459

[9] Eicker U., Huber M., Schurger U., Schumacher J. and Trinkle A. (2004). Simulation and operation of sorption supported air-conditioning with air collectors in a European comparison. Proc. of 3rd Symposium Solar Cooling, University of Applied Science, April 26-27 2004, Stuttgart, Germany.

Conventional desiccant cooling system is comprised basically of a desiccant rotor, a sensible heat rotor, and a direct evaporative cooler. In this system, the process air to be supplied to the conditioned space is first dehumidified flowing though a desiccant rotor. The process air then passes a sensible heat rotor to be cooled sensibly by transferring heat to the outdoor air. Lastly, the process air is cooled further flowing through a direct evaporative cooler and supplied to the conditioned space. However, since the air is humidified through the direct evaporative cooler, the process air needs to be dehumidified at the desiccant rotor that much more in addition to the dehumidification for the latent load removal. This causes a large dehumidification load of the desiccant rotor and subsequently large thermal energy input to regenerate the desiccant rotor to deteriorate the thermal efficiency of the system.

Meanwhile, it is known that the air can be cooled evaporatively without an increase in the humidity in a regenerative evaporative cooler (REC)[4-8]. Basically, the REC is comprised of a pair of dry and wet channels as shown in Fig. 1(a). The process air flowing through the dry channel is cooled down by transferring heat to the adjacent wet channel. At the outlet end of the channel, a portion of the air is extracted and redirected to the wet channel, while the remaining portion is supplied to the air conditioning space. The extracted air flows through the wet channel in the opposite direction to the air stream in the dry channel and becomes colder than the process air in the dry channel due to the water evaporation from the wet surface. The temperature difference between the channels then causes heat removal from the dry channel to cool the process air stream. The air flowing out of the wet channel is exhausted to the outdoors. This cooling process is summarized in a psychrometric chart, Fig. 1(b). It is seen that the specific enthalpy change of the wet channel air flow is much larger than that of the dry channel air flow. For the energy balance between the channels, 1/5~1/3 of the process air is enough for extraction to the wet channel and the rest of the process air can be supplied to the conditioned space.

|

As can be inferred from Fig. 1(b), the REC is able to cool the incoming air down to its inlet dewpoint temperature even without an increase in the humidity. Consequently, when applying the

(a) schematic of the regenerative evaporative cooler (b) psychrometric chart

Fig. 2. Desiccant cooling system incorporating a regenerative evaporative cooler.

REC instead of the DEC, the humidity of the air at the inlet of the evaporative cooler dose not need to be so low as that in the system with a DEC to get the same outlet temperature. This fact implies that a substantial decrease in the dehumidification load of the desiccant rotor can be achieved by applying a REC.

Figure 2 shows the schematic of the desiccant cooling system with a REC and the corresponding psychrometric chart. The basic configuration of the desiccant cooling system with a REC is the same as the system with a DEC except for the application of the REC instead of the DEC. Incorporating a simple direct evaporative cooler at the end of the REC can reduce further the supply air temperature by 2 or 3oC.

In this study, a prototype of the desiccant cooling system incorporating a regenerative evaporative cooler was designed, fabricated and tested for the performance evaluation. The prototype was designed to show 4 kW cooling capacity at the ARI condition (indoor: 27oC, 50%RH, outdoor: 35oC, 40%RH) with the hot water supply of 70oC as the heat source. The ventilation ratio was determined to be 0.3, that is, the supply air comprises of 30% outdoor air and 70% recirculation air. To this purpose, two important components, i. e., the regenerative evaporative cooler and the desiccant rotor were developed and tested before being assembled into the system.

Night cooling is mainly provided by means of natural ventilation driven by a solar chimney in order to increase night time ventilation rates. During the day the sun heats up the black-painted upper-part of the chimney situated on the building roof, which creates an updraft of air in the chimney. Airflow between the solar chimney and the building zones is controlled by motorized dampers which are closed during the day. At night, the dampers open to let the updraft of air create a naturally circulating cooling air flow by extracting the warm air from the zones and renew it with cooler outside air. At the Almeria building, the solar chimney-driven natural ventilation is limited to the office zones, where the highest heat gains are observed.

|

Fig. 1. Solar collector of one of the solar chimneys. |