Как выбрать гостиницу для кошек

14 декабря, 2021

The preliminary experimental evaluation involved building and instrumenting an ISAHP system in a laboratory setting, based on the recommendations of component sizing given by Freeman [4].

The solar collector in Figure 1 was replaced with an auxiliary heater in order to perform controlled experiments. Quasi steady-state tests were run at range of constant input temperatures with all variables constant except for the natural convection flow rate. The natural convection flow rate varied throughout the duration of the test while the tank temperature increased. The preliminary results indicated that the original computer model over-predicted the actual COP of the system.

This discrepancy was determined to be due to an over-prediction of the heat exchanger effectiveness values for both the condenser and evaporator. After correcting the heat exchanger effectiveness values in the simulation, the results for power consumption and COP matched to within 3.0 % of each other for the 10oC test.

![]() The dimensioning method presented leads to a solar heating system with a comparably small collector area of 8.9 m2 and a storage device capacity of 0.67 m3; assuming a 60 kWh/m2 single family house located in Zurich with a hot water consumption of 3000 kWh/a. In Table 1 the optimal system configuration for these assumptions (called the base case) are summarised. To find the dimensioning parameters leading to the best cost/benefit ratio a number of simulation runs are necessary. The results of these runs — sorted by primary energy savings and

The dimensioning method presented leads to a solar heating system with a comparably small collector area of 8.9 m2 and a storage device capacity of 0.67 m3; assuming a 60 kWh/m2 single family house located in Zurich with a hot water consumption of 3000 kWh/a. In Table 1 the optimal system configuration for these assumptions (called the base case) are summarised. To find the dimensioning parameters leading to the best cost/benefit ratio a number of simulation runs are necessary. The results of these runs — sorted by primary energy savings and

additional cost — are shown in Figure 2. Each dot in the chart represents a system with a different set of collector area and storage device capacity, leading to specific primary energy savings and additional cost. The quotient of these terms is the cost/benefit ratio which can be understood as the slope of a line through the origin meeting the respective point. The dimensions leading to the smallest gradient, which is also the tangent to a polynomial derived from all points, are the optimal dimensions (cf. [2]).

R. Velicu1*, G. Moldovean1, V. Popa1

1 Centre of Product Design for Sustainable Development, Transilvania University of Bra§ov, Romania

* Corresponding Author, rvelicu@unitbv. ro

As a meaning for efficiency improvement of conversion of solar radiation to other types of energy, solar tracking systems are used. The paper presents the results of the embodiment design process of the main rotational axes of an experimental solar tracking system. The tracking system is azimuthal, with two rotational axis: a vertical fixed axis and a horizontal mobile axis. The system is one of ten different tracking systems for PV individual panels implemented, this year, in the campus of the Transilvania University of Bra§ov, Romania. It has been developed in order to research the optimization of the mechanical system of trackers as a meaning of improving the costs and energy efficiency of the system. There have been considered the loading cases depending on the functional positions of the tracking system (positions corresponding to minimum and maximum rotational angles), considering different distributions of wind pressure. Final constructive solutions, elements of preliminary design and conclusions on loads and loading cases involved in optimal embodiment design are presented.

Keywords: tracker, design,

In order to improve the energy efficiency of fixed PV or thermal collectors (panels), two possibilities are available [1]. The first option is to use materials with better solar absorbent properties and the second is to orientate the panels towards the sun, method which is called “Tracking”. As the first possibility is quite expensive and new materials take more time to be developed, the second option can be reliable and costs less. An optimal design is mainly improving a tracking system by diminishing the costs of building and exploitation.

In order to improve the energy efficiency of fixed PV or thermal collectors (panels), two possibilities are available [1]. The first option is to use materials with better solar absorbent properties and the second is to orientate the panels towards the sun, method which is called “Tracking”. As the first possibility is quite expensive and new materials take more time to be developed, the second option can be reliable and costs less. An optimal design is mainly improving a tracking system by diminishing the costs of building and exploitation.

In order to perform a comparison between different solutions of tracking system, in the frame of a Project developed at Transilvania University of Bra§ov, a platform with 10 different tracking systems was developed.

This paper is referring to an azimuthal tracking system [2]

(fig. 1). It has two rotational axes: a vertical fixed axis (setting the у orientation angle) and a horizontal mobile axis (setting the a orientation angle). The system is using linear actuators in order to perform both two movements.

A proper design must consider the loading cases depending on the functional positions of the tracking system (positions corresponding to minimum, medium and maximum rotational angles on the two main axes) and also the loads caused by own masses, wind, snow etc. (given by the specific of the region). This paper is presenting a methodology of determining the loads involved in preliminary strength calculus of the elements of the tracking system and also some conclusions on the loading cases and their involvement in the specific loading of elements. Some elements of detailed design of the system are also presented.

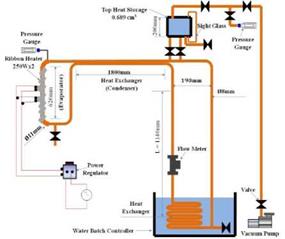

A model of the top heat thermosyphon proposed in the present study is shown in Fig.1(a), called IMT model. The system equipped with a small reservoir of water at the end of the condenser as shown in the figure. The condenser located on the top of the system is consisted of two tubes soldered together. The flow of the mixture of the liquid and vapor in the upper tube is cooled by the lower tube in which the liquid from the cooler flows so that the vapor in the upper tube is condensed. When the volume of the vapor is increased, the total volume of the vapor and the liquid expands. It is aimed to have reservoir for storing the extra liquid at the top. The loop tubes are made from chopper. The inside and outside diameters of loop tubes are 8mm and 9.5mm, respectively, except the tubes of evaporator which have inside and outside diameters of 11mm and 12.7mm, respectively. The length of the evaporator is 620mm. The length of tube of the condenser is 1800mm. The length of the coil dipped in the cooler or water batch controller as heat exchanger is 1200mm. The length between the center of the evaporator and the center of the cooler is 1140mm. The heat input of evaporator is supplied by two ribbon heaters wich consume 250W for one heater. The power of two ribbon heaters are varied by resistors from 0 to 500W. The dimension of thickness, width, and lenght are 1mm, 20mm, and 500mm, respectively.

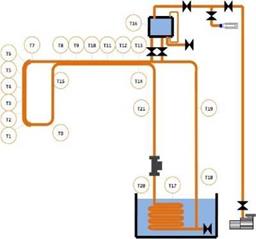

As shown in Fig.1(b), some temperature measurements are located around the body of the tubes. T0 is to measure the inlet temperature to the evaporator. Ti to T6 are to measure the temperature inside the evaporator. T7 is to measure the exit temperature of water from the evaporator. T8 to T13 are to measure the temperature in the heat exchanger (condenser). T14 and T15 are to measure the inlet and outlet temperature of heat exchanger (condenser). T16 is to measure the temperature inside the top heat storage. T17 is to measure the temperature inside the water bacth controller (cooler). T18 is to measure the inlet temperature to the water batch controller. T19 is to measure the outlet temperature from the heat exchanger and the top heat storage. T20 is to measure the outlet temperature from the water batch controller. T21 is to measure the outlet temperature from the flow meter. To investigate more details the performance of this IMT model, some parameters are varied. Heat input are varied with 100, 200, and 300W, comparing with the previous report were 200 and 400W [5]. The inclination angle between the evaporator and the top heat storage are varied with 00, 50, and 100. The remained water in the top heat storage are varied with 93%, 77%, and 61%. The water batch

|

|

controller keeps the temperature at 400C and one experiment takes 90 minutes and the data is collected for every 30 seconds.

a. IMT Model — experimental set up b. Temperature measurement position

Fig.1. Experimental set up and temperature measurement position for IMT Model

Table 1 shows the 14 experiments with varied parameters. There are 6 experiments for heat input 100W, which are Exp.1 (100W, 00, 93%), Exp.3 (100W, 50, 93%), Exp.6 (100W, 50, 77%), Exp.8 (100W, 100, 93%), Exp.10 (100W, 100, 77%). Exp.13 (100W, 100, 61%). There are 4 experiments for heat input 200W, which are Exp.4 (200W, 50, 93%), Exp.7 (200W, 50, 77%), Exp.11 (200W, 100, 77%), Exp.14 (200W, 100, 61%). There are 4 experiments for heat input 300W, which are Exp.2 (300W, 00, 93%), Exp.5 (300W, 50, 93%), Exp.9 (300W, 100, 93%), Exp.12 (300W, 100, 77%).

|

Table 1. The experiment with some varied parameters

|

The performance of these experiments can be evaluate by two factors, efficiency and steady circulation. Fig.2 shows the experimental results for heat input 100W with variation of the inclination angle and the remained water in the top heat storage. There are six experiments have been done for heat input of 100W. There are two experiments which gave the higher efficiency and a steady circulation. They are Exp.3 (100W, 50, 93%) and Exp.6 (100W, 50, 77%). The other 4

|

experiments which gave the low efficiency and unsteady circulation are Exp.1 (100W, 00, 93%), Exp. 10 (100W, 100, 77%) and Exp.13 (100W, 100, 61%).

Fig.3 shows the experimental results for heat input of 200W with variation of the inclination angle and the remained water in the top heat storage. There are 4 experiments have been done for heat input of 200W. Exp.4 (200W, 50, 93%) and Exp.7 (200W, 50, 77%) shows a good performance with higher efficiency and steady circulation but the performance of Exp.11 (200W, 100, 77%) and Exp. 14 (200W, 100, 61%) are very poor, means that lower efficiency and unsteady circulation.

Fig.4 shows the experimental results for heat input 300W with variation of the inclination angle and the remained water in the top heat storage. There are 4 experiments have been done for heat input of 300W. The performance of Exp.2 (300W, 00, 93%) and Exp.5 (300W, 50, 93%) are very poor, means that lower efficiency and unsteady circulation. Exp.9 (300W, 100, 99%) and Exp.12 (300W, 100, 77%) show good performance with higher efficiency and steady circulation.

|

Table 2. Summary of the experiments

|

Table 2 shows the summary of the experiments. The highest efficiency for heat input 100W is achieved by Exp.6 (68%) and the lowest efficiency is achieved by Exp.13 (-0.3%). For heat input 200W, the highest efficiency is achieved by Exp.7 (59%) and the lowest efficiency is achieved by Exp.11 (33%). The highest efficiency for heat input 300W is achieved by Exp.12 (69%) and the lowest efficiency is achieved by Exp.2 (41%). The highest overall efficiency for these experiments is achieved by Exp. 12 (69%).

The performance of thermosyphon with heat source near the top and heat sink at the bottom was studied by varying the operation parameters of heat input, inclination angle, and the remained water in the hot water storage. Result shows that the inclination angle and the remained water in the top heat storage are the important parameters which can influence the performance of thermosyphon.

Acknowledgement — The support of “High-Tech Research Centre Project for Private Universities: matching fund subsidy from MEXT, 2007-2011” for this research is appreciated.

1. F. F. Jebrail, M. J. Andrews, “Performance of A Heat Pipe Thermosyphon Radiator”, International Journal of Energy Research, Vol. 21, 101-112 (1997)

2. G. L. Morrison, “Solar Water Heating”, Solar Energy edited by J. Gordon, 2001, International Solar Energy Society, p.223-289

3. R. Khodabandeh, “Heat Transfer in The Evaporator of An Advance Two-Phase Thermosyphon Loop”, International Journal of Refrigeration 28 (2005) 190-202

4. S. I. Haider, Y. K. Joshi, W. Nakayama, “A Natural Circulation Model of The Closed Loop, Two Phase Thermosyphon for Electronics Cooling”, Journal of Heat Transfer — October 2002, Vol. 124 / 883

5. S. Ito, N. Miura, K. Tateishi, “Studies of A Thermosyphon System with A Heat Source Near The Top and Heat Sink at The Bottom”, Solar World Congress, Beijing, September, 2007

6. S. Ippohshi, S. Tabara, K. Motomatu, A. Mutoh, H. Imura, “Development of A Top-Heat Mode Loop Thermosyphon”, The 6th ASME-JSME Thermal Engineering Join Conference, March 16-20, 2003

7. Y. Maydanik, “Loop Heat Pipes-Highly Efficient Heat Transfer Devices for Systems of Sun Heat Supply”, Proceedings 1 of Eurosun 2004 Conference, 2004, p.470-47

Department of Materials Science, Tallinn University of Technology, Ehitajate tee 5, 19086, Tallinn, Estonia, e-mail: teolan@staff. ttu. ee

Two-positional exposure (discrete tracking) of PV-modules (or flat-plate solar thermal collectors) allows increased efficiency mainly due to a prolonged daily interval of performance. A stand-alone PV-module in the regime of the two-positional tracking is the most effective. If such PV-modules are concentrated into a farm, they will mutually shadow each-other during some transient shading interval in the sunny morning and in the sunny evening. For that reason a tracked PV-farm performs somewhat less effectively than the said stand-alone PV-module and its usage may be problematic. Therefore, the use of a tracked PV-farm is analyzed and discussed in this paper. In the farm the gain (increased efficiency) of discrete tracking depends on the relative distance between the tracked modules and the deflection angle. A PV-farm with a two-positional exposure is beneficial if the distance between the neighbor modules surpasses the two-three values of their width.

Keywords: PV-farm; two-positional exposure; shading interval; gain; deflection angle; relative distance

Performance and profit of a stand-alone solar collector with two-positional tracking was analyzed in [1]. Such a collector has an axis around which it can be deflected (rotated) into two positions: eastward (AM) and westward (PM). In the conditions of Nordic region (~60° N) and maritime climate, the average statistical gain (increased efficiency or the profit) may reach up to 130%, depending on the initial tilt angle, deflection angle and share of direct radiation. Due to the positive correlation of the gain on the ratio of the direct and the diffuse radiation, the average gain is evidently higher for the continental climate. As a stand-alone solar collector is usually an exception, it is important to analyze the performance of the collector in a solar farm, which consists of several tracked collectors installed in parallel. Due to mutual shading their performance is somewhat less effective, therefore it is required to find out what the extent of difference is and which circumstances influence the gain. This study has focused on these issues. Principally, there is no difference between the behavior of tracked solar-thermal collectors or tracked PV-modules, but we will look at PV-modules first. Tracking solar-thermal collectors are complicated to use due to their (usually rigid) piping. Therefore we concentrate on the PV-modules. The theoretical analysis was done by a self-created computer simulation model. Experimental testing was performed by help of the physical model.

The CTSS Method was developed by ITW in Germany and is based on separate tests of the most important components like the collector (according to EN 12975-2), the store (according to ENV

12977-4) and the controller (according to ENV 12977-2). Based on the parameters evaluated for the components, the thermal performance of the complete system is predicted using a component — based system simulation program such as TRNSYS [7]. The application range of the CTSS method is very flexible because of its component-oriented approach. It is possible to apply the method on nearly every system configuration, including solar combisystems. The performance can be determined for different reference conditions (meteorological data, load profiles) by means of annual system simulation [5]. The performance indicator is the energy used by the auxiliary heater which implies that the solar combisystem is always tested in combination with the heater.

One of the major advantages is the flexibility of the method but it is quite difficult to examine the system control strategy in real, because links between the components are just simulated.

The overall performance of a thermal system simulated with TRNSYS and in particularly of the heat rejection technologies is strongly influenced by the type of components employed in the simulation and the control strategy of the system.

The control strategy of the present system is as follows. The cooling load has to be satisfied with water at 7°C and the chilled water returns from the load at 12.5°C. It is supposed that all the cooling production is absorbed by the loads. Solar collectors heat up the hot storage and the pump of the solar collector loop is started as the difference between collector outlet and storage bottom temperature

exceeds 8 °C. Water from the top of the storage is sent to the generator of the absorption chiller. The start up Temperature of the chiller is set to 72°C and the air-cooled heat exchanger or the cooling tower start up matches with it. In this study the fans were not controlled nor with a variable frequency Drives (VFDs) neither with two speed motor steps. Controlling a motor with a VFD is of author’s interest and this technology will be considered for the next activities [12]. As can be noted the system control strategy is kept very simple to avoid complications in the simulation.

The investigation is carried out for three different Italian sites: Bolzano (latitude 46°30’ N) with an alpine climate, Rome (latitude 41°54’ N) with a Mediterranean climate and Palermo (latitude 38° 7′ N) with a very hot climate. This should give an idea on how different locations lead to different energy and economic performance of the heat rejection equipment Each location was simulated for both the heat rejection technologies: dry cooler and wet cooling tower. The solar collector slope was varied for each location and was equal to 35, 30 and 25°.

Since the choice of the heat rejection technology gets influenced by economic considerations, the definition of the installation and running costs is of primary interest. The economic parameters assumed for the present analysis are reported in Table 1.

|

Primary costs, Cinv |

|

|

Air-cooled heat exchanger Cooling towers |

86 — 120 €/kWth 50 — 70 €/ kWth |

|

Running costs |

|

|

Electricity, CEn, ele Water, CEva |

0.2 €/kWh 1 €/m3 |

|

Presen t worth _ figures |

|

|

Life time, nLt |

20 years |

|

Table 1. Economic parameters |

From the data collected for Flat Nos. 3 and 6, one could calculate the average volume of hot water used per couple. Figure 7 shows the mean daily hot water usage for every month. It follows that the minimum conservative hot water consumption would be in the region of 20 litres/person/wash (Flat 3), while 30 litres/person/wash would be required for average users (Flat 6). It is noted that only showers were used and no baths. Typical energy savings, payback period and carbon dioxide mitigation

Figure 8 shows the equivalent energy savings from solar hot water usage for Flat Nos. 3 (500 kWhthermal/year) and 6 (1,414 kWhthermal/year). Although, the more careful users (Flat 3) saved less energy but they have saved more water than Flat 6. The important point here is not the amount of energy saved but that users were satisfied with the performance of their systems, without resorting to electric back-up heating.

If one considers the FUPF for each flat of Figure 5 above, and calculate the maximum energy savings that could be obtained for both cases, excluding the summer months, then one would obtain 1,500 and 1,850 kWhthermal/year for Flat Nos. 3 and 6, respectively. Hence, on average each 150-litre water-inglass evacuated-tube solar system can potentially save 1,650 kWhthermal/annum.

Alternatively, one could have used an electric boiler as is usually the case for Malta, with an efficiency of 90%. Hence, the actual electricity savings would be 1,833 kWhelectric/annum. Therefore, it could easily be calculated that the payback period of these solar systems were around 4 years, based on a net cost — after Government grant — of €1,000 and an average electricity rate of €0.13/kWh.

Moreover, since every kWh saved would have generated 0.87 kg of carbon dioxide at the power station [7] , the potential savings for the ten solar heaters, would amount to 16 tonnes of carbon dioxide per year, excluding the summer months.

It is important to get feedback about real performances, in order to increase knowledge in different fields and to be able to quantify the real contribution of solar plants in the reduction of primary energy consumption and green house gases emissions.

It must be pointed out that very few in situ monitoring works have been performed until now, not only for solar plants, but in all fields of buildings construction and especially for evaluation of space heating, Domestic Hot Water or ventilation systems. Due to the fact that solar systems are assisted by auxiliary systems, the over cost of the solar part has to be as much cost effective as possible. Therefore it is not possible to accept systems that don’t work on the best possible way,

otherwise the economic balance of the operation will be decreased, and confidence by the end user will be reduced.

Thanks to the result of the qualitative and the technical evaluation, the in-situ monitoring will start with the installation of the monitoring equipment. In order to succeed in this operation and to have consistent data, the same methodology will be used by all the partners: measured data (temperature, flowrate, …) will be exploited to obtain energy data in the different countries.

|

In-Situ monitoring

Table 1. Preliminary list of system that will be evaluated (This list is subject to change) |

Up to now, some specifications for the monitoring equipment have been investigated in order to have a common base for the evaluation of solar combisystems and in order to have some intercomparisons between the different partners involved in CombiSol. Based on these specifications, some guidelines for calculation of saving indicators have been written: these guidelines will serve as reference for publishing the results during the dissemination phase.

M. Lundh1*, E. Wackelgard1 and A. Henning2

1 Department of Engineering Sciences, Uppsala University, The Angstrom Laboratory, P. O. Box 534, SE-751 21

Uppsala, Sweden

2 Solar Energy Research Center (SERC), Dalarna University, SE-781 88 Borlange, Sweden

Corresponding Author, Magdalena. Lundh@angstrom. uu. se

Solar collector systems require an auxiliary heat source in temperate climates, and one system solution increasingly used in Sweden is combined solar and wood pellet heating. The development of integrated systems adjusted to the combination is however slow. To investigate the process towards a concept of solar and pellet heating, ten semi-structured qualitative interviews were performed with representatives for the trades during autumn and winter 2007. The present development and experienced obstacles were discussed, and conditions necessary for further progress and to reach success were identified. Other aspects found in the interview material will be analysed and reported in future papers.

The main condition to reach increased market shares is extensive marketing and information to the public, for which larger assets are required. The governmental influence, both by taking stand and making long-term regulations, as well as the installer corps influencing the costumer’s choice of system were stressed. A recent change in attitude is however clear, and the combined systems are by all informants regarded close to reaching general market establishment.

Keywords: solar heating, pellet, combined systems, interviews

Solar collectors can not supply all heat demanded in a building in temperate climates; an auxiliary heating system is always required. There are several possible solutions, where the most common Swedish combination is with electrical heaters. One system solution that has become more frequently used over the last years is however combined solar and wood pellet heating. In the beginning, separate standard solar heating and pellet heating systems were combined, and still few companies offer well — integrated combined solutions. The development of a concept of combined solar and pellet, on the other hand, means that the solar collectors and pellet heating units are well-suited to be operated as one system and that the combination of two energy suppliers does not cause the end-user or installer additional effort compared to a single energy supply system. It should rather be experienced as one system. Besides Sweden, combined solar and wood pellet systems are also marketed and sold in countries like Germany, Austria and United Kingdom.

Solar heating systems as well as pellet heating have been considerably developed since the 1970’s. Although the technologies themselves are today well-developed and the heating systems have reached cost-effectiveness, the development of combined systems is slow. There are even advantages, such as

increased system efficiency and sustainability that advocate combined systems rather than individual solar/electricity and pellet heating respectively. But how does a new system solution evolve and what obstacles towards extended market dissemination are experienced by the trades? To investigate the background of the modest market introduction rate of combined solar and pellet systems an interview study was performed.

The aim of this study is to investigate the development of the concept of combined solar and pellet heating systems for single-family houses. Obstacles as well as possibilities experienced within the Swedish trades are to be distinguished. The aim has not been to cover all members of the solar and pellet industries; representatives not included in this study may have disparate opinions or proposals. The Swedish solar and pellet industries are however relatively small and a large fraction of the well — established members have been interviewed or involved in the meetings attended. This study rather aims at lifting some of the main issues experienced as important to the trade people. The outcome of this study could for example be used to direct future research, political means and market focus to increased use of combined solar and pellet systems, and in the long run towards sustainability. There are most likely similarities to other areas within the renewable energy sector.

This part of the reporting focuses on results on experienced obstacles against further development and prerequisites to increase the market shares.

The present state of combined solar and pellet heating systems was first investigated by a literature and internet survey. Trade papers and magazines were searched for advertisements about the systems and web pages of Swedish manufacturers, producers and retailers were visited to investigate how solar and pellet systems are described. The outcome of this pre-study constituted the basis for formulation of interview questions as well as the choice of informants.

To map the process towards a complete system solution or concept with combined solar and wood pellet heating, ten qualitative interviews were performed during autumn 2007. The informant group comprised ten persons involved in the process in different ways, such as manufacturers, retailers, installers and representatives for the solar and pellet trade organizations respectively. Some of the informants have more than one role in the trades, such as being both representative for a trade organisation and a company producing or selling heating systems.

The interviews were semi-structured, which means that topics and questions were formulated in advance, but the interviews more took the form of open discussions and the order of questions was not strictly followed. During the interviews follow-ups were made on new related themes. The informants were given a brief introduction to the background and aim of the project before the interview.

The informants were first asked to give a short background to themselves and their company or organisation. The discussion was then focussed on attitude to the heating systems as well as to the solar and pellet trades, obstacles and possibilities with combined systems, but also the present and past development, prerequisites for further development and knowledge. The interviews were recorded and partly transcribed. The material was then categorized and analyzed according to [1, 2] to find trends in opinions, ideas and problem identification.

Three different meetings were also attended to study the interaction between the actors and take part in the discussion of the investigated issue. Two of the meetings were between company representatives within the wood pellet industry as part of the initiative from the Swedish Energy Agency “Pellet heating — future heating” (“Pelletsvarme — framtidsvarme”) while the third meeting was a joint gathering between the interest organisations for solar thermal, solar power, wood pellet and wind power, where the Swedish Solar Energy Association was the main organiser. All meetings took place during autumn and winter 2007.

The interviewer has a background in technology and science, but is part of an interdisciplinary research program, where interview studies have also been performed in cooperation with social scientists earlier. During this research project the interviewer have had regular contact with a social anthropologist for methodological issues.