Как выбрать гостиницу для кошек

14 декабря, 2021

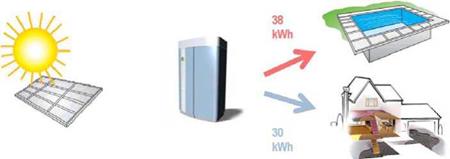

Three external circuits are connected to the Millennium MSS Air Conditioning:

Thermal heat source (e. g. MSS solar collectors)

Air conditioning distribution system for cooling and heating (e. g. radiant floor, fan-coil units)

Heat sink for charging and discharging (e. g. swimming pool, cooling tower, air cooled condenser or geothermal holes)

Millennium Mss Air Conditioning System is a modular absorption machine that differs from the “standard” Lithium Bromide type absorption machines in three main aspects:

It has internal storage in each of the two accumulators. This allows the machine to store chemical energy with a very high density. This energy can subsequently be used both for cooling and heating. It is important to emphasize that this is chemical energy, not thermal energy that is stored.

It works intermittently with two parallel accumulators (Barrel A and Barrel B).

It is designed to use relatively low temperatures and is hence optimized for usage with solar thermal collectors. It also works with a stable temperature inside the accumulators, which in turn allows for an effective use of solar thermal collectors.

Millennium MSS Air conditioning system made up of two “barrels” each consisting of a reactor and condenser/evaporator. The two barrels can operate in parallel.

The water returns from the distribution system at a higher temperature than when it left the condenser / evaporator (we have cooled the building). This heat causes the water in the evaporator to boil and the steam passes down to the reactor, where it condenses, since the reactor is relatively cooler. Steam that condenses into water in the reactor will dilute the LiCl solution. The diluted LiCl solution is then pumped through the filter basket, where it mixes with the salt and regains its saturation. The saturation is needed to continuously provide a temperature difference between the condenser/evaporator and the reactor.

|

|

680 mm 680 mm

Barrel ABarrel B

|

Mode |

Storage Capacity * |

Maximum Output Capacity ** |

Electrical COP[7] |

Thermal Efficiency |

|

Cooling |

60 kWh |

10/20 kW |

77 |

68% |

|

Heating |

76 kWh |

25 kW |

96 |

160% |

|

* Total storage capacity (i. e. including both barrels) |

** Cooling capacity per barrel: 10 kW cooling is the maximum capacity. If both barrels are used in parallel (double mode) the maximum cooling output is 20 kW and the maximum heating output is 25 kW.

|

|

Heating is just cooling in reverse, meaning that the charged energy is extracted as heat by connecting the condenser/evaporator to the heat sink and the reactor to the distribution system. Water returns from the distribution system at a lower temperature than when it left the reactor (we have heated the building). This water boils the water in the condenser/evaporator and steam passes down to the reactor. Steam condenses into water which dilutes the LiCl solution in the reactor. The diluted LiCl solution is pumped through the salt filter basket where it mixes with the salt and regains its saturation. The saturation is needed to continuously provide a temperature difference between the condenser / evaporator and the reactor. During discharging, the heating energy is extracted by connecting the evaporator to the heat sink and the reactor to the distribution system. Under charging, heat can also be extracted by connecting the condenser to the distribution system under charging mode.