Как выбрать гостиницу для кошек

14 декабря, 2021

2.2. Results of Summer Shading Simulation Profiles

The results from computer building simulations for the summer shading profiles are analyzed and assessed with the same procedure as for winter. The optimum fenestration profile for summer as defined below is taken as the basis in these series of combinations.

a) Optimized Fenestration Shading Strategy for Summer

The optimised fenestration strategy for summer, derived in previous work [1], is outlined as having all glazed area shaded during the day time to obtain minimum solar gains and hence comfort indoor conditions ranging between 23.3 — 25.4 degrees Celsius (Table 1, 1.4).

b) Half Area of South window Shutters Unshaded

When half of the south window area (17.5m2) is left unshaded during summer days the indoor temperature increases by 0.1 to 0.6 degrees Centigrade (Table 2, 1.3). The small temperature rise seems out of proportion with the large extent of glazing area left unshaded; this is attributed to: Orientation — South orientated windows have no direct solar insolation in the summer.

Design-The optimised design of overhangs and extended vertical walls for south glazing, derived and employed at an earlier stage of the study on “Shading” [1] i. e. shade the solar aperture from the high summer sun while permitting rays from the low winter sun; the optimised design does not leave much space for any further improvement for sun control.

The temperature rise which appears in the current simulation is attributed to the decrease of thermal resistance of windows due to the absence of shutters.

c) All South Window Area Unshaded

When all south window shutters are left unshaded during summer the indoor temperature increases

at the same rate as above (0.1 to 0.5 degrees Celsius, Table 2, 1.2 and 1.3). This increase in temperature deviates from the ones succeeded with optimised design by 0.2 to 1.0 degrees Centigrade (Table 2, 1.4 and 1.2). However the indoor temperature continues to range within comfort levels (23.5 to 26.5 degrees Celsius). The maximum temperature rise (1.0 degree Celsius) reached indoors occurs in the early afternoon and evening hours between 14.00-22.00 hours (Tables 2, 1.2 and 1.4).

d) South and West Windows Unshaded

If in addition to south windows the shutters of west windows are left open during summer day the indoor temperature shows a further rise of 0.1 degree Celsius only at certain hours of the day (table 2, 1.1). The small increase is associated with the small West window area (0.50m2).

e) All Windows Shutters Unshaded

A similar rate of increase presented above (0.2 degrees) occurs when the glazed area (3.50m2) of north windows is left unshaded during the summer (Table 2, 1.0 and 1.1). The indoor temperature is maintained within comfort levels (23.8-26.6 Degrees Celsius). Maximum temperature is reached in the afternoon and early evening hours (16.00-20.00 hours). The peak temperature reaches 26.6 degrees.

Francisco Craveirol, Vi’tor Leal2* and Eduardo Oliveira Fernandes2

1 AdEPorto, Porto Energy Agency, R. Gongalo Cristovao, 347, room 218, 4000-270 Porto, Portugal 2Faculty of Engineering of the University of Porto, Department of Mechanical Engineering, , Rua Dr.

Roberto Frias, 4200-465 Porto, Portugal

* Corresponding Author: Vitor Leal, vleal@.re. up. pt

Since 2006 Portugal has a new thermal regulation and since 2008 an energy labelling scheme which applies to significantly retrofitted buildings the same requirements as for the new ones. There are requirements related with the envelope and with the energy supply systems, since the nominal primary energy consumption for heating, cooling and domestic hot water is evaluated. An additional requirement is the installation of solar thermal collectors for domestic hot water heating if the cover of the building has a suitable orientation.

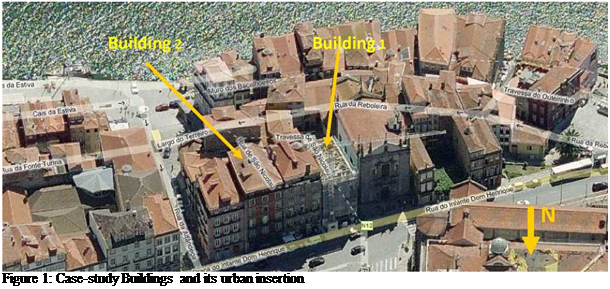

Recognising the specificity of historical areas, the regulation foresees the possibility of exemption of full compliance for buildings located in historical areas if justified incompatibilities are found. This paper explores the issues arising when applying the regulation to six apartments of two buildings in the historical areas of Porto undergoing a retrofitting process. The results show that it is possible to comply with the energy requirements of the regulation without interfering with the building esthetical appearance and without using solar thermal collectors. However these seem to be crucial to achieve class “A”or “A+” labels.

Keywords: Buildings, Retrofitting, Energy Labelling, Solar collectors

1. Introduction

The recently published Porto Energy Matrix [1] revealed that buildings of Porto represent about 60% of the primary energy demand of the city. The urban management and the building design thus play a decisive role in the city energetic-environmental performance. This applies to new buildings, which are a golden opportunity for doing well, but also to existing buildings, which account for most of the building stock and are crucial to achieve large-scale effects.

In the city of Porto about 1/3 of the lodges are located in the historical area of the city [2]. Although most of this area is classified as world heritage by UNESCO, most of these buildings are very old and need a retrofitting process which upgrades their value and performance as buildings on their own but also their contribution to the recuperation of the old town as quality space. In order to foster this effort of retrofitting the old town, the municipality created a special office, the PortoVivo SRU — Sociedade de Reabilitagao Urbana [3]. This work was done in cooperation with the Porto Energy Agency [4] and the SRU with the objective of assessing the compatibility of the thermal regulations with the retrofitting process. It presents a first spot assessment of the initial status of compliance with the RCCTE in the retrofitting of the Porto downtown historical residential buildings, as well as the identification of some corrective measures and the quantification of its impact in terms of the energy labelling.

The thermal regulation in place in Portugal for residential buildings is the RCCTE [5] which was adopted in 2006 as part of the legislative pack that implemented the transposition of the Energy Performance of Building Directive [6]. The regulation itself foresees the possibility of exception for buildings located in historical centres, but only if a clear demonstration of incompatibility with the patrimonial values is made.

In terms of energy requirements, the fulfilment of the regulation implies the simultaneous fulfilment of the following requirements:

i) Minimum requirements for the envelope elements (U-value and solar factor)

ii) Heating needs (useful energy, Nic) inferior to a maximum level allowed (Ni).

iii) Cooling needs (useful energy, Nvc) inferior to a maximum level allowed (Nv).

iv) Hot water needs (final energy, Nac) inferior to a maximum level allowed (Na)

v) Total primary energy (Ntc) inferior to a maximum allowed level (Nt).

|

(kgoe/m[10].year) |

The calculation of the total primary energy needs Ntc considers that the domestic hot water needs are satisfied at 100%, while the nominal heating and the cooling needs are only satisfied at 10% (due to use patterns). Ntc is computed as (eq.1) :

Where hi and hv represent the conversion factors from final to useful energy, while Fpui, Fpuv and Fpua represent the conversion factors from final to primary energy.

If (and only if) all the previous criteria i) to v) have been met simultaneously, then an energy class can be determined. The energy class is established through the quotient between the estimated primary energy use and its maximum allowed by regulation, with class transitions at each 25% improvement. The minimum allowed class for new or significantly retrofitted buildings is B — (table 1).

|

Table 1: Energy labelling as function of the relationship between the calculated primary energy use (Ntc) and the maximum allowed (Nt).

|

Table 2 synthesises the main geometric and thermal properties of the buildings (as foreseen in the retrofitting design, i. e. the thermal characteristics are those previewed for after the retrofitting). Other important features of the buildings are the massive granitic walls and the fact that some of the surrounding streets are very narrow and do not allow significant solar incidence in some facades. Also, even in the windows with good solar exposition, the shadings are usually internal and the retrofitting designs usually try to keep this feature.

Table 3 shows the set of heating and cooling equipments considered for the calculation of final and primary energy.

|

The first important note that was drawn from the analysis of the retrofitting design processes was that they stated right at the beginning that because the buildings where at an historical area they were exempt from compliance with the RCCTE, and therefore in most cases no effort was made to ensure compliance. The view of the authors of this article is that such an assumption cannot be taken a priory, and calculation will be made in section 3 to analyse whether there are in fact justified incompatibilities that may exempt the buildings from the application of the thermal regulation or not.

|

Table 2: General characterization of the buildings/apartments after retrofitting.

|

|

Table 3: Equipments considered in the base-case.

|

D. Geelen1 , S. Y. Kan1, J. C. Brezet1

1 Delft University of Technology, Faculty of Industrial Design Engineering, Design for Sustainability

Landbergstraat 15, 2628CE Delft, The Netherlands

* Corresponding Author, d. v.geelen@tudelft. nl

How do product designers apply photovoltaic solar technology in consumer products? That question is addressed in this paper. Six design projects were analysed for the application of guidelines from the Delft Design Approach. This is a generic design approach for the design of renewable energy powered products, based on a phase model for product design, the Energy Matching Model and a Design for Sustainability benchmark. The analysis indicates that structural application of the guidelines facilitates the design process, and makes it more transparent. Further research and development for the Delft Design Approach is desirable in order to improve the development of PV powered products.

Keywords: PV powered consumer products, product design guidelines, energy matching.

1. Introduction

Imagine you are an industrial designer, and not an expert in solar energy technology, such as photovoltaics (PV). How would you design a PV powered consumer product?

This paper addresses the research question how young product designers deal with the application of PV technology in consumer products and to what extent they make use of the Delft design approach for the creation of successful PV powered products?

The Delft design approach is a generic design approach for the design of renewable energy powered products, taught at the faculty of Industrial Design Engineering of the Delft University of Technology. The approach is based on the phase model of the design process presented by Buijs and Valkenburg [1], the work on energy matching by Kan [2] and the Design for Sustainability (D4S) manual [3].

Six design projects were analysed to answer the research question. The projects discussed in this paper are recent master graduation projects executed at the faculty of Industrial Design Engineering of Delft University of Technology. All design projects were aimed to create a PV powered consumer product. All involved designers were familiar with the basis of the Delft design approach.

Mele, Edgardo1; De Benito, Liliana2; Garzon; Beatriz[12].

Architect. Chubut Rural Habitat Program Member, Instituto Provincial de la Vivienda de Chubut,

Argentina. edmele@hotmail. com

Architect. Chubut Rural Habitat Program Coordinator, Instituto Provincial de la Vivienda de Chubut,

Argentina. lilianadebenito@yahoo. com. ar

Architect. FAU-SeCyT Universidad Nacional de Tucuman Project Director. CONICET Investigator. Member of Chubut Rural Habitat Program, Instituto Provincial de la Vivienda de Chubut, Argentina.

The purpose of this work is to develop a model of management and production of solar houses build by the State so as improve life conditions for rural settlers in three villages in Chubut, in southern Argentina. These dwellings show the development of architectural prototypes, suitable to geographical and climatic rigorous conditions. The prototypes incorporate appropriate technology (soil-cement, rubblework, solar cover collectors, etc.); the possibility of using forms of renewable energies such as solar to heat water or air, to cook, to dry clothes or as aeolian energy to generate electrical energy; the rational use of the firewood as fuel and assisted attended auto-construction. The Methodology selected is the Participative Action Research. It has been used not only to acknowledge this reality but to transform it. The participation of the people involved as well as instruments for changing their reality. The bioclimatic guidelines and strategies as well as the architectural covering and dwellings’ architectural typology for their climate adaptation and the proposed technological systems have been determined and assessed. These houses have built with the conjoint effort of both the beneficiaries working co-operatively and the team of technicians in charge of the project. The realization of this project has been possible thanks to the users’ enthusiastic and highly qualified participation in the appropriation of alternative technological systems. It is thanks to these systems that the necessities and/or environmental, technological, and functional conditions of families and communities have been attended to strengthening at the same time, the concept of belonging and evaluating a re-evaluating a community’s natural and cultural milieus.

Key Words: Domestic Rural Habitat, Sustainable Building Adequateness, Social Interest Solar House.

The model of unsteady energy transfer through, outside and inside building elements has been developed [1]. In order to reduce the number of variables to a level that allows different design options of a room to be compared in a meaningful way it has been useful to make some simplifications. A fixed room size (16 m2) and room temperature requirement (constant in time and space, equal to 200C) have been assumed. The model of unsteady energy transfer outside, through and inside the wall has included heat conduction and heat capacity of wall elements, heat convection with indoor and outdoor room surrounding, and radiation exchange between indoor and outdoor room surrounding and the wall. Solar radiation absorption and reflection on wall surfaces, and the effects of orientation and inclination on them have been considered.

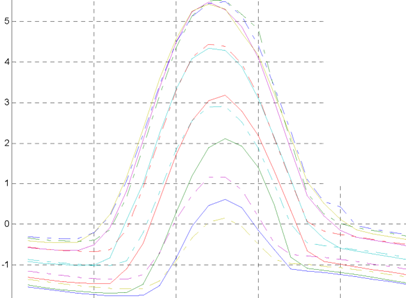

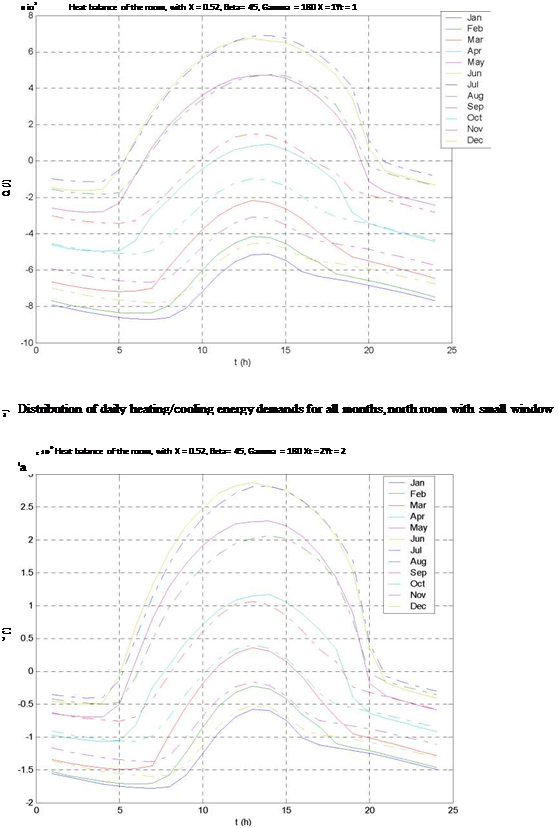

The energy balance of a room includes energy transferred through opaque and transparent elements, including direct transfer of solar energy through windows, energy needed for ventilation, and energy supplied by the internal heat sources. It has been assumed that energy supplied by the heating/cooling system (HVAC) is treated as internal heat source. According to assumption made, the indoor temperature is constant in time and space. It means that HVAC system operates all the time providing required (by the constant indoor temperature) heating or cooling energy. The mathematical model developed has been used for numerical simulation using Matlab as the programming language. It allows many cases of different location of rooms to be evaluated. Selected results of simulation studies of attic rooms are presented in Fig. 5-8. Figures 5-8 present distribution of heating/cooling demands for the whole averaged year (averaged curves for every month) with the south and north inclined envelope with small and big windows, respectively.

For the south orientation the maximum hourly cooling demand is at noon in July and August and for a room with the small window it is about 1,3 MJ and with the big window it is about 5,5 MJ. There is no cooling demand from November till January for the room with the small window. Apart from these months during a day time there is need for cooling. Duration of cooling mode depends on the month of the year and depends on solar irradiance and ambient temperature. For the room with the big south window all year round during day time there is need for cooling (different number of hours of operation of the cooling system for different months). In winter there is heating demand with maximum early in the morning (about sunrise) in January and it accounts to 0,8 MJ/h for the room with the small window and to 1,8 MJ/h for the room with the big window.

For the north orientation the maximum hourly cooling demand is at noon in July and June and for a room with the small window it is about 0,7 MJ/h and with the big window it is about 2,8 MJ/h. There is no cooling demand from October till March for the room with the small window. In the rest of the year during a day time there is need for cooling, the duration of cooling mode depends on the month of the year (because of the level of solar irradiance and ambient temperature). For the room with the big south window there is no need for cooling from October till February, during the rest 8 months the cooling mode exists with different operation time. In winter there is heating demand with maximum early in the morning (about sunrise) in January and it accounts to more than 0,8 MJ/h for the room with the small window and to 1,8 MJ/h for the room with the big window.

It is evident that night heating demands are resulted from the ambient temperature fluctuation. Heat losses are mainly through windows. Opaque walls have the designed thermal capacity. Heat stored during day time influences indoor climate in the night. During day time the influence of solar radiation and energy transferred through windows is evident. Solar radiation causes need for cooling in summer and reduces heating demand in the rest of the year. Solar gains could be so high that there is no need

|

for heating for a few or several hours per day. It is remarkable that shapes of curves of solar radiation through windows (Fig. 1-4) are similar to curves of energy demands (Fig. 5-8) during the day time.

Fig. 5. Distribution of daily heating/cooling energy demands for all months, south room with small window

x 106 Heat balance of the room, with X = 0.52, Beta= 45, Gamma = 0 Xt = 2Yt = 2

|

|

2. Conclusions

Figures 5-8 show daily distribution of energy required per hour to meet the heating/cooling demands of the rooms under consideration. Table 1 presents the sums of seasonal heating/cooling demands in the form of seasonal energy indexes (energy required to meet heating/cooling demands for the whole heating or cooling season with regard to 1 m2 of the room floor area). The space heating energy consumption indexes are below limits given by national standards (72,5 kWh/(m3a)). No regulations exist for space cooling indexes, however, it is evident that they are very high and limits for space cooling should be introduced as soon as possible.

|

Table 1. Seasonal energy consumption indexes for rooms at attics with different orientation

|

Other results of simulation studies show that cooling season for south, east and west oriented attic rooms (floor area 16 m2, external wall area 12 m2, 3 layers, Uwall= 0,3 W/m2K, window — 4 m2, Uwin=1,6 W/m2K) lasts 8, 6 and 6 months and the cooling demands are about 5500, 3800, 3300 MJ per season respectively. The heating season for the same rooms lasts 4, 6 and 6 months and the heating demands are about 2000, 2700, 3000 MJ per season respectively. In all cases cooling demand is higher than heating demand, for the south room even nearly three times, which is surprising for high latitude country (Warsaw 520 N).

It appears that overheating in summer due to high solar irradiation and energy transmitted and absorbed in glazing can be a real problem for rooms in attics. To assure stable indoor thermal comfort of rooms in attics (mainly to avoid overheating, according to the assumptions made in the model), i. e. to keep a constant temperature in the rooms under consideration, it is necessary to use shading, e. g. external blinds. If no shading is applied then air-conditioning systems, which are usually electrically driven and consume a lot of primary energy, must be used. Of course there is one simple conclusion: not use the attic spaces for living spaces.

References

[1] D. Chwieduk, (2006). Modelowanie i analiza pozyskiwania oraz konwersji termicznej energii promieniowania slonecznego w budynku. IFTR Reports, 11/2006, Warszawa.

[2] D. Chwieduk, Some Aspects of Modeling the Impact of Solar Energy on the Energy Balance of a Room, Solar Energy (in print).

[3] D. Chwieduk, B. Bogdanska, Some recommendations for inclinations and orientations of building elements under solar radiation in Polish conditions, Renewable Energy Journal, 29 (2004) 1569 — 1581.

[4] S. Sherbiny, G. Raithby, K. G. Hollands. Heat transfer by natural convection across vertical and inclined air layers, Journal of Heat Transfer 104 (1982) 96-102

[5] D. T. Reindl, J. A. Duffie, W. A. Beckman, Evaluation of Hourly Tilted Surface Radiation Models, Solar Energy, 45 (1999) 9 — 14

An increasing interest and application of the glass material in architecture and Portuguese construction can be observed through the buildings of the built where it is more used in the service buildings-Fig.1.

It is a common sight in the service buildings (mainly office buildings) built in the last decades, the glass material as constituent part of the envelope and in considerable proportions. The residential buildings, usually present, lower glazing areas than the service buildings. Meanwhile, it is possible to note a growing increase in the glazing areas in the facades of the residential buildings built in the last decades (Fig. 2), and even, some of the residential buildings built in the last years have practically glassed facades similar to the service buildings, see Fig. 3.

|

1970

|

Fig. 2. Evolution of residential buildings and glazing areas in the last decades (Valmor Awards).

Large glazing areas in residential buildings are architectural solutions or options that allow a more homogeneous exterior aesthetic view, scenery contemplation, greater transparency and luminosity; while having a direct influence in the comfort of its occupants, and are determinant for the building thermal-energetic performance (large glazing areas in a residential unit increases the potential for heat gain or loss). The residential buildings highlighted in Fig. 3 were selected for this study. Some flats of these buildings were monitored through the summer (2007) and winter (2007-2008). In this way this work will show the main results and observations of the monitoring.

For each project was assessed if the guidelines of the Delft Design Approach were systematically applied, and how the application of the guidelines contributed to an efficient and transparent design process.

Table 1 summarises the use of the Delft Design Approach guidelines per project. For the elements that are recommended to be addressed in the process is marked if it was actually addressed in a project.

Table 1. Analysis of design projects

|

Pupil Locator |

Solar Mobile P АПЛППИ1 ҐЛ |

BALL Light |

1 О 4 ей 4 о — a.< сл m h |

Solar Blox |

Solar Power Station |

||

|

Analysis |

|||||||

|

Phase model |

Technical analysis |

♦ |

♦ |

♦ |

♦ |

♦ |

♦ |

|

Function analysis |

♦ |

♦ |

♦ |

♦ |

♦ |

♦ |

|

|

Market research |

♦ |

♦ |

♦ |

♦ |

♦ |

♦ |

|

|

Energy Matching Model |

Guide in the process |

♦ |

♦ |

||||

|

MI 1 |

♦ |

♦ |

♦ |

♦ |

♦ |

||

|

MI 2 |

♦ |

♦ |

♦ |

||||

|

MI 3 |

♦ |

♦ |

♦ |

♦ |

♦ |

||

|

OMI / Overall energy |

♦ |

♦ |

♦ |

♦ |

♦ |

♦ |

|

|

balance |

|||||||

|

Figure of Matching calculation |

|||||||

|

Benchmark |

Product inventory |

♦ |

♦ |

♦ |

♦ |

♦ |

|

|

Detailed benchmark |

♦ |

♦ |

|||||

|

Synthesis |

|||||||

|

Phase model |

Evaluation of technical |

||||||

|

possibilities |

♦ |

♦ |

♦ |

||||

|

Concept development |

♦ |

♦ |

♦ |

♦ |

♦ |

♦ |

|

|

Consumer research |

♦ |

♦ |

♦ |

♦ |

♦ |

||

|

Energy Matching Model |

Guide in the process |

||||||

|

MI 1 |

♦ |

♦ |

|||||

|

MI 2 |

♦ |

♦ |

|||||

|

MI 3 |

♦ |

||||||

|

OMI |

♦ |

♦ |

♦ |

||||

|

Figure of Matching calculation |

|||||||

|

Optimisation |

|||||||

|

Phase model |

Production process design |

||||||

|

Detailed design |

♦ |

♦ |

♦ |

♦ |

♦ |

||

|

Concept testing |

♦ |

♦ |

♦ |

♦ |

♦ |

♦ |

|

|

♦ |

♦ |

♦ |

|||||

|

Energy Matching Model |

Guide in the process MI 1 |

♦ |

|||||

|

MI 2 |

♦ |

♦ |

♦ |

||||

|

MI 3 |

♦ |

♦ |

|||||

|

OMI |

♦ |

♦ |

|||||

|

♦ |

♦ |

♦ |

|||||

|

Figure of Matching calculation |

4. Conclusions

From the analysis of the projects, insight was created in how the guidelines of the Delft Design Approach for renewable energy products design were applied in the design process.

Per project there are differences in the approach of the analysis phase. In only two of the projects the Energy Matching Model was used as a guide to structure the analysis. This ensured that all aspects related to the energy chain were addressed. The PV technology analysis of these projects was more transparent than in the other projects. It is remarkable that after studying the Energy Matching Model, the designers adjusted the model to tailor it to their way of dealing with the design of a PV powered product.

The depth of the analysis showed differences as well. The more the designer learned about PV technology application, the better he/she could structure the design and explain to others how the final design developed. A better understanding of the issues involved in PV technology application affected transparency and efficiency of the design process.

Energy matching in the anaylsis phase can be considered a of the synthesis phase for the PV system of the product. Technical possibilities are explored and conclusions are drawn for the overall design of the product.

In two projects the PV solar energy system of the product was fully defined in the analysis phase of the project. As a result the Energy Matching Model and Figure of Matching were not used in the subsequent design phases. The other projects used the Energy Matching Model as a means to generate ideas and to evaluate ideas and concepts in terms of energy matching.

Another project in which the Energy Matching Model was not used in all design phases was the BALL light project. In this project PV technology application was hardly addressed. This may be explained by the fact that the feasibility of PV application for the product was already clear.

For energy matching calculations all the designers made a spreadsheet. Each spreadsheet was different in its use of formulas, input variables and output. A standardised calculation guideline and generic spreadsheet for PV powered product design can be valuable for a designer. The designer will save time, will have a spreadsheet that is understandable for others and can be used by others. Mistakes in the spreadsheet formulas, due to lack of experience of the designer, can be avoided. It is not expected that calculation guidelines can be used by designers without some basic knowledge in PV technology application, due to the specialised nature of the subject.

The designers did not do Figure of Matching calculations; only used the examples presented by Kan [2].

A product benchmark as recommended in the Delft Design Approach was done in only two projects. A product inventory was done en all projects The product inventories were meant to gain insight in the market, while with the benchmark also technical and user-product interaction issues related to the products were analysed.

This paper addressed the research question how young product designers deal with the application of PV technology in consumer products and to what extent they make use of the Delft design approach for the creation of successful PV powered products. The analysis indicates that the designers use many of the guidelines of the Delft Design Approach and the application of these guidelines seem to contribute to transparency and efficiency in the design process. In order to improve the practice of PV powered product design, further integration of the guidelines and tools for teaching material and textbooks is desirable. More knowledge on PV powered product design is also needed as technology development in this area develops very quickly. In the Design for Sustainability and Delft Design Institute program as well as in the Northern Solar Alliance program of the Cartesius Institute more attention is needed for integral design of PV powered products.

References

[1] J. Buijs, R. Valkenburg, (1997), Integrale productontwikkeling, Lemma, Utrecht

[2] S. Y. Kan, (2006), Energy Matching: Key towards Design of Sustainable PV Powered Products, Doctoral Dissertation, Delft University of Technology, Delft.

[3] M. R.M. Crul, J. C. Diehl (2006), Design for Sustainability — A practical approach for Developing Economies, UNEP.

[4] A. Stevels, (2007), Adventures in EcoDesign of Electronic Products 1993-2007, Delft University of Technology, Delft.

F. Cuadros, F. Lopez-Rodrfguez, C. Segador,

Escuela de Ingenierias Industriales de la Universidad de Extremadura. Campus Universitario,

Av de Elvas s/n. Badajoz. Spain.

Corresponding Author, ferlopez@unex. es

This communication is intended to present an example of bioclimatic architecture. In particular, the development of an intelligent zero-energy building (ZEB) in the campus of the University of Extremadura is described. Such building is projected to have an approximate surface of 1000 m2, and will be located in the outskirts of Badajoz. Specific concepts directly related to building design are put in practice, like for instance energy saving and energy efficiency, energy storage, environmental impact, etc. Besides, a comparative empirical analysis among conventional and renewable energy sources is carried out. Some of the specific technologies involved are: active and passive solar heating, ventilation of south facade, Trombe walls, reflective insulation, window and cover shadowing, mixed solar-biomass acclimatisation, full monitoring of building in order to achieve real time data transfer.

Keywords: Zero Energy Building (ZEB), Energy Efficiency in Edification

1. Introduction

Energy consumption in the housing and service sectors has great relevance in the ambit of the European Union, provided that it exceeds 40% of the total. All European countries have taken steps to restrict the energy demand (like for instance the new Royal Decree for the Technical Building Code — TBC — in Spain). Therefore, the application of sustainability criteria to building activity in order to favour energy collection is a priority task for public administrations.

Spain is the most energy consuming country in the European Union if referring to the tertiary sector. It has also the greatest potential for harnessing renewable energy sources.

The use of bioclimatic architecture is far from being a modern technique: caves and most traditional constructions are based on bioclimatic principles. However, bioclimatic buildings are an unusual type of housing at present. Although there is no specific official registry, it is estimated that there are between 5000 and 10000 buildings of this type in Spain, according to the Centre for Energetic, Environmental and Technological Research (CIEMAT).

Unfortunately, many housing projects are promoted nowadays as bioclimatic, although they should not be taken as such. To what extent should a building be considered to be bioclimatic? Such a denomination is wrongly being assigned to buildings that have a single eave as passive shading element and that integrate certain renewable energy devices.

It is important to note that the concept of bioclimatic construction might be seen as new from a textual point of view, but it is not as the constructive concept itself. Yet the Romans designed ventilated covers, and the Arabs invented the tile, the courtyards with ponds and convective loops, and inside gardened zones. In this sense, let us cite some examples like the ventilated adobe walls

in centenary constructions of Marrakech, or the efficient cow-dung huts of the Nubis people in the High Nile.

There are some projects being undertaken both inside and outside Spain which are similar to that proposed in the present communication. Some of the most relevant are the following:

• Sustenergy [1]. It was supported by the INTERREG III C Program, and ended in 2007. Six different institutions took part in this project, and was led by the Centre of Environmental Resources of Navarra (CRAN). The main goal was the development of common technologies in order to achieve energy saving and efficiency strategies in construction. One of the actions promoted was the set up of thirty pilot experiences, among which the Program for Efficiency in Construction was the most relevant.

• PSE-ARFRISOL [2]. Bioclimatic architecture and solar cooling. It is a Singular and Strategic project included in the National Plan of MEC and led by the CIEMAT. It is developed by twelve institutions, like solar energy technology companies and research groups from different universities and from the CIEMAT itself.

• Project CONAMA VII. It was presented in the Sustainable Development Conference held in November 25th 2004, in connection with the topic of Ecoefficiency in Construction. This project allowed to carry out detailed studies on the evaluation of the environmental behaviour of several buildings in Spain.

• Contest of ideas for the construction of a rural house in Chile, according to the principles of sustainability and energy saving [3].

• Cities for a More Sustainable Future [4], which can be looked up at the website of the Department of Urban and Landscape Planning in the Superior Technical School of Architecture (Polytechnic University, Madrid).

• Agenda for Sustainable Construction, a website designed by the Official College of Master Builders and Technical Architects of Barcelona, the Superior Technical School of Architecture of Valles, the Association for Geobiological Studies and the Cerda Institute.

• New York’s Department of Design and Construction. Office for Sustainable Design. This website is specialised in resources for sustainable construction, and is organised in six categories: projects, local legislation, reports and manuals, specification documents, pilot projects and reference examples.

• Website of the Official College of Architects of Cataluna [5], devoted to the Environment in the ambit of sustainable construction.

• CIEMAT, a technology centre linked to the Ministry of Education and Science devoted to promote Research-and-Development projects in the fields of energy (energy use of conventional and alternative sources), of environment (impact of energy on population and environment), of radiation protection (control and surveillance of ionizing radiation generated at CIEMAT), of magnetic confinement fusion (study of the device Stellerator Heliac flexible TJ-II) and also on basic research.

• Project LIFE-EcoValle. Bioclimatic conditioning of the road C-91 of UE-1 in the outskirts of Vallecas, in collaboration with CIEMAT.

• Forum Barcelona, a recent project based on the recycling of urban land.

The present communication describes the development of a project for the construction of an intelligent zero-conventional-energy building (“bioclimatic”) in the Campus of the University of Extremadura. It is linked to the development of the Project PETER (Experimental Transborder Park on Renewable Energies), which involves the Spanish institutions University of Extremadura, Province Deputation of Badajoz, Government of Extremadura (General Direction of University and Technology, Regional Ministry of Economy, Commerce and Innovation), IDAE and CIEMAT, and the Portuguese institutions University of Evora, INETI and ADRAL. The project is being carried out under the auspices of the Program INTERREG III of the European Union.

![]() 1st International Congress on Heating, Cooling, and Buildings ■ 7th to 10th October, Lisbon — Portugal *

1st International Congress on Heating, Cooling, and Buildings ■ 7th to 10th October, Lisbon — Portugal *

This proposal corresponds to what is referred to as sustainable edification, which includes actions in three different aspects: economic, environmental and social, and can be regarded as the continuation of other previous works performed by the research group DTERMA, from the University of Extremadura [7-9].

The main goal of the project described here are:

• To put in practice the concepts of energy saving and efficiency for the energy transformation devices relating different sources, energy storage, environmental impact, etc.

• To carry out a comparative empirical analysis among different energy sources, in order to emphasise the advantages of renewable versus conventional energy sources.

Joao Mariz Graga1 and Susana Andrade2

1 INETI — Instituto Nacional de Engenharia, Tecnologia e Inovagao;

Estrada do Pago do Lumiar, 22, 1649-038 Lisboa

2 Universidade Lusiada de Lisboa,

Rua da Junqueira, 188 — 198, 1349-001 Lisboa

Santana is a rural village in the north side of Madeira Island. Santana vernacular houses are quite typical in terms of their architectural image, but they also offer hight levels of comfort to their inhabitants. The climate of Madeira Island is mainly influenced by the Sea, so it is charaterised by the occurance of frequent low daily thermal amplitudes and by temperatures values near the comfort levels. However, since the altitude of Santana is near 500m from the sea level and this village is settled in the North side of the island, some cooling effects drive to lower temperatures than it can occur in other places of this island. Its is also not frequent that direct solar radiation reach the windows of these buildings, since the mountains of the island shade, long hours of the diurnal period, the path of the sun. This occurs particularly in winter time when the altitude angle of the sun is much lower. Another important feature is the frequently occurrence of cloudy sky which also reduces the solar gains in winter.

With the aim of extracting rules to apply in the design of passive houses to be built in this particularly region, and to validate the energy efficiency of this traditional constructions and architecture, some simulations have been done with the energy plus simulation program. This program provides the facility of extracting comfort reports based on the Fanger equation of comfort (ISO 7730), which can give to the architect a precise idea of the performance of the building without the need of consumption reports, which generaly greatly depend on the efficciency of the machines within the building. A validation with the portuguese thermal codes was also done, with the aim of finding the requirements for the construction that should be implemented in new buildings.

The simulations with energy plus have shown that the comfort could be easly achieved without the need of special active systems. This can be explained by the hight levels of insulation that are present in this construction (particularly in the roof) and by the maritime type of climate.

For improved energy efficiency the building shape will have a high compactness (small form factor) to minimize heat losses/gains through its envelope therefore reducing the heating and cooling demand.

Windows should be oriented south to optimize solar gains in winter period. In some climates the penalization is inferior towards west as a result of high temperatures and a higher probability of clear skies in the afternoon. In northern climates of Europe windows should face within 30° due south for solar gain design.[11] In the central area they may face within 40° and in the southern Europe within 50° due south. Northern windows should be restricted to minimum areas to prevent excessive heat losses. Nevertheless they should allow acceptable levels of daylight for visual performance and minimize energy consumption for lighting. All strategies adopted should take into consideration the local climatic conditions as well as the site layout.

Building shading may be a result of the building itself, external obstructions and shading devices. Appropriate solar control should be planned to avoid overheating of the adjacent spaces during the hot period. Overhangs are good systems to obtain a good solar control in south oriented surfaces. Because the solar altitude is lower on east and west orientations solar control is more complicated. Vertical fins and movable devices apply. Whenever possible, exterior shading devices should be used to prevent heat gains entering the space.