Как выбрать гостиницу для кошек

14 декабря, 2021

A. Roos1* , A. Werner2 and A. Rolandsson3

1 The Angstrom Laboratory, Uppsala University, Box 534, 751 21 Uppsala, Sweden

2 AF-consult, Fleminggatan 7, PO Box8133, SE-104 20 Stockholm, Sweden

3 Pilkington Floatglas AB, Box 530, SE-301 80 Halmstad, Sweden

* Corresponding Author, arne. roos@angstrom. uu. se

External condensation on high performance windows is a recent problem occurring during clear nights when the window U-value is very low. The phenomenon begins to appear with U-values below around 1.5 W/m2K. In this paper we show experimental results indicating that using an external low-e coating on a window the formation of condensation can be delayed or even avoided. In another experiment it was shown that a hydrophilic coating on the external surface reduces the light distortion caused by the condensation and also that the formed condensation tends to evaporate faster than from a window without the hydrophilic coating.

Keywords: external condensation, high performance windows, hydrophilic, low emissivity

1. Introduction

In heating dominated climates a low U-value is required to reduce heat losses through windows, preferably in combination with a high solar heat gain. A fundamental drawback with very low U — values is that they can lead to the formation of water condensation on the external surface of the window in certain weather conditions. The condensation forms small drops of water on the glass surface, which cause refraction of transmitted light to the extent that the view through the window is sometimes completely obstructed. This effect has led to a surprisingly high resistance against energy efficient windows in several countries. Many customers have been given the advice to avoid the very best windows in order to avoid “the problems with external condensation”. Yet the problem is not really a very big one since the phenomenon only occurs during special weather conditions with high humidity, a clear sky and no wind. The condensation is predominantly formed during periods of falling outside temperature (evening, night, early morning) so that the dew point of the outside air is only a degree or so below ambient temperature. This means that the surface temperature of the glass pane falls below the dew point due to radiative cooling and the low heat losses from the inside are insufficient to heat the surface above this dew point. Condensation is thus formed in the same way as on the windows on a car parked in the street during the night. On building windows it mainly happens during autumn and spring and on average over the year only a few days per month, depending on the nature of the surroundings and on the actual U-value of the window [1-3].

Modern low-e coating technology has led to this situation with window U-values being well below 1 W/m2K for the best windows [4]. In this paper we show that modern glass coating technology can also be utilized to avoid the problem without sacrificing the high performance of the glazing.

Two concepts have been tested. Since the surface temperature of the glass pane falls below the dew point of the surrounding air due to radiative cooling, one obvious solution to the problem is to use a low-emissivity surface on the external surface. This keeps the surface temperature of the glass surface above the dew point and condensation is never formed [5].

Another concept that has been experimentally studied is to use a hydrophilic coating on the external glass surface. Such a coating has almost the same emissivity as uncoated glass (around 0.84) and does not influence the surface temperature of the glass pane. Thus condensation is formed at the same weather conditions as for uncoated glass. However, due to the hydrophilic nature of the surface the wetting angle of the water drops is very low and the condensation tends to form a sheet of water rather than individual drops on the surface. This means that the optical distortion caused by light refraction in the water drops is reduced, and the external view through the window is only marginally distorted [6].

2. External condensation

|

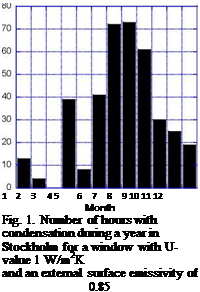

In northern Europe external condensation predominately happens during the spring and autumn, and when the centre-of-glass U-value is below around 1.5 W/m2K. It becomes more frequent as the U-value decreases. Even with a very low U-value the total number of hours with external condensation is small, and it is only a problem during those hours when somebody is present. A number of attempts have been made to simulate the occurrence of external condensation. This can be done by calculating the temperature of the external surface hour by hour and count how many hours this temperature is below the dew point. Such calculations can lead to a frequency diagram as shown in Fig. 1 [7]. The calculations indicate the number of hours condensation can be formed, however, and there is an uncertainty since the time it takes for the condensation to evaporate is more difficult to calculate. Once condensation has been formed it can stay for a long time even when no more humidity is condensed on the surface. In Fig. 1 there are more hours of condensation in the summer than in spring and autumn. A more detailed analysis of exactly when condensation occurs also reveal that condensation is mostly formed during the very early hours in the morning before sun rise. Summer condensation is therefore usually not noted since it is gone by 7 am.

3. Experimental

3.1. Condensation detection test box

In the investigation a number of different surfaces were tested in a specially designed test box [8]. The tested surfaces were tilted 45 degrees towards the sky to optimize the growth of condensation, and the box was heated internally to simulate the heat flow through the window in a real situation. The condensation was detected by a light deflection system. A beam of light was going through the tested glass pane to a detector inside the box. When condensation was formed the light beam was scattered and the detected signal decreased. During the experiment the temperatures of the tested panes were measured using thermocouples attached on the internal test surfaces. The external and internal air temperatures were also measured.