Как выбрать гостиницу для кошек

14 декабря, 2021

G. Moldovean 1*, R. Velicu 1, B. Burduhos1

1 Centre of Product Design for Sustainable Development, Transilvania University of Bra§ov, Romania

* Corresponding Author, ghmoldovean@unitbv. ro

Abstract

In order to improve the energy efficiency of PV or thermal collectors (panels), two possibilities are available: better materials and design for the solar energy absorber and the use of solar tracking systems. The paper presents the results of the embodiment design process of the main rotational axes of an experimental equatorial solar tracking system, with two rotational axis: a horizontal fixed axis and an inclined mobile axis. The system is one of ten different tracking systems for PV individual panels implemented, this year, in the campus of the Transilvania University of Bra§ov, Romania. It has been developed in order to research the optimization of the mechanical system of trackers as a meaning of improving the costs and energy efficiency of the system. There have been considered the loading cases depending on the functional positions of the tracking system (positions corresponding to minimum and maximum rotational angles), considering different distributions of wind pressure. Final constructive solutions, elements of preliminary design and conclusions on loads and loading cases involved in optimal embodiment design are presented.

Keywords: equatorial tracker, design, linear actuator, load

1.  Introduction

Introduction

The main advantage of using a tracking system is an increased amount of solar energy converted [1]. As disadvantages, it comes with its specific construction costs and also exploitation costs. An optimal design is mainly improving a tracking system by diminishing the costs of building and exploitation.

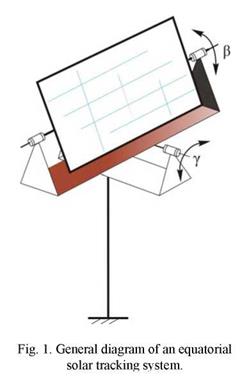

In order to perform a comparison between different solutions of tracking system, in the frame of a Project developed at Transilvania University of Bra§ov, a platform with 10 different tracking systems was developed. This paper is referring to an equatorial tracking system [2] (fig. 1). It has two rotational axes: a horizontal fixed axis (setting the у orientation angle) and an inclined mobile axis (setting the P orientation angle).

Rotation around the horizontal axis must be performed at an interval of few days (seasonal) and rotation around the vertical axis must be performed during each day, for a precise daily solar tracking. In order to perform both two movements the system is using linear actuators.

This paper is presenting a methodology of determining the loads involved in preliminary strength calculus of the elements of the tracking system and also some conclusions on the loading cases and their involvement in the specific loading of elements. The loading cases depend on the functional positions of the tracking system and also the loads caused by own masses, wind etc. (given by the specific of the region).