Как выбрать гостиницу для кошек

14 декабря, 2021

|

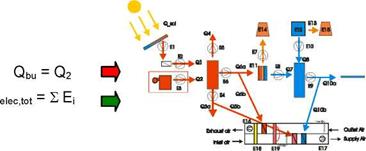

The first level of the procedure permits to acquire basic information on cost and performance (on primary energy level) of the system with a limited number of sensors. Within this level 4 heat flow meters and the electricity counters for the measurement of the electricity consumption of the overall system is required. In Figure 3 the scheme with the measured energy fluxes is shown.

Figure 3. 1st level monitoring scheme including measured inputs and outputs of the solar assisted cooling

system

The primary energy ratio of the solar assisted cooling system can be calculated as shown in (Equation 1:

Where the heat and electricity fluxes are measured while the primary energy conversion factors for heat and electricity from fossil fuels have been set with the following values, being based on European Directives [4], Task 25 and Task 32 [7]:

• seiec = 0.4 (kWh of electricity per kWh of primary energy)

• sfossil = 0.9 (kWh of heat per kWh of primary energy)

• nboiler = 0.95 (boiler efficiency)

In general it has to been stated that the conversion and performance factors given in the present paper are based on literature and discussion agreements but have to be considered only as proposals for calculation and comparison as they depend on different aspects such us country specifications, technology and component size. The Primary Energy Ratio of a reference system (see Figure 2) can be calculated as shown in (Equation 2:

In this equation the heat and electricity fluxes are again the measured values. Within the calculation of the electricity consumption of the reference system the consumption of the pumps of solar circuit loop and of the absorption chiller have to be subtracted according to Figure 2 and as shown in (Equation 3.

![]() Eelec, tot _ ref = Eelec, tot — (E1 + E2 + E6 + E7 + E8 + E10 + E11 + E14 + E18 + E1q)

Eelec, tot _ ref = Eelec, tot — (E1 + E2 + E6 + E7 + E8 + E10 + E11 + E14 + E18 + E1q)

The electricity consumption of the auxiliary E3 has to be corrected as described with (Equation 15, since the auxiliary in the reference has to deliver much more heat. The primary energy conversion factors for heat and electricity from fossil fuels have been listed before, the Seasonal Performance Factor (SPF) of the reference compression chiller has been set to:

• SPFref = 2.8 (compression chiller efficiency of the reference system)

• nboiler, ref = 0.95 (reference boiler efficiency)

From the financial point of view the overall cost per installed cooling capacity can be calculated following

Cost (€) includes the costs of all components shown in Figure 1 minus the appliances deployed in the corresponding conventional reference system (Figure 2) such us back up heating / cooling system and eventually installed cogeneration systems.

2.1. Second level

|

The second step consists within deeper partial monitoring of single parts of the system with an increased number of sensors in respect to the 1st level. In fact within this level 2 heat counters and a pyranometer have to be added to the 4 heat counters and the total electricity counters already present in the 1st level. The monitoring for this level is concentrating mainly on the solar thermal energy management (see Figure 4).

In the following several equations are shown which allow to calculate the amount of solar energy which the solar assisted cooling system is not able to exploit because of different losses such us within the solar collectors, heat exchangers or the storage.

The amount of solar energy that is not exploited because of losses in the solar loop, heat exchangers and collectors is calculated by the (Equation 5 — (Equation 6:

|

Vcott. net _ Q Qsol |

(Equation 5) |

|

^Qsol _ Qsol (1 — Vcoll ) |

(Equation 6) |

|

The amount of thermal energy that is not exploited because of losses in the storage the (Equation 7 — (Equation 8: |

is calculated by |

|

n _ Q3 + Q6 + Q4 иГа*Є Q1+Q2 |

(Equation 7) |

|

Qloss, storage _ (Q1 + Q2) — (Q3 + Q6 + Q4) |

(Equation 8) |

|

Finally, the amount of available solar energy that is not used in the thermal loop of the solar |

|

|

assisted cooling system (Qsolar, unex) is calculated by the (Equation 9 — (Equation 13: |

|

|

SF _ Q (Q, +Q2) |

(Equation 9) |

|

Q* _ SF • Q6 Q3* _… |

(Equation 10) |

|

Q* _ Q* + Q* + Q* |

(Equation 11) |

|

Qo — Q* |

|

|

|

|

|

|

The third level consists in a full system monitoring based on the method of “fractional energy saving” as part of the FSC method which was elaborated in the IEA SHC Task 26 for solar combi systems and extended in the IEA SHC Task 32 for solar heating and cooling systems [7]. This file outlines the energy-flux components required to characterize the performance of solar heating and cooling systems with this method. The FSC method as such is not explained in this document, readers interested in a tutorial on the FSC method are referred to the cited literature [8] [9] [10].

|

|

|

|

|

|

(Equation 14 defines the “fractional solar heating & cooling savings” (f savshc) in terms of:

• energy consumption attributed to auxiliary devices required for the solar heating/cooling system. (numerator)

• energy usage allocated to a reference system with no solar energy-input (denominator)

The crux of the mater is to come up with a practical definition as to define the reference system, having in mind that the only accessible measurement object is the building with the SHC system. The proposed strategy is to derive the electricity consumption of the reference system “Eel, ref” from the SHC system, by adequate modifications in the measurement data analysis, following the below outlined scheme:

• define a maximal equipped SHC system (see Figure 1, labelled “SHC_max system”)

• the appliances deployed in the corresponding conventional reference system are depicted graphically in Figure 2 by skipping all solar assisted equipment from the SHC_max system.

• All thermal and electrical energies of the conventional reference system can be determined from measurements conducted in the SHC_max system using the following assumptions.

• All thermal energies (hot/cold) supplied by solar in the SHC-system are fully substituted by conventional heat/cold production in the reference system.

• Electricity consumption of pumps for DHW+SH and cold supply is equivalent in the SHC — systems and the reference systems.

For the measured solar heating and cooling system (numerator in (Equation 14) the energies according to Figure 1 are as following: The measured boiler energy supplied to the system Qboiler is equal to Q2 and the additional cooling provided from the compression chiller Qc0oiing, m[ssed is equal to Q8. The electricity consumption Eel is the sum of all electricity consumer except the compression chiller: Eel = (£ Ei)-E10-E12-E13-E15.

For the reference system (denominator in (Equation 14) the following calculations have to be done:

For the boiler the ratio of electrical energy to thermal energy is identical in the SHC-system and the reference-system.

Reference storage heat losses according to IEA SHC Task 26 and with reference to ENV 12977-1 (2000):

Qlossref… Reference storage heat losses [kWh/a]

VD.. .Average daily hot water consumption [Liter/day]

TT.. .Set point temperature of the hot water tank [°С], 52.5°C is used for this

in Task 26

Ta. Ambient temp. around the hot water tank [°С], 15°С is used for this in

Task 26

The reference boiler energy supplied to the system therefore is:

Qboiler, ref = Q SHc(Q3) + QsDHcw (Q4) + Qf (Equation 17)

On inspection of Figure 2 the electrical energy consumption in the ref. system sums up to:

Er1f = E DfW, el(E5) + Ef (E4) + Ercrfsupply (E9) + E^”1" + E^ (Equation 18)

|

Eel, boiler ref * aS |

|

= asHc * (QSHc(Q3) + QDHw (Q4) + Qross) |

Where the electrical consumption of the boiler in the reference system is given through:

Fans’ electricity consumption for the conventional ventilation system is calculated based on the measured electricity consumption of the desiccant cooling system (SHC_max,) and corrected by the ratio of theoretical design pressure losses of the conventional ventilation system to the desiccant cooling system (based on datasheet of the DEC system). The electrical consumption of the two fans of the ventilation system can be estimated by:

Б™пРє1 = E™^1 • f (APREF, APdec ) (Equation 20)

Considering that for each fan of the system, the electrical power is given by (with V in [m3/s] and AP in [Pa]):

AP • V

AP • V

EFan =——- W ]

Assuming the same n and flow rates for the fans of the reference and DEC system, the electricity power of the reference system can be calculated as following:

All the AP are known for the DEC system. The AP for the reference Air Handling Unit (AHU) can be estimated considering in the calculation only the components used, assuming that normally the pressure losses of each component of the DEC Air Handling Unit are known from the manufacturer of the AHU.

|

+ (E16 + E17) * f (AP) |

|

|

These calculations result in the definition of the electrical consumption of the reference system in terms of data measured in the SHC-system:

Qcooling, ref = Q cHC= 6acm(Q7) + 6bup(Q8) + Qdec — Q10b 25)

Where QDEC is: Thermal cooling energy delivered from DEC system in the SHC-system in terms of enthalpy difference between ambient air and supply air (latent and sensible heat has to be taken into account!)

The Seasonal Performance Factor SPF for the compression chiller in the reference system can not be known exactly. The following possibilities are proposed:

• SPFmeas measured SPF in the monitored SHC system

• SPFref proposed SPF for a chiller in the reference system: SPFref = 2.8

3. Expected results

The target from the presented monitoring procedure is to have a common base for the monitoring of solar assisted heating and cooling systems, allowing a comparison of the performance of different systems and allowing the elaboration of a learning curve of the following years.