Как выбрать гостиницу для кошек

14 декабря, 2021

Jesfis Lopez-Villada*, Joan Carles Bruno, Alberto Coronas

Universitat Rovira i Virgili, CREVER — Group of Applied Thermal Engineering, Mechanical Engineering Department, Avda. Paїsos Catalans, 26, 43007-Tarragona, Spain Corresponding Author, iesus. lopez@urv. cat

Abstract

In this paper different solar cooling thermal plant design alternatives are analysed for their integration into a District Heating and Cooling (DHC) network based on a trigeneration plant using natural gas reciprocating engines. This facility is planned to be located in Cerdanyola del Valles (Barcelona) in the framework of the Polycity project (Concerto Programme) [1].

The purpose of the solar plant is to provide cooling to the DHC network users in order to reduce the primary energy consumption and the environmental impact caused by the energy generation system.

The solar cooling plant design alternatives are modelled in TRNSYS considering different types of solar thermal collectors and thermal chillers. For the modelling of the thermal chillers a new mathematical approach has been developed and implemented in the TRNSYS simulation platform. This approach is based on a modified characteristic equation method presented by Ktihn and Ziegler [2]. With this method a mathematical correlation of available catalogue data of different manufacturers is generated for each absorption and adsorption chiller.

Finally, in order to select the best option from an energy and economic point of view, the energy results and costs of the different alternatives are estimated and compared with the results of a previous study.

Keywords: Solar cooling, adsorption chiller, absorption chiller, TRNSYS

The POLYCITY project, funded by the EU-programme Concerto, focuses on large scale urban developments where living and working areas are integrated to result in sustainable city quarters [1]. The Catalonian project focuses on a large urban development in the community of Cerdanyola del Valles close to Barcelona. Almost two million square meters of buildings will be constructed within the next decade. Industrial and services buildings will be supplied with a very innovative energy system including a district heating and cooling network that is foreseen to integrate different subsystems. One of these is a large scale solar thermal cooling plant, the design, performance and economics of which are analysed in the present study.

The main objective of this analysis is to decide which is the best solar collector-thermal chiller combination for the large scale solar plant. In order to improve the results of this analysis compared to a previous study [3], a more accurate mathematical model of the thermal chillers is used. In addition, due to the economic analysis is very sensitive to the specific costs of the thermal chillers, we considered more real values of these coefficients according to the information found in the references [5] [6] [7].

In this work, the well-known transient simulation program TRNSYS [4] is used. Three types of solar thermal collectors and a total of four types of sorption chillers of different technologies (absorption and adsorption) and different chilling capacities are considered. It should be remarked that to perform this analysis we developed and implemented in the TRNSYS platform a new model (type 811) for both the adsorption and absorption thermal chillers. This model is based on the modified characteristic equation method presented by Ktihn and Ziegler [2]. With this method a mathematical correlation of available catalogue data of different manufacturers is generated for each adsorption and absorption chiller.

Regarding to the economic analysis, this is performed considering the total initial investment cost necessary to produce 700 MWh of chilled water.

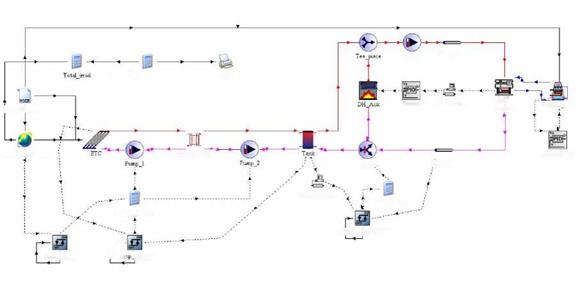

Fig. 1 shows the model developed in the TRNSYS environment for one of the options analysed. The main components of this model are the meteorological data file, the solar thermal collector system, the sorption chiller, the cooling tower, the buffer tank and the control system.

Three solar collector types are analysed in this study: Flat Plate Collector (FPC) (Sonnenkraft SK — 500), Evacuated Tube Collector (ETC) (Thermomax Memotron TMO 600) and Compound Parabolic Collector with Evacuated Tube Collector (ETC-CPC) (Sydney SK-6). The collectors are considered facing true South (azimuth = 0°) with a tilt angle of 35°, in order to obtain the maximum solar energy yield.

ON_OFF_3way_valve

ON_OFF_3way_valve

Figure 1. Basic TRNSYS’s diagram of the model for the solar cooling system with ETC collectors and an

ad/absorption chiller.

We selected as absorption chillers the single-stage hot water chillers BROAD BDH-50 and BDH-65 with a chilling capacity of 512 and 768 kWc respectively. For the adsorption option we selected a group of two MYCOM ADR-80 with a total capacity of 560 kWc and another of two ADR-60 with 422 kWc. In all the simulated cases the chillers operate with a temperature gap of the chilled water of 12°C / 7°C, the volume of the buffer tank was set to 10 m3 and the cooling tower modelled was the closed type Baltimore FXV-364-31N.

The control consists of the elements detailed below:

• A controller of solar radiation.

• A temperature differential controller between the solar collector field and the buffer tank.

• A temperature differential controller between the buffer tank and the outlet temperature of the generator of the chiller.

• A PID controller for the chilled water outlet temperature adjusted to 7°C which operates increasing or decreasing the auxiliary heat provided by the DH network.

• A PID cooling tower control adjusted to maintain the outlet cooling water temperature as low as possible with a minimum of 22°C.