Как выбрать гостиницу для кошек

14 декабря, 2021

|

|

|

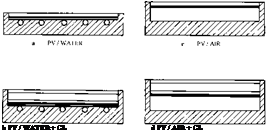

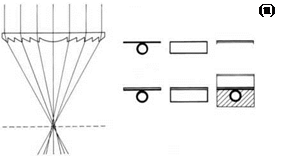

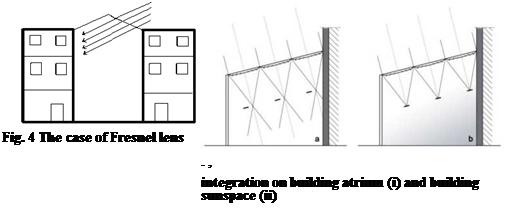

The hybrid Photovoltaic/Thermal (PVT) systems (Fig. 3-i) can be combined with linear Fresnel lenses (Fig. 3-ii) and can be used for space heating and cooling of building interior spaces. The Fresnel lenses with the hybrid PV/T absorbers (FRESNEL/PVT system) aim to maximise the energy conversion from Fresnel lens type solar energy systems, which can be used as transparent material of building atria (Fig. 4-i) or sunspaces (Fig. 4-ii). From the performed laboratory experiments most of the transmitted solar radiation from the lens glazed roof can be absorbed, controlling the illumination of the interior space and providing also electricity and heat to cover several building energy needs. The shading/cooling effect by the suggested system (Fig. 4-ii, b) can adapt about 50% of the needs, only from the heat extraction by the absorber operation, which can be higher if we consider fan or AC operation by the provided electricity from the PVs. In case of using Fresnel lens with 42 cm focal length, the collection of 60%-80% (Fig. 5-i) of the transmitted solar radiation through the transparent cover leaves the rest amount of solar radiation to be distributed in the building space for the illumination needs. Test results showed that a considerable lighting and temperature reduction in the interior space is achieved [22].

Fig. 3 The basic designs of PV/T collectors (i) and the Fresnel lens concept with the absorber types (ii)

|

An alternative system design is the integration of the linear Fresnel lenses on building fa$ade or inclined roof and the absorber to be PV cells of smaller strip width, to receive the peak of the converged to focal line solar rays. In this design, the non-used converged radiation and also the diffuse radiation by the cells can be absorbed by flat or cylindrical elements placed in a small distance from PV strip (Fig. 5-ii). These elements form an air duct with system thermal insulation and the air can circulate through it to achieve building ventilation. In this system the cell material is reduced (lower PV module cost) and all not-used solar radiation by PV cells is absorbed for effective water heating.

The New Norwegian building regulations (TEK07) describe two ways to fulfil the new energy regulations for a building; the Energy measure method and the Energy target method [11].

The target method is based on net specific energy demand per year, the efficiencies of the energy systems are not taken into account. Passive measures that reduce the net cooling demand will contribute to satisfy the energy frame. This puts an extra focus on utilizing passive measures to decrease the total energy use in buildings. The regulations still contain minimum requirements concerning the U-values and air tightness of the building envelope which help to maintain a good insulation standard [11].

1.2. PH

Particularly in the residential sector the passive house standard has become widely used [10]. Although the passive house standard is well defined in residential buildings in Germany there is still no official definition for Nordic countries [3]. Today, it is not clear if the passive house standard can be used as a design guidance for office buildings [14].

2.3. ZNE

There is no definition of a zero net energy building. Torcellini et al. (2006) provided an overview of the various approaches [13]. ‘A net zero-energy building (ZEB) is a residential or commercial building with greatly reduced energy needs through efficiency gains such that the balance of energy needs can be supplied with renewable technologies. ’ Torcellini et al. (2006) used this as a definition but they also indicated that ’ …we lack a common definition, or even a common understanding, of what it means. ’

In this paper, the annual operational energy consumption of a building according to NS 3031:2007 is balanced with annual on-site energy production. It has been used for calculating on-site electricity and heat production without looking into storage and grid connection issues. This

approach does not take into account the daily and seasonal mismatch between demand and supply of energy. Results of an annual net energy balance can thus only be an indicator for energy concepts and cannot be used for detailed energy design.

One of the main decisions in this project was to design a building without air conditioning; it was one of the main challenges in this building design and in this climatic conditions. The main cooling strategies used in summer in this building are; (a) prevention of solar heat gain, (b) night ventilation and (c) ground cooling system.

(a) The building is very well insulated by outside, the windows have external shading devices which permit the user to have a total control of the incoming solar radiation;

|

|

(b)  The building has a system of openings, which allows very easily the cross ventilation and upper openings which facilitate the use of nigh ventilation strategies, very efficient in this type of climatic conditions.

The building has a system of openings, which allows very easily the cross ventilation and upper openings which facilitate the use of nigh ventilation strategies, very efficient in this type of climatic conditions.

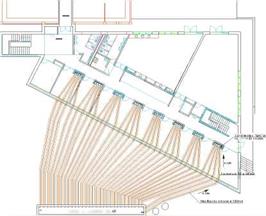

(c) A ground cooling system was built (Figures 7 and 8) and it consist in a set of 32 concrete pipes with 30 cm of diameter, buried at 4,5 m depth, beneath the lower basement (Figure 7). Will allows the air to flow from the inlet, placed at 15 m in front of the building, to inside the building. The air is cooled in these pipes, to a temperature near the ground temperature, and goes directly to the rooms in first and second floor, two pipes per room. The user in each room can control individually the incoming fresh air by opening the apertures or turning on a small fan. This system only affects directly the south part of the building, which is the more problematic in terms of heat. The north part of the building is naturally ventilated and less problematic.

|

Fig. 7.Ground Cooling System. |

1*"

FOSO DE ADMISS4O DE

Fig. 8.Buried pipes for ground cooling.

Two kinds of precast products (a combined precast and a separated precast) made of rock wool as a base material were developed as an improved perspirable roof to strengthen nonflammability. Fig.1 shows the combined precast product (10mm in thickness) and the separated precast product(5mm in thickness). The combined precasting consists of three layers, the arrangement is as follows; nonwoven fabric in the first layer (outside layer) for surface protection, rock wool and thermal bond fiber in the 2nd layer for ultraviolet rays penetration prevention, and thermo-sensitive hydrogel, rock wool and thermal bond fiber in the 3rd layer in three layer structure. (It is called sample (1).) On the other hand, the separated precasting assumes to be a double layer system, which consists of the 1st layer and the 3rd layer of the combined type, eliminating the 2nd layer. (sample (2)) Both products were able to clear the fire test as a nonflammable material by the cone calorimeter examination.

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 1(a) Perspirable roof (Combined precast product) Fig.1(b) Perspirable roof (Separated precast product)

Three TRNSYS types have been programmed to define the fa? ade energy performance: the PV laminate type, the air channel type and the rear glass type. All the types are dynamically coupled by the TRNSYS sequentially solver: the heat conduction heat sources obtained from the first and third types are transferred to the second type as a Newmann boundary condition. Once the heat transfer coefficients, the mass flow rate and the average wall temperatures are obtained within this type, they are returned back to the first and third type. This is an iterative process which converges each time step. The underlying mathematical and physical models are described in the sections bellow.

1.2. Physical model

Air enters the fa? ade at the bottom opening with an average inlet temperature (f ) which is assumed equal to the uniform exterior air temperature (To ). Hot air exits from the top of the chimney at outlet average temperature (f ). The following heat transfer processes simultaneously happens within the fa? ade: solar radiation absorbed by the ^ lid layers, thermal radiation between the back side of the PV laminate and the rear glass front side, thermal radiation between the external layer of the PV laminate and the sky and heat convection between the exterior, the interior and the fa? ade.

The program also includes control algorithms for electrochromic coatings. In these simulations one energy optimization, and three daylighting control strategies were employed. The energy optimization mode, here referred to as “Energy”, sets the window in the dark state when cooling is needed and in the bleached state when heating is needed. This strategy minimizes the energy use, but may not be ideal from a daylighting perspective. The two daylighting controls, here referred to as “Dayl.100-400” and “Dayl.250-400” respectively, set the window in the dark state if the solar radiation exceeds 100 (250) W/m2 and sets it in the bleached state when solar radiation is below 400 W/m2. For radiation levels between the two set points the glazing is regulated to intermediate values proportional to the radiation level. In these simulations the “Dayl.100-400” and “Dayl.250-400” control strategies where used during office hours (7am to 6pm) and for the rest of the time the window was regulated according to the energy optimization control algorithm. A refinement was made to the “Dayl.100-400” control strategy by isolating a lunch hour (12noon to 1pm), during which the window was operated according to the “Energy” control strategy. It is assumed that the user is absent during this time, and therefore not affected by unacceptable lighting conditions. This refined control strategy will be referred to as “Dayl. f0“0”!400 ”.

4. Results and Discussion

Results of the energy simulations are shown in figures 3-6. The simulations were performed for a relatively well insulated building of medium thermal mass and with a balance temperature of 8 degrees Celsius. The control strategies described above where applied to the solid state electrochromic window (SS light/dark), and the two solar control (Soft SC and Abs. SC) windows in table 1 were used as references. Solar energy transmittance and thermal data for the simulated windows are presented in table 2.

|

Table 2. U — and g-values for the three simulated windows.

|

Fig. 3 shows the cooling energy balance per square meter glazed area window oriented towards the south in Stockholm, Brussels, and Rome. The negative values indicate the need to remove energy from the building, i. e. cooling, in order to maintain the indoor temperature set point. As expected

the overall cooling need is much higher in Rome than in Stockholm and Brussels. It can be noted that all three electrochromic control strategies performed better than the static solar control coatings, and that the best cooling energy performance was achieved with the electrochromic “Energy” control strategy. However, this may result in unacceptable visual comfort levels for the user. It is also likely that low daylight levels will increase the electric lighting energy consumption, which is not accounted for here. The difference between the absorbing and soft solar control coating can be contributed to the lower g-value of the absorbing coating. The U-value of the low-e coating is significantly better, but when studying cooling load the g-value is of greater importance.

|

Fig. 4 Heating energy balance for a one square

meter window positioned on a south facing facade

in Stockholm, Brussels, and Rome.

The heating energy balance per square meter glazed area positioned on a south facing faqade in Stockholm, Brussels, and Rome is shown in Fig. 4. The “Energy” control of the electrochromic window and the soft solar control window outperform all other windows in terms of heating energy consumption. However, the high visible transmittances of these coatings, combined with the absence of other solar shading strategies and a south facing faqade, may result in visually uncomfortable conditions. From a heating perspective the “Dayl.250-400” is a slightly better control strategy than the “Dayl. i00-400”, but as previously mentioned the opposite is true for the cooling energy balance. The net result is that the “Dayl.100-400” control strategy is better in all locations except Stockholm, where the two control strategies perform equally well. In mixed climates with both cooling and heating needs it could be meaningful to use different control strategies during different parts of the year. For example, if the “Dayl.250-400” control strategy was used from November through April, and the “Dayl.100-400” for the rest of the year an additional 13 kWh/year, could be saved for each square meter window area on a south facing faqade in Stockholm. The absorbing solar control window is outperformed by all other windows due to its high U-value and low g-value.

Fig. 6 shows the total energy balance for the “Dayl.100-400” and the refined “Dayl. ” control strategy versus eight faqade orientations of a building located in Stockholm. Utilizing the “Dayl. f0“0K;400 ” control strategy, which employs energy efficient switching algorithms between 12noon and 1pm, can save up to 32 kWh/year for a south facing window. Considering the position

of the sun during this time it is not surprising that the biggest savings are achieved for south and southwest facing facades. In Stockholm the most significant energy reduction is due to increased utilization of passive heating during the winter. Similar results where obtained for Brussels and Rome, but the energy savings were to a greater extent attributed to reduced cooling need.

|

I. Visa*, A. Duta, S. Fota, C. Nastac

Transilvania University of Brasov, Centre: Product Design for Sustainable Development, Eroilor 29,

500036 Brasov, Romania

* Corresponding Author, visaion@unitbv. ro

The concept of low energy building is mostly addressed to as an answer to the requirements for clean energy and environment protection. The use of renewable energy systems, implemented in the design of different residential applications must be correlated with the availability of the input energy and requires, in certain climatic conditions, supplementary co-generation systems. The integrated use of solar energy, for solar-thermal and solar PV conversion, along with a heating pump system, can offer an integrated solution for inner space and water heating/cooling and, partially, for the power consumption. The design of such a system must be adapted to the beneficiaries’ demands but, must follow a suitable, flexible algorithm. The paper presents the results obtained in the design of a combined system based on solar-thermal and heating pump system associated with a PV array, implemented in the building of the research department Product Design for Sustainable Development, in the Transilvania University of Brasov, Romania.

Keywords: Low energy building, photovoltaic, solar-thermal, heating pump

1. Introduction

The climatic changes due to the greenhouse gases (GHG) represent a major concern for our sustainable future. The eight Millennium Development Goals are the core of the meeting agenda in the next UN Session from 25 September 2008, when the world leaders are expected to renew their commitment and to set out concrete plans and actions, by 2015, for further sustainable development, including environmental sustainability. The concept answering to these needs involves sustainable energy: energy efficiency, energy saving and renewable energy systems, jointly approached both in economy sectors and at social/societal level.

European Community had clearly moved towards action for climate change mitigation, through reduction of GHG, sustainable development, security of supply and the development of a knowledge based economy, by developing the Directive on the promotion of the use of energy from renewable energy sources, [1]. The directive, known as 20/20/20 sets a mandatory target of a 20% share of renewable energies in overall Community energy consumption by 2020. The directive actually reformulates the values of the targets previously set for each EU country thus long term plans can already be found, as it is the Dutch Future Energy System, [2] that considers a complex of actions for energy efficiency in industry, CO2 neutral feedstock for transportation, renewable energy and highly

insulated buildings in the built environment. The expected result is an 80% reduction of the GHG emissions (comparing with 1990), till 2050.

The long term strategies require an integrated approach, while resource management becomes a key issue; thus there must be considered the quantification of all the energy and materials needed in the consumption, both for construction/product development (embodied energy and materials) and for usage; exergetic life-cycle assessment models have been developed for approximating the overall needs in industrial but mainly in residential applications, [3].

Concluding, a reduction of the GHG emissions arising from the built environment can be achieved by the development of new building materials (with low thermal transfer coefficient) and the adoption of the building integrated renewable energy conversion technologies.

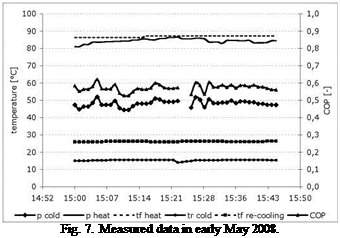

The analysis of the data for the cold production in summer 2007 has shown significant shortcomings according the absorption chiller itself. Especially in the second half of the year the machine has reached neither the capacity nor the efficiency written in the technical documents of the manufacturer. Therefore, the manufacturer carried out a maintenance of the machine in early May 2008.

Afterwards, a series of measurements were conducted. The intention was to test whether the technical characteristics would be fulfilled better. Therefore the system was partly controlled manually to provide constant conditions for the absorption chiller.

To reproduce the characteristic curve of the machine different temperatures for the hot and cold — water circuit were set up. Each condition was hold for 45 minutes to reach steady-state conditions.

|

The temperatures in all three circuits of the machine — heat circuit, cold-water circuit and recooling circuit — where measured with three different sensors. The data recorded by the data acquisition system during the fifth series of the measurements are shown as an example in figure 7.

The required capacity is reached in some of the five series, but the COP does not reach the specification in any of them. The output deficit, relative to the desired/planned COP, is between 23 and 30 %.

For the performance of the machine this means a significant additional consumption of heat and electric power. The primary energy coefficient increases from 0.26 to 0.38 (+46 %) and the emission of carbon dioxide per produced kilowatt hour cold rises from 39 to 63 g/kWh (+62 %).

Because of the not satisfying results the absorption chiller was optimized again in early June 2008 and another measurement was done, showing that the required capacity of 40 kW is slightly exceeded with 41.7 kW. The COP averages 0.64. It falls below the specified COP by 2 %. Hence, the performance now meets the demands. To ensure that this is a stable situation another check is planned in autumn 2008.

5. Conclusions

In 2007, the absorption chiller used in the Museum Ritter yielded no advantage with reference to either primary energy or CO2 emissions compared to a good conventional compression chiller. The main reason was, besides the poor thermal COP, the high consumption of electric energy.

But even with an ideal COP of 0.7 the energy consumption worsens the primary energy factor from 0.28 to 0.44 and the specific CO2 emissions from 17 to 51 gCO2/kWhcold. For a constant performance with a high COP the operating parameters have to be controlled more precisely as for a compression chiller. By increasing the re-cooling temperature by 1 K, the absorption chiller looses between 10 to 20 % efficiency whereas the reduction of the actuation temperature from 86° C to 82° C lessens the efficiency by 20 %. A decrease of the cold-water inlet temperature by 1 K induces a loss of efficiency of about 10 %.

A compression chiller however can be run over a broad range with constant efficiency (e. g. from 10 to 21° C cold-water inlet temperature and 20 to 45° C re-cooling-water inlet temperature), although with changing COP. Therefore, the heat delivery and re-cooling must ensure preferably constant conditions. This is difficult due to the complicated hydraulics of the technical systems in the Ritter Museum.

Due to the actuation by heat, the higher demand on re-cooling and the lower re-cooling temperature an absorption chiller induces a higher consumption of auxiliary energy. That includes electricity for the pumps and fans used for heat generation and re-cooling. Also the water conditioning of the back feed of the cooling tower has to be taken into account. In the Museum for example six pumps are installed for this purpose. Therefore it is important to plan these auxiliary energy consumers in a very energy saving way. This includes short circuit pipes for heating and recooling, generously calculated cross section diameters to achieve small pressure losses and high efficient pumps. The electric auxiliary energy consumption is usually not accounted in the usual technical documentations.

Absorption chillers are not operated in full load all the time. Therefore a standard test series with different operation modes would be useful to compare units of different manufactures. This could result in more reliable specification for planning and comparison of absorption chillers.

Overall, the results show that the further development and improvement of small and medium sized absorption chillers is necessary. Also it is evident, that the monitoring of these systems is very important in order to detect performance failures in real (transient) operating modes which are normally not tested in test facilities..

The monitoring of the Ritter Museum will be continued in 2008. Hence, the optimization will be verified.

Acknowledgement

This work was funded by the German Ministry of Economy and Technology (BMWi) within the research programme "Energy optimized buildings (EnOB)"; reference number 0329084D. The authors also like to thank the project coordinator (PTJ) and the Museum Titter staff for their support.

From the available roof area, the total suitable PV area can be estimated. Two scenarios are considered: a PV Fraction=30% and a PV Fraction=20%. Where PV fraction is the percentage of occupation of suitable roof area by PV.

A fraction superior to 30% will be difficult to implement. The 20% option is taken as a conservative scenario in order to account for difficulties in the installation due to the wide type of devices that can be located on the roofs (such as the air handling units required by the new regulation [2,3,4]). The total area of PV (for the 172 schools) will range between 115 000 m2 and 172 000 m2, for a PV fraction of 20% and 30% respectively.

Transparent and semi transparent thin films of some metal halides, were deposited on glass slides using a chemical solution bath containing either a metallic sulphate, nitrate or higher valance halide; an alkali halide and an alkali hydroxide as the complexing agent (ligand). The films grown by this method are iron halides, tin halides, and manganese halides.

The spectral transmittance/absorbance curve of the films in the UV-VIS-NIR region were obtained using a Pye Unicam spectro photometer sp 100 and 650. These spectral curves were used to obtain the absorbance and percentage transmittance values. Also, the absorption coefficient and transmission coefficient were computed from the values of the absorbance and transmittance. The other parameters were then derived from the absorption coefficient using relation between the absorption coefficient and other optical parameters [3, 63]. For example, the relation between the absorption coefficient and the extinction coefficient and refractive index are given [3, 63] as:

|

k = and |

a k/4n |

(1) |

|

n = |

k/x |

(2), |

|

For films whose k and n could not be obtain from literature. |

Where k is the extinction coefficient, a is the absorption coefficient which is obtained from the absorbance curve, n is the refractive index, к is the wave length of radiation which is obtained from the curve as well, and x is the thickness of the film which was obtained by the gravimetric (weight deferential) method and confirmed with a talystep instrument.

X — ray diffraction and analysis showed that the films produced were good quality polycrystalline films of Sn, Mn and Fe chlorides, bromides and iodides; and Ag2S,,when compared with standard values from ASTM X-ray diffraction files [3].