Как выбрать гостиницу для кошек

14 декабря, 2021

|

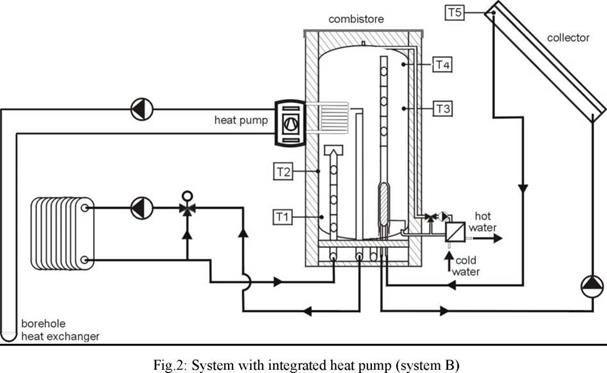

The simulation study is based on a single family house with a living area of 128 m2 located in Wurzburg, Germany. The roof area where the collectors are mounted is facing south with an inclination of 45o. The space heating demand of the building conforms to the current legal energy saving regulations (EnEV) and amounts to 71 kWh/ (m2 a) respectively 9090 kWh/a. The heating control is automatically adjusted to the outside temperature with a maximum flow/return temperature of 35/25°C. The heat demand for hot water amounts to 2945 kWh/a for a daily use of 200 litres at 45°C. The total heat demand (thermal requirement) for hot water preparation and space heating amounts to 12680 kWh/a, assuming heat losses of a conventional hot water store of 645 kWh/a. The flow temperatures for the brine were calculated based on measurements taken at a heat pump system using a borehole heat exchanger and range from 7°C in February to 20°C in July. The heat pump used in system A shows a COP (Coefficient of Performance) of 4,3 according to EN 14511 at 5K temperature difference. In system B a store-integrated heat pump is used which has a different thermal behaviour due to its positioning. This heat pump features a COP as per EN 14511 of 4,1 at 5 K temperature difference. The same flat plate collector with a total aperture area of 12 m2 and performance parameters of a “good” flat plate collector was used for both systems.

Table 1 shows the most important results of the annual simulations carried out for the two systems A and B. In addition the thermal behaviour of a pure heat pump system without solar collectors (system C) was simulated for comparison. This system uses a similar combistore as system A, however with a smaller volume of only 400 litres. For all systems the electric energy consumption for the hydraulic pumps was not taken into consideration for reasons of simplification.

|

Table 1: Results of annual system simulation

|

Table 1 shows that system B requires the lowest amount of heat delivered by the heat pump in order to cover the entire heat demand for hot water preparing and space heating. Furthermore, this system provides the highest “usable hot water volume” and therefore offers the greatest hot water comfort. The positive thermal behaviour of system B is due to the efficient technology for hot water preparation (external heat exchanger combined with a controlled pump) and to the fact that at this system the highest solar energy gains are delivered to the combistore (3685 kWh). Moreover, the combistore of system B shows less heat loss than the combistore of system A. In system A the heat delivered from the collectors to the combistore is lower than in system B due to the control strategy of the collector loop pump: Within regular waiting periods during charging the buffer store it is checked if it is possible to charge the combistore. Nevertheless, system A requires the least electric energy consumption of the heat pump. That is because system A shows the highest COP due to the high temperature level in the buffer store which can occasionally be used as heat source for the heat pump. In comparison to system C (without solar thermal contribution) system A requires approx. 1000 kWh less electricity in order to operate the heat pump. The annual COP increases from 4,0 to 4,4 due to the solar thermal system. As can be expected, system A shows a high collector energy gain due to the additional buffer store.

The investigations have shown that the combination of a solar combisystem with a heat pump is a promising approach for saving primary energy. Due to the use of an additional buffer store in system A the electric energy consumption is less than in system B despite the higher delivered heat of the heat pump. This is due to the higher seasonal performance factor of the heat pump in system A. An

additional saving potential in system B can be utilised if the solar circuit is coupled with the brine circuit by a heat exchanger in order to preheat the return flow of the brine.

In order to compare different combinations of solar thermal systems and heat pumps in an objective way it is essential that standardised test — and evaluation procedures become available.

References:

[1] Kuhl, L., Wendker, K., Fisch, N.: Praxistest von solarunterstutzten Warmepumpen-Heizsystemen; Tagungsband zum 17 Symposium Thermische Solarenergie, Otti-Technologie-Kolleg, Regensburg, Mai 2007; (2) ENV 12977-2: 2001: Thermal solar systems and components — Custom built systems — Part 2: Test Methods, ISBN 0-580-37754-7

[2] EN 14511-3: Air conditioners, liquid chilling packages and heat pumps with electrically driven compressors for space heating and cooling — Part 3: Test methods