Как выбрать гостиницу для кошек

14 декабря, 2021

|

|

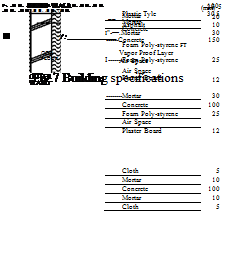

A simulation model was a detached house. The plan and elevation views are shown in Fig. 6, the building material specifications in Fig.7, and the schedules of various items in Fig.8. The areas for the analysis were Sapporo(43°4’N, 141°21’E), a cold weather region, Tokyo(35°39’N, 139°41’E) and Osaka(34°41’N, 135°30’E), mild weather regions, and Naha(26°12’N, 127°41’E), a hot weather region. The Standard year of expanded AMeDAS weather data 1981-2000 for each area were used.

|

|

|

WE G1 |

|

WW |

|

ІШ0 |

|

innn |

|

1 5 000 |

|

PLAN

SOUTH ELEVATION |

|

EAST ELEVATION |

Natural room temperature and thermal load when the roof is assumed to be autonomous perspiration (autonomous perspiration mode) were compared with those of non-perspiration mode in summer (Sapporo: from July to August, Tokyo and Osaka: June — September, Naha: May — October). The specific sense temperature of the autonomous perspiration mode was set to five kinds (20, 25, 30, 35 and 40 °С). The air-conditioning case (living & dining room, master room and children room are air — conditioned) shown in Fig.8 and un-air-conditioning case (all rooms un-air-conditioned, i. e., natural room temperature calculation case) were both investigated, and in the former case, the room set temperature and humidity were 27°C, 60% during the cooling period. The areal supply water temperature, changed monthly, was assumed to be equal to the monthly average outdoor air temperature in each area.

The air channel is modelled through a stationary one-dimensional volume, with a linearly temperature variation in the vertical direction. Three different working conditions are possible: q”ef = q”g1f; q”ef ^ q”g1f, and adiabatic condition q”ef; q”g1f = 0. Concerning the nature of the flow, three situations are considered: natural, forced (wind or mechanical fan) and mixed convection. In the natural convection situation, two flow regimes exist: the laminar and the turbulent. Besides, a distinction between thin and wide channels is considered. The governing equation, once integrated, can be expressed as:

mcp (Tf — Tf, i) = {q’”f + qgif ]Wy (6)

Where: Tf is the air average temperature at height y (°K); y is the height (m); Tf is the average temperature at the inlet (°K); m is the mass flow rate (Kg/s); Wis the width of the fa? ade (m) and q”ef and q”g1f are the convective heat sources. They are calculated as: qf = q”cond — q"”g and

q"g1f = q"g1 cond + q””g1. Assuming the Newton law of cooling for the heat convection sources, making

some arrangements and integrating along the fa? ade height we can obtain the average wall and outlet temperatures.

The flow-rate is obtained by equating the sum of the pressure differences which drive the flow (wind and buoyancy) with that of those opposing it (hydraulic and friction losses):

A • ( + ) + B h+J — 1 [(fappR”m )• H ++X Kh ] = 0 (i0)

![]()

![]() + H 2SG”

+ H 2SG”

where: H =————- is the dimensionless height; A = —

2R”Dh b P”

is the wind-induced term; S is the stratitification coefficient; Kh are the inlet and outlet hydraulic losses; fapp is the apparent friction factor and Dh is the hydraulic diameter (m). The term fappR” is likewise depending on H+, which means that an iterative process must be set up. The expression of fappR” depends on the boundary conditions, on the flow nature, and on the flow situation: in laminar free convection and symmetric uniform heat fluxes, the correlations of Kaka? [9] were validated through CFD simulations. In the case of adiabatic wall boundary conditions, the correlations of Kaka? [9] are also accepted if G”D < 105. In the case of asymmetric conditions, the new correlation

(see equation 3) is used. In turbulent free convection, the term fappRe is no longer linear dependent on H. For this situation only correlations for forced turbulent fully developed flow exist [6]. In mixed flow convection, a composition of the previous correlations will be used. The pressure difference term (APw) is calculated using a dynamical pressure expression dependent of the pressure coefficients.

Once all the terms are determined, a Newton Raphson method is used to solve Equation 10.

A. Roos1* , A. Werner2 and A. Rolandsson3

1 The Angstrom Laboratory, Uppsala University, Box 534, 751 21 Uppsala, Sweden

2 AF-consult, Fleminggatan 7, PO Box8133, SE-104 20 Stockholm, Sweden

3 Pilkington Floatglas AB, Box 530, SE-301 80 Halmstad, Sweden

* Corresponding Author, arne. roos@angstrom. uu. se

External condensation on high performance windows is a recent problem occurring during clear nights when the window U-value is very low. The phenomenon begins to appear with U-values below around 1.5 W/m2K. In this paper we show experimental results indicating that using an external low-e coating on a window the formation of condensation can be delayed or even avoided. In another experiment it was shown that a hydrophilic coating on the external surface reduces the light distortion caused by the condensation and also that the formed condensation tends to evaporate faster than from a window without the hydrophilic coating.

Keywords: external condensation, high performance windows, hydrophilic, low emissivity

1. Introduction

In heating dominated climates a low U-value is required to reduce heat losses through windows, preferably in combination with a high solar heat gain. A fundamental drawback with very low U — values is that they can lead to the formation of water condensation on the external surface of the window in certain weather conditions. The condensation forms small drops of water on the glass surface, which cause refraction of transmitted light to the extent that the view through the window is sometimes completely obstructed. This effect has led to a surprisingly high resistance against energy efficient windows in several countries. Many customers have been given the advice to avoid the very best windows in order to avoid “the problems with external condensation”. Yet the problem is not really a very big one since the phenomenon only occurs during special weather conditions with high humidity, a clear sky and no wind. The condensation is predominantly formed during periods of falling outside temperature (evening, night, early morning) so that the dew point of the outside air is only a degree or so below ambient temperature. This means that the surface temperature of the glass pane falls below the dew point due to radiative cooling and the low heat losses from the inside are insufficient to heat the surface above this dew point. Condensation is thus formed in the same way as on the windows on a car parked in the street during the night. On building windows it mainly happens during autumn and spring and on average over the year only a few days per month, depending on the nature of the surroundings and on the actual U-value of the window [1-3].

Modern low-e coating technology has led to this situation with window U-values being well below 1 W/m2K for the best windows [4]. In this paper we show that modern glass coating technology can also be utilized to avoid the problem without sacrificing the high performance of the glazing.

Two concepts have been tested. Since the surface temperature of the glass pane falls below the dew point of the surrounding air due to radiative cooling, one obvious solution to the problem is to use a low-emissivity surface on the external surface. This keeps the surface temperature of the glass surface above the dew point and condensation is never formed [5].

Another concept that has been experimentally studied is to use a hydrophilic coating on the external glass surface. Such a coating has almost the same emissivity as uncoated glass (around 0.84) and does not influence the surface temperature of the glass pane. Thus condensation is formed at the same weather conditions as for uncoated glass. However, due to the hydrophilic nature of the surface the wetting angle of the water drops is very low and the condensation tends to form a sheet of water rather than individual drops on the surface. This means that the optical distortion caused by light refraction in the water drops is reduced, and the external view through the window is only marginally distorted [6].

2. External condensation

|

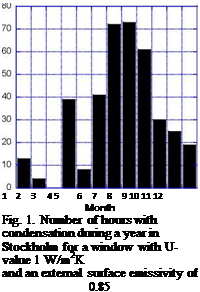

In northern Europe external condensation predominately happens during the spring and autumn, and when the centre-of-glass U-value is below around 1.5 W/m2K. It becomes more frequent as the U-value decreases. Even with a very low U-value the total number of hours with external condensation is small, and it is only a problem during those hours when somebody is present. A number of attempts have been made to simulate the occurrence of external condensation. This can be done by calculating the temperature of the external surface hour by hour and count how many hours this temperature is below the dew point. Such calculations can lead to a frequency diagram as shown in Fig. 1 [7]. The calculations indicate the number of hours condensation can be formed, however, and there is an uncertainty since the time it takes for the condensation to evaporate is more difficult to calculate. Once condensation has been formed it can stay for a long time even when no more humidity is condensed on the surface. In Fig. 1 there are more hours of condensation in the summer than in spring and autumn. A more detailed analysis of exactly when condensation occurs also reveal that condensation is mostly formed during the very early hours in the morning before sun rise. Summer condensation is therefore usually not noted since it is gone by 7 am.

3. Experimental

3.1. Condensation detection test box

In the investigation a number of different surfaces were tested in a specially designed test box [8]. The tested surfaces were tilted 45 degrees towards the sky to optimize the growth of condensation, and the box was heated internally to simulate the heat flow through the window in a real situation. The condensation was detected by a light deflection system. A beam of light was going through the tested glass pane to a detector inside the box. When condensation was formed the light beam was scattered and the detected signal decreased. During the experiment the temperatures of the tested panes were measured using thermocouples attached on the internal test surfaces. The external and internal air temperatures were also measured.

The Centre Product Design for Sustainable Development (PDSD) develops research and advanced human education on specific issues focusing on solar energy conversion and environment, [11]. The Centre hosts solar-thermal and solar PV systems, [12], installed on the roofs that are used for research on increasing the efficiency of the solar energy conversion and adapting to the mountain clime, Fig. 1:

The Solar House, under construction, was designing considering the use of the solar-thermal system

(1) and heating pump (8) for heating.

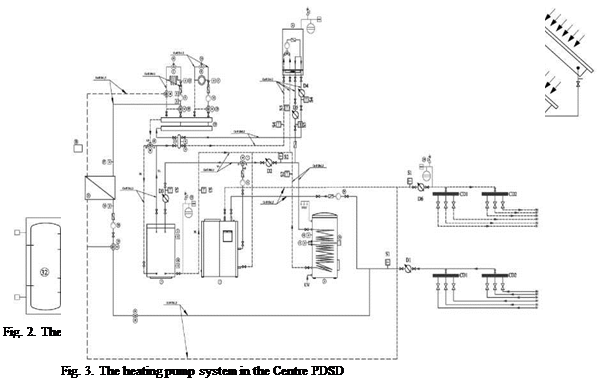

The solar thermal system (S/T) will provide domestic hot water during summer and heating agent in the radiant flooring, fully meeting the heating demands during autumn and spring and partially, during winter, Fig. 2. It comprises of six flat plate collectors and three vacuum tube collectors, two heat storage tanks (1000L), a bi-valent boiler for domestic hot water (400L), and the auxiliary safety parts.

The heating pump (HP) provides supplementary heating during winter and cooling during summer,

Fig. 3. It has a 600m long pipe circuit, a collector/distributor, the soil-water pump (10kW) a buffer heat

|

accumulator (400L), a bi-valent boiler (300L), and auxiliary parts. As back-up source a condensation heater, using methane gas is installed. The solar-thermal system and the heating pump are designed as independent systems, with a monitoring and data acquisition line installed for each.

The Solar House has, beside the energy provided by the above-mentioned systems, a specific design considering the passive use of the solar radiation. The egg-shape of the house, Fig. 4, favours controlled warm and cold air circuit supporting the heating/cooling loads during the extreme temperatures in summer and, respectively, in winter. The transparent walls (double glazing fenestration) have specific role in lighting and in thermal insulation and are designed with blinds automate operated during warm periods. The radiant flooring acts as a thermal mass, storing the heat resulted as the greenhouse effect during sunny winter days.

Fig. 4. The Solar House

The 10 kWp PV array in the Centre is grid-connected but an energy balance based on the power used in the Solar House and the power fed in the grid can complete the global picture of the energy consumption in the House.

A comparative analysis of summer meteorological data measured in the Geneva region over the 1990-2005 period yields following results [1], as illustrated in fig. 1:

• As well in urban as in rural areas, classified summer temperatures are very similar from one year to another, never exceeding 35°C. As a notable exception, 2003 however characterizes by around fifteen days with peak temperatures exceeding this threshold.

• Night temperature always drops lower in rural than in urban areas, whereas day temperatures do rise to similar peaks.

• To the contrary of the dry temperature, the wet bulb temperature of 2003 remains close to that of other years. This indicates a stable potential of evaporative cooling, to the contrary of direct night cooling and other techniques examined further down.

2. Building

Representative of the administrative building stock, the architectural typology is that of a low depth building, with 20 m2 / 50 m3 offices distributed on both sides of a broad central corridor. In terms of simulation, this typology results in a thermal model made up of three zones: two offices, on opposite facades and separated by the central corridor, with lateral boundary conditions given by identical interior climate (neighbor offices).

The parameters that govern the thermal behavior of the building are as follows:

• Thermal mass is mainly determined by 28 cm thick slabs, in heavy option (full concrete: 510 kJ/K. m2) or medium option (combined wood structure with concrete filling: 350 kJ/K. m2). In both cases, separation walls between offices add an additional 170 kJ/K. m2 (relative to ground surface).

• Thermal insulation is any of low 1980’s quality (6 cm, double glazing windows), or high quality as given by the Swiss Minergie standard (20 cm, triple glazing insulating windows).

• Solar access is determined by an E-W orientation on a low 5° horizon, along with a 50% window-to-wall ratio. Efficient external solar protection (overall g-value: 13% with 1980 windows, 7% with Minergie windows) are activated when direct radiation on the facade exceeds 10 W/m2.

• Internal gains are 10, 20 or 35 W/m2 (during occupation: 8-18 h).

The optical transmittance and transmission coefficients for these films given in table 1 show that these parameters increased with increasing wavelength from 300 nm up to about 800 nm. From this point, these parameters were found to decrease with wavelength. Tables 1, 2 and figs. 1-3 also show that the parameters decreased with increasing thickness of films. For example, maximum visible transmission coefficient for Snl2 film with a thickness of 5.2×10-9m is 9.6x106m-1, that for a thickness of 11.7×10-9m is 8.8×106 m-1 while for a thickness of 16.7×10-9m; it is 9.0x 106 m-1. The values of transmission coefficients for Snl2 films of thickness 11.7×10-9is from 2.7 to 4.7 x o6 m-1 in the UV and from 6.5 to 4.7 x 106m-1 in the NIR. The values of the transmission coefficients for MnBr2 and FeCl2 follow this pattern. High values of radiation transmission coefficients in any region indicate high transmittance (transparency), whereas low values indicate opacity of the films in that region. Thus, the high values of these parameter in the VIS region indicates that the films are highly transparent to visible radiation while the low values of the parameters in the UV and NIR show that the films are opaque in these regions.

The integration of solar thermal collector into building facade brings several essential advantages in comparison with solar collectors mounted separately from building envelope (in front of envelope or on supporting structures above the roof). Facade collectors have been investigated in number of research projects [1-3] to reveal advantageous synergy effects of facade integration. Additionally to the basic function of solar collectors, facade collector serves also as protecting shield against atmospheric effects (weather protection) and improves the thermal properties of the building with respect to passive solar gains in winter season. Furthermore, integration of collectors into building facades leads to aesthetically and visually more attractive solution compared with collector fields placed on flat roofs (most of residential buildings in urban housing estates), which create industrial appearance of the buildings. Facade solar collector can be either thermally coupled with envelope (direct integration) or thermally separated by means of ventilated air gap (indirect integration). Advantage of facade direct integration comes in higher thermal efficiency of solar collector due lower front heat loss through glazing (vertical air gap results in lower Nusselt number than inclined) and due to lower back and edge loss (building insulation layers) at normal incidence of solar radiation.

|

Behaviour of solar systems with facade collectors has been analysed through usability of solar gains to cover energy demands for hot water and space heating systems and interaction of facade solar collectors with building indoor environment (heat gains through envelope in winter, interior overheating in summer) in detail [4-6]. For climatic conditions in central Europe, the maximum annual irradiation is received with 45° sloped surfaces oriented to the south. In the case of facade collectors with a vertical slope, the reduction in the annual irradiation sum is around 30 %. Fig. 1 shows the annual profile of average daily solar irradiation for roof (45°) and facade (90°) collector based on the test reference year for Prague. The comparison shows a large difference between the summer peak and winter season values for the case of roof solar collector and a relatively uniform profile for the facade collector which corresponds closely to the heat demand profile (approx. constant with a decrease in the summer season, in the case of DHW system). Thus, solar DHW systems with facade collectors require approximately 25 % higher collector area to achieve solar fraction 50 — 60 % compared to optimally sloped collectors (45°). Required faqade collector area becomes equal to roof installations in the case of oversized DHW systems with higher solar

fraction (above 65 %) but with much shorter stagnation periods due lower portion of nonutilisable energy gains in summer [4]. For solar combisystems (DHW and space heating) the situation is different. Due to relatively uniform irradiation profiles, facade collectors provide the same yearly energy gains in comparison with standard roof installations but with radically reduced frequency and level of stagnation conditions [5, 6] for usual design parameters.

An alternative to using a storage vessel to maximise the use of solar heat is to match the heat demand to the availability of solar heat. This can be achieved by allowing appliances like the dish washer or the washing machine to start operating only when sufficient solar heat is available. Instead of setting the start of the washing program, the latest allowable time of stop of the program can be set.

Simulations are carried out for the base case, which includes a 3 m2 vacuum collector and a 150 l vessel. Different DHW and hot fill patterns are compared, including the one described in chapter 3.2.3, a pattern with heating demand only during the day time, one with heating demand only during the night time and one where the daily heating demand for DHW and hot fill is ‘smeared out’ over 24 hrs.

The results show a difference in primary energy savings between the different patterns in the order of 1%. This small figure is due to the fact that even a rather small 150 l storage vessel is an efficient way to match the heating demand to the availability of solar heat. The results suggest that rather than implementing complicated control devices, that may result in delays and therefore annoyance on the part of the occupant, the use of a storage vessel is a better way to maximise the use of solar heat.

In the beginning of the questionnaire, LESO-SEB occupants were asked to state their agreement with the statement “In general, the lighting in my office is comfortable”. Average agreement with this statement was found to be 87%, a comparably high percentage: Average agreement with the same statement in the US had previously been found to be only 70% [9]. 78% of the 23 study participants think that the lighting within their ADS-equipped office is better than the lighting in other offices where they have previously worked. 22% judge the lighting comparable to their former offices. None of them feel that the lighting at the LESO-SEB is worse compared to the lighting in previous offices.

J. Arce1,2,3, J. Xaman2, G. Alvarez2, M. J. Jimenez3, J. D. Guzman3 and M. R. Heras3

1 CIE-UNAM, Centro de Investigacion en Energia, Priv. Xochicalco S/N Col. Centro, Temixco, Morelos, CP 62580, Mexico

2 CENIDET-DGEST-SEP, Department of Mechanical Engineering, Centro Nacional de Investigacion y Desarrollo Tecnologico, Prol. Av. Palmira S/N. Col. Palmira.

Cuernavaca, Morelos, CP. 62490, Mexico

3 CIEMAT, Department of Energy, Energy Efficiency in Buildings Unit, CIEMAT,

Madrid, E-28040, Spain.

Corresponding Author, j earl@cie. unam. mx

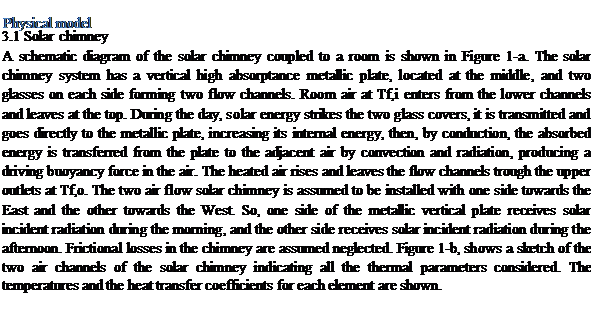

A theoretical study on a solar chimney for diurnal use with double air flow is performed.

The chimney’s dimensions are; 2.0 m height, 1.0 m width, and 0.15 m depth for both flow channels. The principal element is a metallic plate between double glass cover, one side toward the East and the other one toward the West. Glazing is used in order to decrease the radiation and convection losses to the environment. Two air inputs at the bottom and two air outlets at the top are used. For some established environmental conditions, the energy conservation equations are resolved for each element of the chimney in order to calculate the temperature distribution, the efficiency of the system and the mass flow rate. The model was verified with the results reported in the literature for a reduced problem of a single flow chimney, obtaining very good agreement. For an irradiance of 500 W/m2, a maximum mass flow rate of 0.06 kg/s was calculated for the double air flow chimney.

Keywords: Solar chimney, natural convection, ventilation

1. Introduction

Nowadays, natural ventilation in the design of buildings is one of the important requirements, mainly because contamination or energy savings. Ventilation is the movement of air from the exterior to the interior. It is very important to replace the inner air in any building in order to enhance the air quality and the thermal performance. In the last three decades, the study of ventilation has been increasing among the scientific community. Earlier, there existed very few studies of natural ventilation systems in the literature. This fact may be due to the use of conventional systems, such as air conditioning systems and air heating systems to create artificial environments. However, it is well known that oil is rapidly decreased; besides air pollution is another issue that needs to pay attention. Passive systems such solar chimney may contribute to decrease the use of conventional fuels and also improve the environment of buildings. A solar chimney is defined as a kind of long ventilated heated cavity that should be installed in buildings in sunny places. Small and real scales models have been studied [1, 2-6]. However, the performance of solar chimneys is not completely understood.

|

|||

|

|||

|

|

||

|

|||

|

|||

|

|||

|

|||

|