Как выбрать гостиницу для кошек

14 декабря, 2021

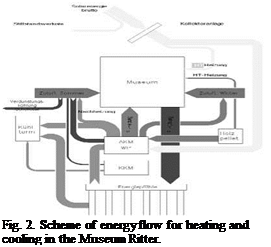

The indoor climate requirements in the exhibition rooms are very high due to the conservation of the art objects. Temperature and relative humidity are only allowed to change in a very small

|

margin (20 — 22 C, 50 — 55 %). Therefore it is necessary to treat the supply air in summer (dehumidification) as well as in winter (humidification). This requires a large amount of energy which should be reduced within this project.

During winter a contact humidifier humidifies the incoming air. The energy demand for vaporization is extracted from the air itself. It is not provided by means of electric energy as in a steam humidifier. The air is heated to approximately 30° C so that it can be supplied to the rooms at about 22° C. A rotating air-to-air heat and humidity exchanger with a heat recovery coefficient of 80 % and a humidity recovery coefficient of 50 % is used for the heat and humidity recovery during winter time. In summer the air is de-humidified by cooling the air to the dew point (8 to 9° C) followed by re-heating to 16 to 18° C by waste heat from the cooling system.

To supply the required cold-water temperatures (6 to 8° C) a chiller is needed. The use of environmental cold extracted from the ground — like it is used for heat removal by ceiling-panel cooling — for the de-humidification process is not possible. In summer, a great part of the air (app. 70 %) is recirculated to reduce the de-humidification volume. The proportion of external air is controlled by CO2-sensors located in the exhibition rooms.

|

The main component to supply cooling and heating is an absorption chiller that is used as a heat pump in winter. It uses low level heat from the soil around 73 foundation piles, connected by a circulating water supply, in winter and is driven by heat from 47 CPC evacuated tube collectors with a total output of 100 kW in summer. If the output from the collector field is insufficient, a wood pellet combustion unit with four boilers and a total output of 128 kW drives the absorption chiller. For each unit of heat from the boilers the heat pump produces 1.7 units of usable heat. 40% of the heat in the heat pump operation mode comes from the soil.

In summer, medium temperature cold (15-18° C) is sourced directly from the foundation piles. A total of 65% of the overall cooling requirement can be gained from the ground. The absorption chiller provides the cold needed for the air conditioning. The solar collector field produces about 80 % of the required heat for the absorption chiller. For peak load and backup a common compression chiller is used.

3. Monitoring

The building is monitored intensely since October 2006 within the research program EnOB (see www. enob. info). A total of 500 data points is recorded continuously. The results are transmitted via ISDN to the Building Science Group at the University of Karlsruhe where the analysis, the calculation of characteristic values and the comparison with the planned performance is done. It is also possible to use information, gained from the evaluation of the data, for optimizing the building performance. The following values are quantified:

• energy flux (heat, cold, electricity)

• temperatures in the technical systems (HVAC)

• temperatures inside the rooms

• humidity inside the rooms

• flow rate of the ventilation

• position of valves

• runtime and speed of pumps

• switching status (on/off)

• consumption of pellets

• solar radiation

The data can be used for example to calculate the COP of the absorption chiller or the efficiency of the ventilation system. The compliance of temperature and humidity values with the requirements is also monitored. Global characteristics, like energy and primary energy consumption per square meter, serve as a base to classify the building.