Как выбрать гостиницу для кошек

14 декабря, 2021

G. Zorer Gedik1* and A. Koyun2

1Yildiz Technical University, Architecture Faculty Istanbul /Turkiye

2Yildiz Technical University, Mechanical Engineering Fac., Istanbul /Turkiye,

Corresponding Author, gzorer@hotmail. com

Abstract

In this study the experimental results of a solar energy collector which is installed to a south classroom window of a school in Istanbul are presented. The collector unit had been tested experimentally and numerical to determine its thermal performance before its integration into the south window. In this paper, the experimental analyze will be given in detail. The collector is tested using infrared radiation lamps in the laboratory. The collector reaction to change in the value of heat transfer is measured. Air temperatures and velocities are measured at the bottom (air entry) and top (air exit) of the collector. Moreover, performance of the collector geometry is analyzed using Computing Fluid Dynamics (CFD). The results of the measurements and theoretical analysis are compared. The back face of the collector is insulated to generate effective convective air flow on the basis of the test results. Then thermal efficiency measurements were executed in the classroom and the efficiency curves displayed and evaluated. A computer system with a software was designed to obtain air temperatures, velocities and solar radiation data in the classroom.

Keywords: Solar heating, solar collector, experimental, collector geometry.

A research project supported by TUBITAK (The Scientific and Technical Research Council of TUrkiye) is designed to improve the thermal efficiency of classroom design through the use of solar energy. [1] This paper presents a part of the results of the project. A solar energy collector was attached to a south classroom window of a school in Istanbul which has existing large classroom windows. The main components of the solar air collector are the glazing, the air space between the glazing and the collector plate, the aluminum collector profiles with air chambers and the insulated backing of the collector. (Figure 1) The function of the glazing is to admit as much solar radiation as possible and to restrict the transmission of heat radiation back through the glazing so that the optimum greenhouse effect results. Hence, the existing single glazed in front of the collector in the classroom changed the special glazing has ninety-two percent transmittance of light. [2]

The wavelength selective coating is applied to the front face of the collector profiles that have a low emmisivity of energy in the infrared wavelengths. Since infrared energy flow makes up a large part of the total energy loss of the system through the glazing, selective surfaces is quite effective in improving performance. [3]

|

|

Figure 1:The detail of solar collector. Figure 2. The profiles of solar collector.

The whole automation system is mainly divided into two parts: one part is the hardware equipments consisted of all kinds of devices used in the testing system; the other part is the software program based on Labview language. I/O device is used to connect hardware with software. Through the automation system the test system need to be operated normally and accurate measurement is also acquired. Because of the strict requirements under the test conditions according to ISO 9459-2, the system needs to accurately identify solar time and determine the test process whether it is in a exactly true position in sequence. At the same time data acquisition system will be operated to collect and record data with real-time curve of all sorts of signals. After the whole test process is finished, all of data will be used to produce the test report. Therefore, the main purpose of automatic control system is to release the tedious labour work of the operator and develop a set of efficient and reliable system in order to measure and control the test system automatically. The system should also be reliable and stable in different conditions to guarantee the normal operation of the whole test system.

Following the new regulations, a three bedrooms autonomous zone must have a minimal collector area of 4 m2 independently of the climate zone were is located. From the simulations results mentioned in chapter 5.4 we took the maximum value for Esolar that was 2083kWh/year in Alandroal (I1V3). What happens if we would like to reach on the others localities the same energy achieved in this one? The results have showed that just one location can reach almost that value with the minimal required area (4 m2), the other need more area (Fig 2.). It was made also calculations to see what the maximal SCA without having significant energy dissipations (overheating). This means that adopting just the regulation minimal collector area we can be wasting solar energy in some climatic zones that could have more potential. Of course we could adopt more efficient collectors to reach a higher value but, as it usual, many designers are going to follow strictly the imposed area and even will try to reduce it to save in costs and to achieve an easily integration in roofs. Calculating the minimal collector area for the rest of the localities (maintaining the same collector efficiency) to reach the same Esolar of Alandroal, resulted, in most of them, panel area increments of 0,5 m2 to 2,5 m2. In face of this, it seems it would be more effective to evolve the requirements to a minimal Esolar value per household adapted to different climatic zones or groups of zones. This would permit a better energy efficient /cost collector selection with not less energy efficiency management.

|

|

|

|

|

Fig 2. — Maximum SCA / SCA to achieve the same Esolar in the nine different localities.

3. Conclusions

Without any doubts, the new Thermal Regulations brings new challenges for the building design and construction industry activities and represents a start point to further advances in building sustainability and energy efficiency. After analyse the critical aspects concerning the implementation of solar collectors in Portugal, it was noticed that collectors market has conditions nowadays to grow towards a solid and income-producing market. But other conclusions could be taken. Portuguese Civil Engineers project designers are still not sufficient prepared to deal with this new technology although they are struggling to adapt to regulations and looking for training. By other means, high education institutions should adapt their Civil Engineer courses to give more competencies in these matters. Also, an adequate selection of the equipment system turns out to be a very important procedure to meet the regulations requirements. The building water supply design project, principally for multi-residential buildings, is facing important conceptual changes. Also, a repair and maintenance building design project, so long discussed and requested, turns to be even more essential. Architects have also here a very important role on the integration of solar collector on buildings as they could, among other things, design roof tilt angles adapted to solar collector optimal angles. But we must not forget we need government polices to provide minimal guarantees to building sun exposure. Relatively to the minimal regulations collector area, it seems that adopting just this area we can be wasting solar energy in some climatic zones that have more potential. A minimal Esolar value per household adapted to different climatic zones could guide better the designers to get more project design quality. Finally, we realize that, much work must be done but the changes imposed by new regulations should be seen as an opportunity to take the initial steps to more effective energy efficient construction in buildings.

References

[1] European Union Directive 2002/91/CE of 4 of January 2003.

[2] Portuguese Government, Decree Law 80/2006 of 4th April.

[3] ADENE, INETI, SPES, APISOLAR, MEI, DGGE, Hot Water Program for Portugal (IP-AQSpP), www. aguaquentesolar. com.

[4] DGGE & Ministry of Economy and Innovation (MEI), (2008) Portugal Efficiency 2015 — National Plan for Energy Efficiency (PNAEE), DGGE & MEI, Lisbon.

[5] Weiss, W., Faninger, G, (2002) Solar Thermal Collector Market in IEA Member Countries, IEA Solar Heating & Cooling Programme, Austria.

[6] Portuguese Observatory for Solar Thermal, (2003, 2004, 2005, 2006) Characterization of Solar Thermal in Portugal, ADENE & IP-AQSpP, Lisbon.

[7] National Institution for Energy and Geology (DGGE), (2004) The Solar Collectors Use for Domestic Water Heating, DGGE & IP-AQSpP, Lisbon.

[8] NHBC (2007), Guide to Renewable Energy, NHBC Technical, Amersham, Bucks, UK.

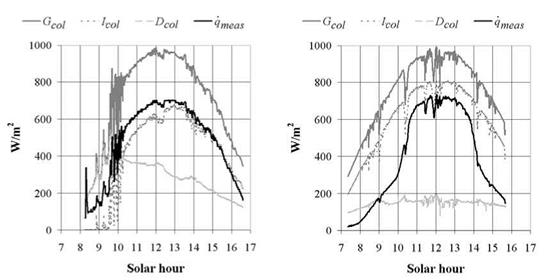

The comparison of experimental and calculated instantaneous power results, obtained after the different approaches presented in the previous section, is based on instantaneous efficiency measurements for a CPC collector (C = 1.72), as well as on their corresponding steady-state and dynamic efficiency curve parameters. The measurements were made at the Institute for Thermodynamics and Thermal Engineering (ITW) of the University of Stuttgart, Germany.

Two measurement periods were chosen, allowing the validation of power calculation methodologies under different radiation conditions. Values of radiation measured on the collector aperture plane (tilt = 48°, azimuth = 5°, latitude = 50°, albedo = 0.2) and measured instantaneous power values are represented in figures 1a) and b) for both periods. In the first measurement period, the collector was positioned on an EW orientation, whereas in the second period the collector was on a NS orientation.

|

|

|

|

|

Considering the use of the power correction methodology proposed by Horta et al. (2008) in power calculations after steady-state efficiency test parameters, average diffuse radiation fractions of 0.3 and 0.25 are estimated for the first and second measurement periods, respectively.

It is important to refer, at this point, that not all data presented in the previous figures would be usable for a steady-state test. Actually, as the name suggests, the steady-state test methodology is based upon a collector heat balance assuming stationary conditions.

Furthermore, it must be cleared that these same measurement periods based the determination of the dynamic efficiency curve parameters used in the calculations to follow.

4.1. Test of a flat plate collector

A selective flat plate collector was tested according to QD test methodology. In order to analyse the test sequences, graphs were generated according to the recommendations of the standard EN 12975-2 section 6.3. These graphs are represented in Fig. 1.a), b) and c).

|

Analysis of the graph in Figure 1a) shows that the test was conducted within the expected working temperature range of the collector. This meets the requirement to have at least 4 fluid inlet temperatures evenly spaced in the collector’s working temperature range. One of the tests was conducted under conditions in which the collector’s mean fluid temperature stood at ± 3 K of ambient temperature, around solar noon, so as to make possible a precise determination of n0.

The parameter identification using the developed the MLR tool gave the results listed in Table 1.

|

Table 1: Parameters determined with MLR analyses

|

As already referred, the fact that not enough cloudy conditions were included in the test sequences may have induced the determination of values of b0 and Kd, which are not in agreement with the expected values for a flat plate collector.

Also the parameter c5 shows a very low value, maybe as a result of not enough transient data included in the test sequences. Although individually the parameter values are not completely in agreement with the expected values, de comparison of the power curves — measured and calculated using equation (8) and the parameters of Table 1, shows very good agreement. This is shown in Figure 2.

|

|

Figure 2 — Comparison of calculation of Q/A using the model with lab results.

Sylvain Lalot[1]*, Soteris Kalogirou[2], Bernard Desmet1, and Georgios Florides2

1LME, Universite de Valenciennes et du Hainaut Cambresis, Le Mont Houy,

59313 Valenciennes Cedex 9, France

2Cyprus University of Technology, P. O. Box 50329, 3603 Lemesos, Cyprus

* Corresponding author, sylvain. lalot@univ-valenciennes. fr

Abstract

The objective of this work is the development of an automatic solar water heater (SWH) fault diagnostic system (FDS). The latter consists of a modelling module and a diagnosis module. A data acquisition system measures the temperatures at four locations of the SWH system (outlet of the water tank; inlet of the collector array; outlet of the collector array; inlet of the water tank). In the modelling module a number of artificial neural networks (ANN) are used, trained with the very first values when the system is fault free. Then, the neural networks are able to predict the fault-free temperatures and compare them to actual values. When the differences are low, the corresponding networks are unchanged. On the contrary the networks are retrained. Then the diagnosis module analyses the difference between the current connection weights and the initial weights. When a persistent significant modification occurs, a flag is set to signify that a default is present in the SWH.

The system can predict three types of faults: collector faults and faults in insulation of the pipes connecting the collector with the storage tank (to and from the tank) and these are indicated with suitable labels. It is shown that all faults can be detected well before the end of the drifts, without any false alarm, when the networks and thresholds are well tuned and that the observation window has the right size. It is shown that this does not depend on the draw off profile.

Keywords: fault diagnostic, model adaptation, neural network, water heating system

type. As it has been shown that continuous drifts can be analysed by neural networks in heat exchangers [3-5], ANN has been chosen here to test such tools. In particular, a method based on neural models is presented according to the study detailed in [6] which shows that a continuous assessment of a model and its adaptation is efficient. In a first part, the solar system is presented along with the drifts that are taken into account. The drift detection tool is detailed in the second part, and results are given in the third part.

J. Fan*, J. Dragsted, S. Furbo

Department of Civil Engineering, Technical University of Denmark,

Brovej 118, DK 2800, Kgs. Lyngby, Denmark

Corresponding Author, iif@byg. dtu. dk

Abstract

During three years seven differently designed evacuated tubular collectors (ETCs) utilizing solar radiation from all directions have been investigated experimentally. The evacuated tubular solar collectors investigated include one SLL all-glass ETC from Tshinghua Solar Co. Ltd, four heat pipe ETCs and one direct flow ETC from Sunda Technolgoy Co. Ltd and one all-glass ETC with heat pipe from Exoheat AB. The collectors have been investigated side-by-side in an outdoor test facility for a long period. During the measurements, the operating conditions — such as weather conditions and temperature of the inlet fluid to the collectors have been the same for all collectors. The volume flow rate through each of the collectors is adjusted so that the mean solar collector fluid temperature has been the same for all collectors. Thus a direct performance comparison is possible. The side-by-side tests were carried out with different mean solar collector fluid temperatures and in different seasons of the year. The results of the measurements are presented in this paper. The influence of the mean solar collector fluid temperature on the thermal performance of the different collector designs will be discussed. Further, the collector performances are compared for different times of the year and it is illustrated how the performance of the different collector types depends on weather conditions.

Keywords: Evacuated tubular solar collector, collector design, thermal performance, test.

In recent years the evacuated tubular collectors have gained an increasing share of the market. On the world’s largest solar thermal market, China, evacuated tubular collectors have increased the market share from 30% in 1998 up to 94% in 2007 [1]. In Europe, evacuated tubular collectors of up to 240,000 m2 were installed in 2007 [2].

On the market there is a large number of collector manufactures providing evacuated tubular collectors with a variety of types such as all-glass, heat pipe, all-glass with heat pipe, direct flow, with and without reflectors. As far as the heat pipe evacuated tubular collector is concerned, there are designs with different tube diameters and different shapes of the absorber. It is therefore important to know how the different designed evacuated tubular collectors perform. He et al. [3] made a comparison of optical performance of evacuated collector tubes with flat and semi-cylindrical absorbers. The collector tubes are utilizing solar energy from the front side. The absorbed energy of the absorber is used in the comparison. They found that the semi-cylindrical absorber outperforms the flat absorber by 15.9% annually if it is located at latitude 40° N. Fan et al. [4] carried out side-by-side outdoor tests of four heat pipe evacuated tubular collectors with a flat fin or a semi-cylindrical fin. The collectors

utilize solar radiation from all directions. The measurements show that at latitude 57° the ETC with a flat fin performs better than the ETC with a semi-cylindrical fin for a tube diameter of 70 mm and a collector tilt of 67°. The ETC with flat fin tends to perform better than the ETC with the curved fin in winter and at high collector fluid temperatures.

Evacuated tubular collectors have a substantially lower heat loss coefficient than standard flat plate solar collectors. This makes ETCs very suitable for high latitude regions like the Arctic. The advantages of evacuated tubular collectors at high latitudes are not only their low heat loss and high efficiency, but also the ability to utilize solar radiation from all directions due to the large variation of the solar azimuth. The aim of this paper is to present the result of a long term outdoor test of differently designed evacuated tubular collectors utilizing solar radiation from all directions. Side-byside tests of seven differently designed evacuated solar collectors were carried out in a period from February 2006 to August 2008. The thermal performances of the differently designed evacuated tubular collectors are compared. Based on the observations from the measurement, it will be elucidated how the collector performance is influenced by the solar collector designs, the weather and operation conditions.

Seven differently designed ETCs utilizing solar radiation from all directions have been investigated experimentally. Detailed data sheet of the investigated ETCs is given in Table 1.

Side-by-side tests were carried out in an outdoor test facility at the Technical University of Denmark, latitude 56°N, see Figure 1. On the test platform, five collectors can be tested under the same conditions at a time. The collectors are directly facing south and have a tilt angle of 67° which is suitable for typical operation conditions in the Arctic. The collectors can utilize solar radiation from all directions. A glycol/water mixture of 41% by weight is used as the solar collector fluid. The fluid flow rate through each of the collectors is measured by a flow meter type Brunata HGQ1-R0. The inlet and outlet temperatures of the collector are measured by copper/constantan thermal couples, type TT. The difference between the outlet and inlet temperature is measured by a thermopile. The five collectors are parallel connected to a temperature control unit so that the inlet temperatures to the collectors are the same. A pump is used to circulate the solar collector fluid during all hours so that the inlet temperature of the fluid to the collectors is kept constant. The flow rates through the collectors are adjusted in such a way that the average temperatures of the collector fluids in all the collectors are approximately the same during the test. The accuracy of the absolute temperature measurement and temperature difference measurement is 0.5 K and 0.1K, respectively. The accuracy of the flow rate measurement is estimated to be 1.5%. The measurement data are monitored and logged every two minutes by LabView.

The weather data are measured in a climate station located on the roof of a building close to the test platform. The total and diffuse solar irradiance on horizontal surface and the ambient air temperature are measured.

The thermal performance of the ETCs were measured in the period from February 2006 to August 2008. The experiment is divided into three phases:

Phase 1: February 2006 — June 2006, collectors tested: ETC 1, ETC 2, ETC 3, ETC 4 and ETC 5.

Phase 2: July 2006 — May 2007, collectors tested: ETC 2, ETC 4, ETC 5 and ETC 6.

|

Phase 3: May 2007 — August 2008, collectors tested: ETC 2, ETC 4, ETC 5, ETC 6 and ETC 7. During the test period, four mean collector fluid temperature levels are used: 26°C, 43-47°C, 63-68°C and 75-78°C.

Fig. 1. The side-by-side test facility.

|

Table 1. Data of the tested evacuated tubular collectors.

|

One aim of the newly developed all-in-one test facility is to combine all three test methods in a single test facility. This test facility must be able to fulfil all requirements and qualifications resulting from the above mentioned standards.

The housing of the test facility is a conventional 20 foot office container. In this container the hydraulics of the temperature unit as well as the measuring equipment and the data logging instruments are located. In order to operate the facility independent from a cooling network, a chiller combined with a 600 litre cold water store is installed. With the exception of the chiller, all com-

|

ponents are located inside the container. Figure 1 shows the schematic layout of the major components.

The facility is designed in such a way that it allows for parallel testing of

• 4 collectors (according to EN 12975 / ISO 9806) or

• 4 systems according to ISO 9495-2 (CSTG-method) or

• 2 systems according to ISO 9495-5 (DST-method)

|

To realise these different test configurations, the hydraulic arrangement consists of one main loop that can be divided into six smaller loops by using several valves. These six loops are required for testing two solar thermal systems according to the DST-method at the same time. The hydraulics for testing according to ISO 9459-2 and ISO 9806 / EN 12975 consist of only one hydraulic loop, which can be used to test four systems (CSTG-method) or four collectors simultaneously. In figure 2, the layout of the complete hydraulic arrangement is shown.

On the left side of the diagram the four connections for testing the systems (ISO 9459-2, CSTG — method) or for the collectors (EN 12975) are located (1-4). For the DST-method (ISO 9459-5), connections for two collectors (1-2) including the two necessary connections to the solar collector loop (DST-solar 1-2) are depicted. The middle part of the hydraulic circuit is solely related to the DST-method, since there are the connections for the thermal auxiliary heating loops (DST-aux 1-2) and the storage tanks (DST-tap 1-2) of the two systems to be tested. The first heat exchanger (HX1) in flow direction offers the possibility to connect an optional external cooling net. If this is not available, the heat will be removed via the second heat exchanger (HX2), which is on the secondary side connected to the cold water store of the test facility. The cooling circuit also supplies the air conditioning unit inside the container test facility with cold water. On the right hand side of the vertical line, which symbolizes the wall of the container, the chiller is located.

|

This chiller is positioned outside the container because this allows a better supply of fresh air to the refrigerant condenser and reduces the noise level inside the container test facility. Figure 3 shows the chiller connected to the container of the test facility.

|

All hydraulic connections to the equipment being tested are located outside the container and are realized with conventional 1 inch screw fittings, countersunk into the container walls. In figure 4 the connections to the collectors / systems being tested are shown.

Since the energy label in Portugal is based on an evaluation of primary energy, equipments for ambient heating, ambient cooling and production of domestic hot water have, besides the envelope and the climate, a critical influence in the result. In order to analyse the influence of the equipments, several scenarios were considered, as listed in Table 4.

|

Table 2 : Main characteristics of case-studies (as in the base-cases)

|

|

Table 3: Main characteristics of the selected climates

|

|

Table 4: Heating, cooling and DWH equipment scenarios considered

|

![]()

|

1st International Congress on Heating, Cooling, and Buildings, 7th to 10th October, Lisbon — Portugal /

|

At present (summer 2008) approximately 430 different types of solar collectors and nearly 40 factory made systems are Solar Keymark certified. It is expected that two third of all solar thermal collectors sold in Europe are already qualified with a Solar Keymark /6/. A large number of the tests required for awarding the Solar Keymark were carried out at the Test and Research Centre for Solar Thermal Systems (TZS) located at the Institute for Thermodynamics and Thermal Engineering (ITW), University of Stuttgart.

6.1 Future development of Solar Keymark Certification Solar collectors

An assessment of the thermal performance of solar collectors directly on the basis of the efficiency parameters is not appropriate. Hence it is common practice to use the annual collector gain as a performance criterion, e. g. with regard to the qualification for subsidy programs. At present several national methods exist for the determination of the collector performance. This results in additional effort for manufacturers active in different European countries.

In order to overcome this problem, a method for the determination of the annual collector gains will be incorporated into the revised version of the Solar Keymark scheme rules.

Factory made systems

According to the current Solar Keymark scheme rules every factory made system has to be tested even if the system is part of a so-called system product line (or family respectively) and only differs in the collector area and/or the store volume. The huge effort resulting from this requirement is also the reason why the number of Solar Keymark certified collectors is approximately ten times higher than the number of certified systems. In order to overcome this problem a procedure was developed that allows the determination of the system performance of systems which are part of a system family by a mathematical procedure based on the test of only one system out of the product line /7/.

At present it is not finally decided if this procedure or an-other one /8/ based on the standard series EN 15316 (Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies) will be included in the final revised version of the Solar Keymark regulations.

Custom built systems

Custom built systems are standardised in the European standard series CEN/TS 12977. Since the major share of systems sold in central and northern Europe are small custom built systems, it is favourable to extend the Solar Keymark also to that category of systems. Due to the fact that Solar Keymark certification must, in principle, be based on EN standards this is quite difficult since a CEN/TS document is formally not considered as an EN standard. At present several options to overcome this problem are under discussion but, even in the optimal case, a solution can not be expected before 2009.

The current status and the latest developments related to standards for solar thermal products and to Solar Keymark certification were described. The revised version of the European standard series

EN 12975, EN 12976 and CEN/TS 12977 contains appropriate requirements and test procedures for the products on today’s solar thermal market

The large number of already certified products clearly shows the success of the Solar Keymark. The Solar Keymark is on the best way to be established as THE quality and qualification label for solar thermal products all over Europe.

The combination of the European solar thermal standards and Solar Keymark certification provides an excellent basis for the further development of as sustainable solar thermal market in Europe. In the long-term all involved players — customers, manufacturers as well as test laboratories and certification bodies — will benefit.

[1] Harald Druck, W. Heidemann, H. Muller-Steinhangen, A. Veenstra: European standards for thermal solar systems — the finals, Proceedings of ISES 2001 Solar World Congress, Pages 589 — 595, Adelaide, Australia, ISBN 0-9586192-7-1

[2] H. Druck, S. Fischer, H. Muller-Steinhagen: Solar Keymark Testing of Solar Thermal Products, Proceedings of ISES 2007 Solar World Congress, September 18 to 21, 2007, Beijing, China, ISBN 978-7302-16146-2, Tsinghua University Press, Beijing and Springer-Verlag GmbH Berlin Heidelberg, CD: ISBN 978-7-89486-623-3

[3] H. Druck, E. Hahne: European test standard for the performance characterisation of stores for solar heating systems, Proceedings of Terrastock 2000, Pages 285 — 290, Stuttgart 2000, ISBN 3-9805274-1-7

[4] M. Peter, H. Druck, Testing of controllers for thermal solar systems, Solar Energy 82 (2008), pp. 676-685

[5] CEN: Specific CEN Keymark Scheme Rules for Solar Thermal Products, Final version 8.00 — January 2003 (ed. J. E. Nielsen). Available via

http://www. estif. org/solarkeymark/Links/Internal_links/solar_keymark_scheme_8.00.pdf

[7] H. Kerskes, B. Mette, H. Druck, H. Muller-Steinhagen: The Solar-Keymark Testing for Factory Made Systems by Means of an Extrapolation Procedure, Proceedings of Eurosun 2008, October 7 to 10, 2008, Lisbon, Portugal, to be published

[8] EN 15316-4-3: Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 4-3: Heat generation systems, thermal solar systems

More information about the Solar Keymark is available at: www. solarkeymark. org.

The European Standards mentioned above are available from: www. beuth. de