Как выбрать гостиницу для кошек

14 декабря, 2021

During the project two pilot plants have been investigated by the ISFH. The pilot plant Limburg is measured since September 2006, the pilot plant Klein-Koeris (near Berlin) since November 2007. Due to the short measuring period of the HPS Klein-Koeris, only the results of the plant Limburg are presented in this paper.

The HPS Limburg supplies a 300 m2 single-family house with heat and consists of 14 BHE each with a depth of 17 m, a 16 kW heat pump and 44 m2 roof integrated, unglazed solar collectors produced by the company Rheinzink (QUICK STEP SolarThermie).

The measured monthly mean values in Fig. 2 show a strong seasonal variation. Therefore it is necessary to analyse the total energy fluxes and the performance factor at least on a one year lasting time scale.

![]()

25

25

20

15

![]()

![]() 10

10

5

0

The HP delivers 33.3 MWh/a of heat energy, which covers the demand of the floor heating system (70%) and the domestic hot water system (30%). The annual HPS performance factor (HPF) amounts to 4.0, if the power demands of collector and borehole pump are neglected. With these additional consumers the HPF is 3.5.

The measurements show a 20% higher electric power consumption of the HP compared to the manufacturer information. With the promised efficiency of the HP, the HPS would come up to an annual performance factor of 5.0. The measured collector yield of 545 kWh/m2a covers the annual heat demand on the evaporator side of the HP.

Further results can be derived from the measurements:

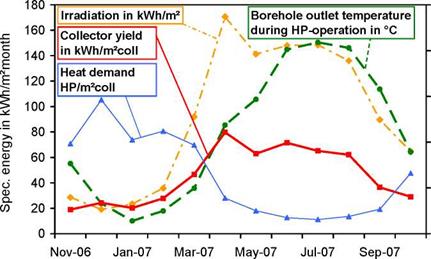

• The unglazed collector charges the borehole during summer. The borehole reaches a maximum monthly mean outlet temperature of 20°C during HP operation.

• A high specific collector yield of 545 kWh/m2a is reached. Due to collector operation during night with convective and condensing gains the collector yield in December is higher than the irradiation.

• The averaged measured outlet temperature of the BHS is 6°C. Typical design temperature of a HPS without solar thermal system amounts to approx. 0°C.

•

|

On summer days with high irradiation a temperature of 20°C to 25°C is reached at the source side of the HP (Fig. 3). In the following night the source side temperature can drop down to 10°C. This high temperature difference in the course of a day emphasizes the need of dynamic simulations to describe the accurate behaviour of HPS.

|

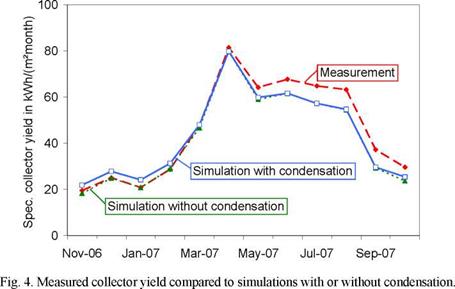

The collector model regarding EN 12975-2 is much more complex for unglazed than for glazed SC. In addition to the irradiance and the ambient temperature the wind velocity and the infrared radiation exchange is needed too. For collector fluid temperatures nearby or even below ambient temperature condensation on surface of unglazed collectors has to be regarded. The literature mentions condensation heat gains amounting to 5% up to 30% of the collector yield. A condensation model was developed [2] and validated by measured data and finally implemented in a TRNSYS collector type for unglazed SC.

Simulations of the Limburg plant show a total share of the condensation gains in the annual collector yield of 4%, maximum daily shares of up to 30% have been observed. During the winter period condensation heat gains reaches highest fractions of the collector yield (average value 14%). Considering condensation the difference in simulated and measured collector yield drops from 8.4% down to 5.3% (Fig. 4). It is assumed, that the residual difference is primarily caused by fundamental problems in measuring the representative wind velocity and ambient temperature over the large area of the unglazed collector array.

2. Simulation Results and Conclusion

The single components and the whole HPS were modelled in TRNSYS and validated using the measured data. A long period of validation is very important, because the operational behaviour of the HPS shows a significant difference between summer and winter.

Subsequent to validation a reference system is built up in TRNSYS and the correlation between annual HPS performance factor (HPF) and the main influencing factors such as collector area, borehole length etc. is investigated. The boundary conditions of the reference system are shown in Tab. 1.

Tab. 1. Boundary conditions of the reference system simulated in TRNSYS

|

Parameter |

Value |

|

Space heat demand |

60 kWh/m2a |

|

Radiator heating |

40°C |

|

Domestic hot water, 4 persons |

170 l/d at 45°C |

|

Heat pump |

7.5 kW thermal |

|

Total heat demand |

11 MWh/a |

|

Collector tilt angle |

45°, azimuth 0° (south) |

|

Weather region |

TRY 7 (Kassel) |

|

Heat conductance of the soil |

2 W/mK |

Fig. 5. shows as simulation results the course of HPF as a function of the borehole length an the collector area. If the power consumption of the collector pump is considered, the HPF is reduced by AHPF = 0.2 (energy class A) and AHPF = 0.4 (energy class D)[1] respectively.

There is not only one target variable for system dimensioning according to Fig. 5. The choice of collector area and borehole length leads to two possible targets: energy saving and investment cost. The standard borehole dimensioning of the reference system based on VDI 4640 leads to a borehole length of 70 m and a simulated HPF of approx. 4.0. Starting from this design point the HPF increases from 4.0 up to 4.4 by adding 20 m2 collector area to the HPS. The same improvement may be achieved by using a borehole depth of 130 m instead of 70 m. The same HPF in the reference system may be achieved, if a short borehole of 35 m will be regenerated by a 10 m2 collector array.

Beside saving of investment cost (BH length) and current cost (electric energy consumption) the usage of collector in HPS enhances the planning certainty of the whole system. The curves of the systems with collector are much more flat than the curves without collector (Fig. 5). Thus extreme supercooling of the BHE caused by improper dimensioning of the system can be prevented by integrating a collector. E. g., a difference in thermal conductivity of the soil of 1 W/mK instead of

2 W/mK decreases the HPF of the reference system from 4.0 down to 3.7. The system with 20 m2 collector area is almost unaffected by this modified thermal conductivity. Similar positive effects of the collector may be stated, if the real heat demand of the building is higher than assumed for the design process.

Borehole length in m

Beside collector area and borehole length additional parameters influence the HPF. Based on a solar assisted HPS (15 m2 collector area, 70 m borehole length) the influence of other parameters on the HPF is investigated (Tab. 2). Changing the heat conductance of the soil or the weather region effects the system by up to AHPF = 0.2. On the side of the heat consumption (supply temperature of the space heating and domestic hot water system) the influence on the HPS is much stronger.

Tab. 2. HPF sensitivity of reference system with collector to changes in system parameters (design point:

collector area 15 m2, borehole length 70 m, HPF = 4.4)

|

Influencing parameter |

Value in ref. system |

Changes |

AHPF |

|

HP-characteristic |

COP 0/35 = 4.6 |

WP 1 COP 0/35 = 4.4 WP 2 COP 0/35 = 4.7 |

-0.3 +0.1 |

|

Heat conductance of the soil |

2 W/mK |

3.6 W/mK 0.4 W/mK |

+0.1 -0.3 |

|

Space heating system |

Radiator 40°C |

Radiator 50°C Floor heating 35°C |

-0.4 +0.2 |

|

Domestic hot water system |

Tstorage = (45+3)°C |

Tstorage = (60+3)°C without DHW |

-0.6 +0.4 |

|

Space heat demand |

60 kWh/m2a |

30 kWh/m2a 100 kWh/m2a |

+0.1 -0.3 |

|

Weather region |

TRY 07 |

TRY 15, TRY 06 |

-0.2 |

It may be summarized, that a HPS without SC is much more sensitive towards modifications on the source side. The solar collector in a HPS minimizes the risk which may be caused by unforeseen high heat extraction or a lower ground heat conductance.

The project „Unglazed Solar Collectors in Heat Pump Systems: System Concept and Dimensioning” is funded by ’’Deutsche Bundesstiftung Umwelt (DBU)” (AZ 21098). The authors gratefully acknowledge this support and carry the full responsibility for the content of this paper.

[1] R. Tepe, M. Ronnelid, B. Perers, (2003). Swedish Solar Systems in Combinations with heat pumps, ISES Solar World Congress, Goteborg.

[2] Eisenmann W., Muller O., Pujiula F., Zienterra G. (2006): Metal Roofs as Unglazed Solar Collectors, Coupled with Heat Pump and Ground Storage: Gains from Condensation, Basics for System Concepts. EuroSun 2006 (6th ISES-Europe Solar Congress, 27.-30.6.2006, Glasgow).