Как выбрать гостиницу для кошек

14 декабря, 2021

The SWH had been installed on the rooftop for 14 years. This was an indirect system, which consisted of two flat-plate solar collectors and a hot water storage tank with an inbuilt heat exchanger, as shown in Figure 2. This system configuration represents the majority of domestic SWH systems installed in the Maltese islands.

|

Preliminary inspection of the SWH system identified a number of shortcomings in the layout and operation of the equipment. These were typical defects which were identified in a number of systems during an earlier study of installed SWH systems in Malta [5] . The main defects were as follows:

• The solar collectors were not optimally aligned. Orientation was 32° degrees East of true South;

• The pipe that supplied hot water from the SWH to the washing machine had no insulation;

• The solar tank was showing signs of deterioration and there was evidence of some water leakage;

• The electrical back-up heater of the SWH was left switched on all the time, with its thermostat set at 78 °C. This implied that the water in the solar storage tank was continuously being kept at a high temperature; even when not required, leading to higher heat losses and higher electricity consumption. Moreover, the high setting would reduce the effectiveness of solar energy absorption during the day thus reducing efficiency [6] ;

• The solar system was under-designed as it supplied hot water to 2 bathrooms, a Jacuzzi, the kitchen and a large washing machine. The washing machine alone consumed 130 litres per wash — part of which was invariably hot water.

• It was noted that no routine maintenance was carried out on the solar system (change of sacrificial anode, cleaning of tank, etc.)

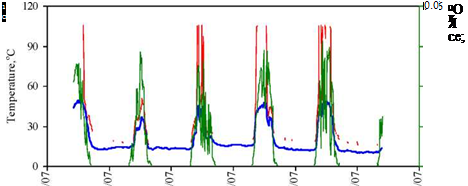

Monitoring of salient parameters of the SWH system was also carried out, such as inlet and outlet solar panel temperatures and horizontal solar radiation. The results of these measurements are shown in Figure 3. The outlet panel temperature was higher than the inlet temperature as would be expected. Moreover, the hot water temperature was in phase with the solar radiation levels, which was also to be expected for a well-functioning solar panel. Thermographs of the SWH were also taken and the collectors exhibited higher temperatures in the upper portions of the risers and in the top header [3] .

|

Fig. 3. Plot showing panel inlet and outlet temperatures, ambient temperature and solar radiation.

|

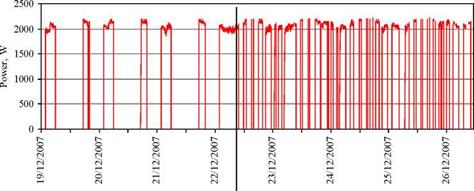

A measure to rectify part of the SWH operational issues was the installation of a timer switch of appropriate power rating to control the electrical backup heater. The timer was tested between 19 and 27 December 2007. This timer was set to switch on early morning and late afternoon. Operating the electrical backup heater in the morning was requested as the homeowners were used to washing clothes early morning rather than later in the day. The latter practice would have been preferred, as the water would have absorbed sufficient solar energy rather than being heated by the electrical backup element. The effect of installing a timer to control the electrical backup heater is illustrated in Figure 4, between 19 and 22 December. Thereafter, the homeowners reverted to thermostat control of the electrical booster, since they had guests for the festive season and they were concerned that hot water might be insufficient. When the timer was in control, the average daily electrical consumption of the back-up heater was 11.43 kWh, but when the thermostat was in control, without the timer, the consumption increased to 17.12 kWh/day. Therefore, the introduction of the timer had saved one-third of the electrical consumption of the electrical backup heater, or 12.37% of the total electricity bill of the house over the full monitoring period.

Fig. 4. Effects of timer control on the electrical backup heater in the SWH storage tank.

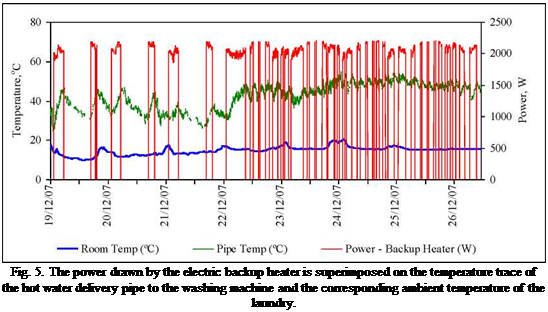

Another test was carried out whereby the surface temperature of the pipe delivering hot water to the washing machine was measured together with the laundry / pantry ambient temperature. Figure 5 shows the results together with the power consumed by the SWH electrical backup heater superimposed. Whenever the electric booster was switched on, it heated the water in the solar storage tank, as well as the water in the hot water delivery pipe to the washing machine, which was over 25 metres long and un-insulated. Given that the temperature gradient between the pipe and the ambient was large, heat losses were inevitable.

|

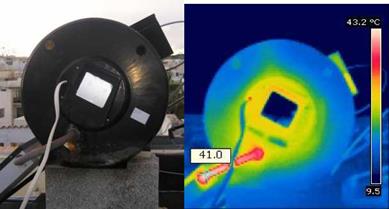

Figures 6a and 6b show one end of the solar water storage tank, where the electric backup heater is located. The rectangle sitting centrally on the plastic cover is a highly reflective specifications label. Heat loss in the vicinity of the electrical backup heater is evident as this part of the tank does not usually have insulation. The un-insulated pipe show a high temperature of 41 °C, while the ambient temperature was 17 °C — a source of heat losses as well.

Figs. 6a & 6b. End view of the SWH storage tank showing the cable feeding the electric backup heater housed

under a plastic cover.