Как выбрать гостиницу для кошек

14 декабря, 2021

As [2] describes, the solar installation is located in CARTIF Foundation Building 1, in Boecillo, Valladolid, in the middle of Spain. (Lat.41° 32’, Long -4° 45’)

There are in that building, a big amount of different heating and refrigeration systems to be used separately or by pairs. It makes possible the use of different control strategies to minimize energy consumption.

There are two meteorological stations too, used to store direct and diffuse radiation, ambient temperature, humidity, wind speed and direction accessible from the Web: www. cartif. es

There are two collector fields, each one with technologies, flat (37,5 m2) and vacuum tubes (40 m2). The second one is mounted on a platform with a single tracking azimuthal to maximize captured energy.

Due to the strong winter conditions, it’s necessary to add an anti-freeze fluid in the primary flow. To separate primary and secondary flows there is a counter flow heat exchanger.

In order to increase the difference between high and low temperatures, and improve the collectors yield, two storage tanks are connected in series.

It also there is a three-way valve between the flat plane and the vacuum tube storage to connect them in series too. Flat panel field will contribute to the system with hot water at a temperature level lower then the vacuum tube ones, because this yield must feed an absorption chiller (35 kW).

There is a natural gas boiler connected in series to produce hot water when the solar system is not able to contribute. Apart from it there is too a cooling tower for the condensation.

As described on [3] to reach our energy objectives, every cooling or heating machine is completely monitored. Temperatures and flows of each machine are stored in a computer through a Lonwork Network. Depending on the use of that values, can be gathered every second, ten seconds or minute.

M. Lundh1*, I. Vassileva2, E. Dahlquist2 and E. Wackelgard1

1 Department of Engineering Sciences, The Angstrom Laboratory, P. O. Box 534, SE-751 21 Uppsala, Sweden

2 School of Sustainable Development of Society and Technology, Malardalen University, P. O. Box 883,

SE-721 23 Vasteras, Sweden

* Corresponding Author, Ma gdalena. Lundh @ angstrom. u u. se

Abstract

There are different methods to display energy use for hot water in households. The most direct method is to measure domestic hot water, but at present there is a lack of detailed measurements.

An alternative method is to model load curves. In this paper a model based on time-geographic data is evaluated by comparison to hot water use measured in two multi-family houses. Variations in demand are also studied to investigate possible model improvements. The results show that the modelled and measured daily energy demand agree rather well, both in magnitude and in distribution in time. Further investigations of measured data show that the distributions over the day coincide well for all investigated months, while a clear minimum in energy demand is found during vacation time in July and August. Comparison between different weekdays does not show any clear pattern. The findings can be used to further improve the model to include weekly and seasonal variations. The modelled profiles will later be used to investigate the influence of different draw-off pattern on solar heating utilization.

Keywords: DHW load profiles, model, time diary, measurement

When performing solar heating simulations, rather simple hot water consumption profiles are usually used. The dynamic behaviour of household members is reduced to a schematic load profile, often assuming three draw-offs per day, not distinguishing between weekdays and weekend days or seasonal variations. To dimension a solar heating system correctly the actual hot water use in a building is however preferably applied. Different methods can be used to display energy use in households. The most accurate method to display the current use is to make measurements, but even measured data may not be useful to estimate future hot water demand. Moreover, it is costly to measure hot water use in detail and it often requires severe interference in the apartment if all different tap places are to be monitored separately. Few detailed hot water measurements have been performed so far, with the exception of a survey performed by the Swedish Energy Agency, ending in January 2008 [1]. Energy was however only measured in ten households, which is too few to be statistically significant.

Another approach to estimate hot water use is to model load curves. One method to generate hot water profiles was developed within IEA-SHC Task 26 on statistical means [2], which has been applied in several different studies. Models have also been developed for predicting domestic hot water load for Swedish conditions, such as Wollerstrand [3] based on Holmberg [4], using stochastic variables

derived from measurements. However, the existing models seldom focus on the influence of the individual household members and their behaviour. The method developed at Uppsala University, also reported in detail in [5, 6], and evaluated in this study, on the other side, is based on time-geographic studies by using data from so called time diaries to quantify hot water demand. It enables direct analysis of the correlation between actual behaviour and energy use. A certain energy demand can then be directly connected to a specific activity or user pattern, and since all household members record time diaries for the same days, the energy use can in addition be connected to a certain person.

1.1. Aim

The main aim of this study is to compare hot water user profiles modelled from time-use data with measurements in Swedish apartment households, but also to study how hot water demand varies in the measured households over the year. The results can then be used to further improve the model. The work is based on two different studies, one comprising measurements of domestic hot water use [7] and the other on development of a method for generating hot water load profiles [5, 6].

1.1. Outline

The two studies constituting the background of the comparison are first introduced. The comparison of the measured and modelled load profiles are then presented, as well as the variation in measured hot water demand during different periods of the year. Finally, the results, as well as possible improvements of the model, are discussed and concluding remarks given.

In this study, two different approaches for generating hot water profiles have been compared; measurements in apartment households and modelling of hot water profiles from time-use data recorded by apartment household members.

There is no pressure drop calculation in Type1223new, but this is important for optimizing the heat exchanger configuration. Therefore, a pressure drop calculation was added to the model.

The airside pressure drop is determined from corresponding empirical friction factor correlations [10-13]. The friction factor f includes a Fanning friction factor[10] and parts of entrance and exit pressure drops, which are associated with irreversible free expansion that follows a sudden contraction or an abrupt expansion, compare with [18].

With the friction factor f the pressure drop is calculated as

|

|

The liquid-side pressure drop in the model consists of a pressure drop in the passes (flow friction) and in the pass bends (form drag effects). The friction factor for tube passes is calculated according to the equation of Colebrook and White with typical roughness height for new copper tubes of 0.0013 mm [19]. The equation of Colebrook and White and an equation for friction factor of 180° bends can be found in almost any fundamental hydrodynamics book and will not be described here.

C. Sole, M. Medrano, M. Nogues, L. F. Cabeza*

GREA Innovacio Concurrent Edifici CREA, Universitat de Lleida, Pere de Cabrera s/n, 25001-Lleida (Spain)

Phone: +34-973 003576, Fax: +34-973 003575 Corresponding Author, [cabeza@diei. udl. cat

Abstract

Simulations were done to check the behaviour of a PCM integrated into the storage tank of a solar combisystem (system that provides energy for DHW and space heating (SH)). The meteorological conditions chosen for the simulations were the Spanish climate of Madrid. The building selected is a single-family two storey house with an energy demand of 60 kWh/m2-year. These simulations were done with a tool developed within the framework of the Solar Heating and Cooling (SHC) Programme of the International Energy Agency (IEA). The main topics studied in these simulations were the behaviour of the PCM and the storage configuration. The aim of these simulations was to check whether the advantages of PCM observed experimentally in a real solar pilot plant for DHW demand are still valid in a more complex system such as a solar combisystem. It was shown that the position of the output to the heating system is a crucial point for the final performance of the system since its position benefits the DHW demand or the heating demand. With the system designed as it is and the control applied (typical differential control for simple water tank), no better results were obtained for a PCM-water store compared to a water store regarding the performance indicators used. Penalties are accounted when the demand of DHW or space heating is not fulfilled. It is seen that the introduction of PCM helps to decrease ore completely avoid the penalties for not reaching the comfort conditions in the demand.

Keywords: Phase Change Material, simulation, combisystem, energy storage

Obtaining high storage energy systems seems to be one of the key parameters to promote the use of renewable sources. Due to the mismatch between energy generation and demand, the storage set-up is essential.

Phase Change Materials (PCMs) seem to be one of the most promising techniques that might lead to this high energy storage performance. A PCM is a material which stores or supplies heat at its melting/solidification temperature using its high thermal energy storage density per unit volume as a consequence of its latent heat, which is higher than the sensible heat. It is possible to use the latent heat of solid-gas, solid-liquid and liquid-gas transformation, however, only the solid-liquid transformation is used due to its lower volume variation [1].

The real behaviour of some PCMs was tested in the pilot plant of the University of Lleida [2-3] with a daily DHW demand. Some of the advantages of PCM were experimentally tested and showed its capability of reheating the cold water surrounding the PCM containers after a partial draw-off of the storage tank. Another advantage is that the temperature of the water next to the PCM module keeps constant or decreases slower than the water with no interaction with the PCM [4].

Simulations with a combisystem (system that provides DHW and space heating demand) have been carried out to test the PCM behaviour under such a complex system. The chosen climatic data were from the city of Madrid and the building simulated had an energy demand of 60 kWh/m2-year.

The aim of these simulations was to check if the advantages observed in a DHW system were still kept in a more complex system that provides DHW and space heating demand as it is a combisystem.

This work is included in the framework of the Task 32 of the Solar Heating and Cooling program of the International Energy Agency (IEA), and the system and boundary conditions were previously defined in this work group [5]. A simulation tool with TRNSYS was designed to perform easy and fast simulations by non-expert users to get clear and easy-to-understand results.

|

|

Results are including electricity consumption of different building devices including pumps for cooling and heating network (table 4). There is no huge variation between the three locations. These values are common for each case.

|

Auxiliaries sum (primary) |

Auxiliaries sum (elec. cons.) |

Hot pump |

Cold pump |

FCU Fans |

Vent Offices |

Vent Meeting |

Appliances |

Light |

|

|

Paris |

180.03 |

72.01 |

1.09 |

13.21 |

8.08 |

0.96 |

2.76 |

25.56 |

20.36 |

|

Stockholm |

186.90 |

74.76 |

1.28 |

13.21 |

8.60 |

0.96 |

2.76 |

25.56 |

22.40 |

|

Lisbon |

176.90 |

70.76 |

0.70 |

13.21 |

6.96 |

0.96 |

2.76 |

25.56 |

20.61 |

|

Table 3. Auxiliaries consumption [kWh/(m2 year)] |

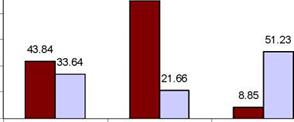

2.2. Heating and cooling load

These loads differ significantly between locations. Loads are not only including each thermal zone load but also losses due to heating and cooling network (fig. 3).

/

![]()

100.00

100.00

О

80.00

£

60.00

40.00

U)

20.00

2

0.00

Paris Stockholm Lisboa

□ Heating load □ Cooling load

Fig 3. Building heating and cooling load [kWh/(m2 year)]

In order to demonstrate uncertainty in modelling solar systems a large solar hot water system, is employed. A schematic diagram of the system is shown in Fig. 1. The system consists of a collector array, a storage tank, solar pump and auxiliary heater. A differential thermostat is used which compares the temperature at the exit of the collectors and the storage tank and gives a signal to switch on the pump. The collectors employed in this application are flat plate collectors. Their characteristics are shown in Table 1.

|

The characteristics of the solar system are shown in Table 2. These are obtained from an optimization exercise of the same solar system presented in [2].

|

Table 2 Characteristics of the hot water system

|

The solar system examined can satisfy the hot water needs of 10 houses or flats or any other similar application of same hot water requirement. For this application, a hot water consumption (load) profile is required. This load is subject to a high degree of variation from day to day and from consumer to consumer, however, it is impractical to use anything but a repetitive load profile. This is not quite correct for the summer period, where the consumption pattern is somewhat higher due to frequent bathing. However, during this period, the temperature requirement for hot water is not as high as during winter. Consequently, the total thermal energy requirement is reasonably constant throughout the year. For the present study, the hot water consumption profile, illustrated in Fig. 2 is used. The same daily hot water consumption profile, of 120 liters at 50°C, is assumed for each house (families of four persons, 30 liters/person).

|

Fig. 2 Hot water daily consumption profile for one family

Previous observation showed that the five fins collector achieved an increase in velocity of 2% compared to the four fin design, while longitudinal water temperature stratification decreased by 19%. This could be explained by the addition of the fins responsible for an increased transfer of heat inside the collector, thus increasing velocity and overall temperature in the collector.

In order to demonstrate that five fins is a more suitable arrangement geometry for optimal collector design, a 3D CFD analysis was carried out assuming a constant temperature boundary condition on the absorber plate set at 313°K. The fluid departure temperature was set at 293K. Despite the fact that the system is under constant heat flux, using a constant input temperature allowed the heat absorbed by both collector to be derived as shown in Figure 7.

Initially, for the first 10 minutes, more heat was absorbed by the five fin collector compared to the four fin. This is linked to a frenzy of heat transfer activity; the fins are surrounded by cooler water. An increase in heat transfer activity occurs when increasing from four to five fin geometries. After 10 minutes the five fins are surrounded with hotter water than the four fins are. The difference in temperature between the four fins and the water is higher resulting in a higher heat flux. Both profiles reach a peak value at the equilibrium temperature 313°K set as the boundary condition.

This paper reported the implementation of a four fin ICS-SWH concept utilising CFD-Fluent software through Gambit in order to optimise its design performance. Initial results of the four fin ICS-SWH indicated that one fin could be added to the original design to improve the heat transfer. A 3D CFD simulation was then undertaken for a five fin ICS-SWH. Two boundary conditions were applied to the systems in order to compare the water temperature stratification achieved and the heat transferred to the water body by each collector.

The first boundary condition applied to the systems consisted in a constant heat flux on the absorber plate. This method was used to characterise the temperature stratification and the velocity

magnitude within both collectors. Despite a minor decrease in temperature gradient between the top to bottom in the five fin ICS-SWH, it was clearly observed that stratification remained. It is important to state that the addition of fins should not impede the flow between the fins (as was experienced when trialling a multi-fin design in an earlier study), thereby reducing the convection coefficient. Results showed that the addition of one fin in the collector increased the velocity in the collector which has a corresponding increase on the Nusselt number; raising the heat transfer coefficient in a predictable manner [12]. The velocity magnitude was also observed to decrease with time for both collectors with the water getting warmer.

A second boundary condition applied to the systems consisted of a constant temperature on the absorber plate which was used to characterise the heat absorbed by each collector. Results revealed that the addition of one fin accounts for the increased transfer of heat inside the collector. It was observed that the five fins supplied more energy to the collector than four at the beginning of the charging process. The intermittent availability of incident solar radiation in Scotland shows high potential for this type of improvement as it is advantageous to have rapid heating process.

In light of the results presented in this paper, the five fin collector performed generally better than the original four fins collector. Therefore this new design could be suggested as a new arrangement of the collector assuming that the cost associate to this improvement is negligible.

[1] A. E. Gill, Journal of Fluid Mechanics, The boundary-layer regime for convection in a rectangular cavity. 26 (1966) 515-536.

[2] H. Ozoe, K. Fuji, International journal of heat and mass transfer, Long rolls generated by natural convection in an inclined, rectangular enclosure, 26 (1983) 1427-1438.

[3] Z. Y. Zhong, K. T. Yang, J. R. Lloyd, Numerical Methods in Heat Transfer, Variable-property Natural convection in tilted Enclosures with Thermal Radiation, 3 (1985).

[4] Y. Yang, Natural convective flow and heat transfer in vertical and inclined glazing cavities. University of Massachusetts Amherst report, Mechanical and Industrial Engineering (2003).

[5] N. K. Groenhout, M. Behnia, G. L. Morrison, Experimental Thermal and Fluid Science, Experimental measurement of heat loss in an advanced solar collector, 26 (2002) 131-137.

[6] D. Henderson, H. Junaidi, T. Muneer, T. Grassie, J. Currie, Renewable and sustainable Energy Reviews, Experimental and CFD investigation of an ICSSWH at various inclinations, 11 (2005) 1087-1116.

[7] F. P. Incropera, D. P. Dewitt, (2001). Fundamentals of Heat and Mass Transfer, Fifth Edition. John Wiley and Sons, New York.

[8] J. M.S. Cruz, G. P. Hammond, A. J.P. S Reis, Applied Energy, Thermal performance of a trapezoidalshaped solar collector/energy store, 73 (2002) 195-212.

[9] T. Muneer, S. Maubleu, M. Asif, Renewable and sustainable Energy Reviews, Prospects of solar water heating for textile industry in Pakistan, 10 (2004) 1-23.

[10] D. Ashley, Introduction to CFD (2006). [online] Available from: http://personalpages. manchester. ac. uk/staff/david. d.apsley/lectures/comphydr/introcfd. pdf#search=%22In troduction%20to%20CFD%22 [Accessed on 16-09-06]

[11] J. Klems, P. Haves, Z. Zhai, Q. Chen, Strategies for coupling energy simulation and computational fluid dynamics programs, Berkeley, USA (2006). [online] Available from:

http://www. osti. gov/bridge/servlets/purl/860211D9HuG3/860211 .PDF#search=%22principle%20of%20C FD%22 [Accessed on 13-02-06]

[12] S. W. Churchill, H. Ozoe, H. Sayama, International Journal Heat and Mass Transfer, Natural convection in an inclined square channel, 17-3 (1974) 401-406.

On the basis of the time-separated working, two distinct models have been elaborated for swimming pool — and kindergarten operations (Figs 2-3), which are shown next in details. The problem was carried out by the MATLAB® and, for some particular calculations, by the MAPLE® software packages.

|

|

In Figs 2-3 the following notations were applied:

Ig — global irradiance on collectors’ plane, W/m2;

Ta — outside, ambient temperature, °C;

W — wind velocity, m/s;

Ф — relative humidity of air;

m c — mass flow in collector loop, kg/s;

Vp — volumetric flow in swimming pool loop, m3/s;

Tm — temperature of control room, ambience of the heat exchangers, °C; Th, p,m — swimming pool heat exchanger, pool side, inlet temperature, °C;

V& — domestic hot water load, m3/s;

To — temperature of control room, ambience of solar storage, °C;

Tt — water supply inlet temperature, °C;

Tsout — outlet temperature from the storage to the gas heater, °C.

Both models can be run with inputs either determined by meteorological models or available from measurements. According to the notations above, in the case of calculations by meteorological models, one should give only the number of day (1-365) from that the model can determine the inputs required by the model of the system. These calculations, noted by the block “Meteorological models” are carried out by relations in relevant literatures [1], [2]. As a result the outputs noted at the end of the block are realized. The database underlying for the taken over meteorological models as well as the term clear day occuring later in this paper can be found in [3].

The block “Measured data” represents the case when the inputs for the system are from measurements. The input of the block is a particular date that monitored data, which constituting outputs for the block, are available for. It should be noted that the measurements of the system pertains to the ordinary control method used generally in practice, which operates with fixed switching on and off temperature differences between the collector fluid and the actual consumer.

The outputs of the so far discussed blocks constitute the inputs of the blocks “Model of the system for swimming pool operation” and “Model of the system for kindergarten operation”, from which we get the calculated temperatures of the swimming pool water and the solar storage as outputs. In case the inputs of the blocks are measured data, it makes sense to compare the calculated swimming pool temperature with the measured input temperature at the swimming pool side of the pool heat exchanger noted by T11 in Fig. 1. The temperature of the swimming pool is directly not monitored.

The model assumes well mixed, with homogeneous temperature, swimming pool.

Likewise it makes sense to compare the calculated solar storage temperature with the measured output temperature from the storage noted by T10 as there is no temperature measurement inside. The model assumes well mixed, with homogeneous temperature, solar storage.

Temperatures T11 and T10 also make part as system inputs on Fig. 2 and Fig. 3, but certainly are not considered in calculations. They only play comparison purposes with the relevant calculated results. Dashed lines are used on figures to note that, as outputs of the model of the system, arbitrary variables, either monitored or determined by calculations at any part of the model, can be queried.

According to the inner structure of the models, the working of the different parts can be looked through in the following manner, mentioning the references playing as sources for the sub-models. The main system units have been located in distinct sub-models, that can be used independently too. Such parts are the collector sub-model [4], the heat exchanger sub-model [5] both in swimming pool and in kindergarten operations, the swimming pool sub-model [6], [7] and the solar storage sub-model [5]. There is also a particular sub-model for determining the cooling and delaying effects of the “long” pipelines in the system applying the adequate one dimensional partial differential equation [8] relating to energy conservation law. There is actually a 75 meters distance along pipeline between the kindergarten heat exchanger and the solar storage tank.

Several relations discussed in reference [2] have played as a source for several details.

The model elaborated by the aforementioned description determines and takes into account all energy components influencing the performance and efficiency of the solar heating system. At the swimming pool side these are the evaporation-, radiation-, convection-, conduction-, recovery water heat losses, the active, gained by the solar installation, and passive solar gains. The irradiated energy on collectors’ plane, utilized energy by the collectors, transferred energy in the heat exchanger and relevant losses as well as solar energy directly used up by the consumers are also determined. The possibility of auxiliary heating according to the all-time consumptions is also involved in the model. Because of limits in volume the specification of the describing equations, which can be found in the referenced literatures, is omitted now.

2. Results and discussions

In this paragraph the validation of the model is discussed along with the special effect of the evaporation heat loss coefficient at the swimming pool.

The energy sources considered in this project were solar, aeolic, and biomass. These renewable energy sources are abundant in the region, adequate for the distributed generation and impact as much for the quality of life as well as for generation of income and jobs in the region, particularly in the case of castor bean plant with the inclusion of family agriculture in the prodution chain of biodiesel.

The development of SIGA-SOL methodology includes diverse stages that can be schematically seen in Fig. 6 where the fluxogram of development of the GIS planning module is shown. The great stages of development of the module for planning the inclusion of renewable energies can be seen from left to right and represent:

■ Collection of raw data on renewable energy resources, infrastructures, economic and social information, demographies, indices of non-electrification, aptitude for determined cultures, installed renewable energy systems, existing wells, among others;

■ Elaboration of a standardized geographic data bank, that is, referenced and uniform data;

■ Elaboration of data bank with dimensioning of PV energy systems and for pumping water; estimation of electricity generated by sugar cane bagasse; estimation of electricity generated by wind and climatic aptitude for biomass cultures;

■ Creation of a system that permits cross information according to rules dictated by geographics, techniques, social or administrative restrictions. The crossing is a geographic filtering that permits an answer to a given investigation of the user and

■ Finally the study of the best locals is done for inclusion of a determined renewable energy technology in accordance with some criteria pre-established by the user.

|

The management module has the same structure as the planning module, however, it has different geographic data bases and results. The geographic data bank in this case contains detailed information on the PV systems installed by PRODEEM, phases I to V and emergent phase (pumping) whose fields are defined in the Technical Report on Revitalization of Energy Systems and Information on the Availability of Energy Sources. The results permit the identification of types of equipment, kinds of benefits, installation phase, ill functioning (fault), distance to the nearest maintenance center, among others.

A modified evacuated solar tube has been proposed, with a first development on the materials, fluid dynamic and design. It will not be enough to obtain the desired results in term of global efficiency, but it’s the first step to improve its characteristics. The model has been built in 2D-axial symmetry geometry, based on the real object realized for tests. The average velocity of the fluid is 0,0556 m/s, and water has been selected as a vector fluid. The solar tube has been modelled using k-s turbulence model, one of the most used for industrial applications. The model introduces two additional transport equation and two dependent variables: the turbulence kinetic energy, ke, and the dissipation rate of turbulence energy, sT. The k-s model [7] is described by the transport equation:

![]() (12)

(12)

It is possible to derive an equation for sT and all terms that do not have an equivalent term in the ke equation are discarded. It results:

In which CEi, Cs2, Cke and o£T are turbulence model constants, respectively equal to 1.44, 1.92, 1.0, 1.3. г]т is the turbulent viscosity (Pa-s) and U is the average velocity field (m/s).

|

The model constants are determined from experimental data. Some different models have been built, in order to verify different geometries within the same conditions applied in the real case model: fluid vector selection (water), the same inlet velocity, 0,0556 m/s, the same size of the model used (2-10-1 m). In order to have a higher turbulence effect it has been designed a pipe in which the fluid enters in the central part and exit through an annulus area. In the annulus area it have been designed a series of tabulators. Two models have been developed, in one model the turbulators are in the internal part of the tube (see Figure 4), in the second case they are in the external part, directly on the glass internal surface, in the opposite side of the cermet deposition (see Figure 5 and Figure 6).

Figure 4. Evacuated solar tube: 2D-Axial symmetry model. Internal turbulators.

|

Figure 6. Evacuated solar tube: 2D-Axial symmetry model. External tabulators on copper tube. Evident is the tabulation effect near the borosilicate glass tube. In the left it is evident the whole 2D-Axial symmetry model simulated. |

The turbulation has an important effect, as it can be seen in the graph below. It increases the convective heat transfer lowering the thermal gradient between the cermet layer and the vector fluid. In the following figure it can be seen the difference between the turbulators on the internal tube and the turbulators on the external tube in the case of borosilicate glass or copper material used for the tube itself.

|

0 12 3 4

Position from Cermet Layer, mm Figure 7. Temperature distribution for the different modelled evacuated solar tubes at the vector fluid output. The tube has got a thickness of 1,5 mm, visible mainly from the Tube 1 temperature gradient. |

In the real model the temperature gradient is 19,2 K. In the different simulations it has been lowered until a value of 1, 06 K in the case of a copper tube below the cermet deposition and 2,97 K using a standard borosilicate glass. The reduction of the thermal resistance and of the temperature gradient has the effect to increase the thermal efficiency of the solar collector, mainly in the region between 273 and 373 K in temperature difference between the solar collector and the ambient, as reported in the figure 1, in the upper region "other losses". The estimated improvement in the global efficiency of the collector derived from the previous results can be about 10%.

The main objective of this paper is to show a proposal for a possible improvement to heat transfer losses on evacuated solar collectors to reach a higher efficiency and to meet the requirements to apply a thermodynamic cycle (i. e. Rankine or Stirling cycles). The use of a Stirling engine, for example, may allow the production of electrical power, together with a thermal power recovery from the same system. To reach such result it is necessary to obtain on the vector fluid higher temperatures, mainly above 473 K. At the moment part of the modelled work has been transposed to lab scale and the first measures have been taken. A full series of trials will follow, with a single tube and with a complete solar collector. The next step will be a deeper investigation through experimental activity. Another important aspect will be the optimization of the optics and of the concentrators. Thus, a research on cermet materials is starting with the objective to improve the efficiencies mainly in the temperature range of interest (473^573 K) for the proposed technology development. Our research will move on the development of nanostructured layers with possible different and improved optical performance in terms of thermal stability, emissivity (mainly above 473 K), and transmittance [3], [4].

The authors are indebted with Kloben (Turco Group S. r.l.) for partially funding this research. The cooperation between Kloben and Fondazione Bruno Kessler has produced four patents pending for international extension.

[1] D. Y. Goswami, S. Vijayaraghavan, S. Lu, G. Tamm, New and emerging developments in solar energy, Solar Energy 76 (2004) 33-43.

[2] L. J. Shah, S. Furbo, Theoretical flow investigation of an all glass evacuated tubular collector, Solar Energy 81 (2007) 822-828.

[3] L. J. Shah, S. Furbo, Vertical evacuated tubular-collectors utilizing solar radiation from all directions, Applied Energy 78 (2004) 371-395.

[4] F. P. Incropera, D. P. DeWitt, Fundamentals of Heat and Mass transfer, 4th ed., John Wiley & Sons LTD, 1996.

[5] P. Oelhafen, A. Schuler, Nanostructured materials for solar energy conversion, Solar Energy 79 (2005) 110-121.

[6] D. Xinkang et al., Microstructure and spectral selectivity of Mo-Al2O3 solar selective absorbing coatings after annealing, Thin Solid Films (2007), doi:10.1016/j. tsf.2007.07.193.

[7] B. Mohammadi, o. Pironneau, Analysis of the K-Epsilon Turbulence Model, John Wiley & Sons LTD, 1994.