Как выбрать гостиницу для кошек

14 декабря, 2021

The analysis of the data for the cold production in summer 2007 has shown significant shortcomings according the absorption chiller itself. Especially in the second half of the year the machine has reached neither the capacity nor the efficiency written in the technical documents of the manufacturer. Therefore, the manufacturer carried out a maintenance of the machine in early May 2008.

Afterwards, a series of measurements were conducted. The intention was to test whether the technical characteristics would be fulfilled better. Therefore the system was partly controlled manually to provide constant conditions for the absorption chiller.

To reproduce the characteristic curve of the machine different temperatures for the hot and cold — water circuit were set up. Each condition was hold for 45 minutes to reach steady-state conditions.

|

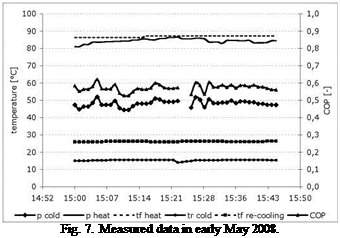

The temperatures in all three circuits of the machine — heat circuit, cold-water circuit and recooling circuit — where measured with three different sensors. The data recorded by the data acquisition system during the fifth series of the measurements are shown as an example in figure 7.

The required capacity is reached in some of the five series, but the COP does not reach the specification in any of them. The output deficit, relative to the desired/planned COP, is between 23 and 30 %.

For the performance of the machine this means a significant additional consumption of heat and electric power. The primary energy coefficient increases from 0.26 to 0.38 (+46 %) and the emission of carbon dioxide per produced kilowatt hour cold rises from 39 to 63 g/kWh (+62 %).

Because of the not satisfying results the absorption chiller was optimized again in early June 2008 and another measurement was done, showing that the required capacity of 40 kW is slightly exceeded with 41.7 kW. The COP averages 0.64. It falls below the specified COP by 2 %. Hence, the performance now meets the demands. To ensure that this is a stable situation another check is planned in autumn 2008.

5. Conclusions

In 2007, the absorption chiller used in the Museum Ritter yielded no advantage with reference to either primary energy or CO2 emissions compared to a good conventional compression chiller. The main reason was, besides the poor thermal COP, the high consumption of electric energy.

But even with an ideal COP of 0.7 the energy consumption worsens the primary energy factor from 0.28 to 0.44 and the specific CO2 emissions from 17 to 51 gCO2/kWhcold. For a constant performance with a high COP the operating parameters have to be controlled more precisely as for a compression chiller. By increasing the re-cooling temperature by 1 K, the absorption chiller looses between 10 to 20 % efficiency whereas the reduction of the actuation temperature from 86° C to 82° C lessens the efficiency by 20 %. A decrease of the cold-water inlet temperature by 1 K induces a loss of efficiency of about 10 %.

A compression chiller however can be run over a broad range with constant efficiency (e. g. from 10 to 21° C cold-water inlet temperature and 20 to 45° C re-cooling-water inlet temperature), although with changing COP. Therefore, the heat delivery and re-cooling must ensure preferably constant conditions. This is difficult due to the complicated hydraulics of the technical systems in the Ritter Museum.

Due to the actuation by heat, the higher demand on re-cooling and the lower re-cooling temperature an absorption chiller induces a higher consumption of auxiliary energy. That includes electricity for the pumps and fans used for heat generation and re-cooling. Also the water conditioning of the back feed of the cooling tower has to be taken into account. In the Museum for example six pumps are installed for this purpose. Therefore it is important to plan these auxiliary energy consumers in a very energy saving way. This includes short circuit pipes for heating and recooling, generously calculated cross section diameters to achieve small pressure losses and high efficient pumps. The electric auxiliary energy consumption is usually not accounted in the usual technical documentations.

Absorption chillers are not operated in full load all the time. Therefore a standard test series with different operation modes would be useful to compare units of different manufactures. This could result in more reliable specification for planning and comparison of absorption chillers.

Overall, the results show that the further development and improvement of small and medium sized absorption chillers is necessary. Also it is evident, that the monitoring of these systems is very important in order to detect performance failures in real (transient) operating modes which are normally not tested in test facilities..

The monitoring of the Ritter Museum will be continued in 2008. Hence, the optimization will be verified.

Acknowledgement

This work was funded by the German Ministry of Economy and Technology (BMWi) within the research programme "Energy optimized buildings (EnOB)"; reference number 0329084D. The authors also like to thank the project coordinator (PTJ) and the Museum Titter staff for their support.