Как выбрать гостиницу для кошек

14 декабря, 2021

In the bicycle market, battery powered lighting is more and more common. A disadvantage of battery powered lighting is that the battery has to be replaced frequently. This can be avoided by using PV solar energy. The battery will then recharge itself and battery replacement is only necessary when the battery is worn out, after 3 to 4 years. The bicycle light designed in this project

makes use of a separable battery pack. The battery pack houses the PV panel and the battery, which means that it can charge separate from the bicycle on a location with higher irradiance than where the bicycle is parked. An additional advantage of the battery pack is that it can be used for other applications. Conversations with bicycle light manufacturers indicated that they are interested in designing bicycle lights that make use of the battery pack.

|

Fig. 7. PV battery pack in the bicycle light (left) and the battery pack (right) |

Actually, there are two major problems we could see in our projects. The first one is related to the interface to the distribution of chilled water in the buildings. Quite often flow of distribution is not balanced and optimized, return temperatures are very low and need careful evaluation already in the engineering but affect significantly operation. Otherwise the absorbtion chiller runs in modes very close to freezing temperatures that possibly can affect the chiller, however, adjusting existing systems can be a serious challenge.

Second, we can report some problems with the cooling towers that are not specifically connected to the solar system but typical for open cooling towers. Blocked flow and insufficient water supply caused a stop of a system several times.

Besides that, the systems are very stable and could overcome blackouts and other human impacts surprisingly easy.

In this work only thermal solar systems which are pre-heat or solar only systems for preparation of hot water are considered, since this is the case where the Portuguese regulations [1] imposes a specific calculation methodology [2].

1.1 European Standard EN 15316 (part 4-3) Methodology

The objective of this series of European Standards is the calculation of system energy requirements and system efficiencies. According to the standard, for thermal solar systems, the heat balance corresponds to the schematic representation of Fig.1 (for pre-heat/solar only systems). In this figured the terms relevant for comparison with SolTerm [2] are signalled in red. Only hot water preparation is relevant for this purpose. The input, Esolin, for purposes of comparison, was determined by the SolTerm data base.

|

In this short description, the nomenclature of the standard will be used. In some situations, clarification of the terms is need since they do not correspond to the common solar thermal vocabulary according to EN ISO 9488 [4]. This is the case of the term “auxiliary”, which the standard uses for the electrical energy for pumps and controllers and for which the Solar Energy Vocabulary (EN ISO 9488) [4] uses the term “parasitic energy”.

The main objective of the standard EN 15326-4-3 [3] is the calculation QHW, sol, out, i. e., the total heat delivered by the thermal solar system to space heating and domestic hot water distribution system. As already stated, the present discussion will be centred on the calculation of QW, sol, out . Two methods are considered for this calculation:

— Method A uses the results of tests performed to Factory Made Systems according to EN 12976-2

[5] .

— Method B uses as input data the solar thermal system component data, i. e. system dimensional characteristics and data from component test and state of the art knowledge, such as:

Collector parameters: collector aperture area, zero-loss efficiency, heat loss coefficients;

Collector loop thermal losses and thermal losses of the distribution between storage tank and the distribution system (length of pipes, insulation and efficiency);

Climatic conditions: solar irradiation, outdoor air temperature;

Thermal losses of the solar storage tank

Storage tank parameters: type of storage tank, size;

In this paper all comparisons are performed considering the method B, based on the f-chart method

[6] . The general calculation of solar output is given by the expression:

=(a + bX + cY2 + dX2 + e¥3)-о, Лш„ [KWh] (1)

Where Qsolusm is the monthly heat use applied to the thermal solar system [kWh], usually termed

as heat demand. a, b, c, d, e are correlation factors depending on system configuration[8] and X and Y are dimensionless factors.

The term Qsohout, m represents the monthly values of QW solout For the determination of X the following equation is used:

X = A ■ Uloop ■ Л loop ■ AT ■ fst ■ tm /(Qsol, us, m ‘ 1000) (2)

In this expression of X, the term AT is a reference temperature difference calculated according to:

AT = Є„, — Q. ae [K] (3)

The heat loss coefficient of the collector loop, i. e., collectors and pipes, is determined by the collector characteristics and the insulation of the pipes. The heat loss loop coefficient is calculated by:

Uio0p = a1 + a ■ 40 + Ul0op, p / A [W/(m2.K)] (4)

The value Y is calculated according to eq. 5. It depends on the collector data (zero-loss collector efficiency) and the solar irradiance on the collector plane:

Y = A ■ IAM ■ Ло • Aioop ■ Im ■ tm /feoum •1000)

The term Qsoi, us, m is calculated considering the daily load volume, a fixed load temperature and a fixed cold water temperature:

Qsol, us, m Vload’P’Cp'(Tload (6) with p=1kg/litre and Cp = 4187 kJ/kg°C.

For some of the above parameters, the standard suggests default values. The values considered in the comparison were chosen either in accordance with the default values of EN 15316-4-3 or with those considered in SolTerm [2]. For determination of the thermal solar system output, care has to be taken in order to consider only Qsol, out, m < Qsol, use, m and Qsol, out, m > 0.

L. Brotas1, G. Carrilho da Gra^a2, H. Gonsalves1*, M. Lerer2 and P. Paredes2

1 INETI, Department of Renewable Energy, Campus do Lumiar do INETI, 1649-038 Lisbon, Portugal

2 Natural Works, Rua Ricardo Espnito Santo N7 CV-E, 1200-790 Lisbon, Portugal

* Corresponding Author, helder. goncalves@ineti. pt

Achieving a pleasant indoor environment with low energy consumption is a major goal of good building design. Overheating, in particular, is a problem in southern European climates, where several approaches to achieving comfortable indoor conditions, while keeping the building’s energy consumption low, have been successfully established. The Passivhaus standard, developed in Germany, defines requirements for very-low energy homes with regards to space heating. The strategies adopted in cold climates consist of a highly insulated envelope combined with reduced air losses and a mechanical ventilation system with heat recovery. This approach reduces the heating needs and high thermal comfort levels can be achieved with improved energy efficiency. The Passive-On project has taken this concept further by also looking at the warmer European climates where the cooling loads may become a major issue. The project consortium has therefore formulated a revised proposal for the application of the standard to those climates. This paper presents part of the results of this European funded project.

Keywords: Low energy buildings, Passivhaus, passive cooling, adaptive comfort

In Europe, buildings are responsible for 40% of the final energy consumed. In Portugal, this percentage is lower, 17% domestic and 12% services (2006). However, the energy consumption is still increasing, in particular related to cooling systems. Within this context, the European Commission presented the directive EPBD which focused on the energy performance in buildings. Moreover, recent concerns about the security of the energy supply and the rising price of oil, make energy efficiency a top priority, as well as to diversify the energetic resources, promoting the adoption of renewable energies to reduce the exterior energy dependency and GEE emissions. [1]

More broadly, the European Parliament resolution of 31 January 2008 on an Action Plan for Energy Efficiency: Realising the Potential “calls on the Commission to propose a binding requirement that all new buildings needing to be heated and/or cooled be constructed to passive house or equivalent non-residential standards from 2011 onwards, and a requirement to use passive heating and cooling solutions from 2008”. [2]

Other countries of Europe have standards such as the Code of Sustainable Homes in England and Wales where level 5 corresponds to the Passivhaus standard, to be enforced by 1912. This standard also requires all homes to be zero carbon (level 6) by 2016, having to produce on-site energy. [3]

Figure 4 presents the results of the lighting index for different d/h ratio and for two different opening azimuths. d represents the length of the overhang and h the height of the window. These values of Cm are also compared to the PERENE requirements.

One can notice that the objectives of PERENE are too difficult to meet. We have assumed that the glazing has a transmittance equal to 1 (the window is opened if it is used in natural ventilation). PERENE requires values of Cm of 0,3 and 0,25 for windows facing North and West respectively.

Values of Cm of 0,3 and 0,5 are respectively demanded for openings oriented East and South. Only a d/h ratio of 1.5 could allow to meet PERENE for an East-oriented window.

To meet acceptable values of Cm, it would be necessary to reduce the transmittance of the glazing, what is not possible if this one is used in natural ventilation. It would be necessary to reconsider the requirements of the PERENE standard, at least for this type of solar shading

|

Figure 4: Values of lighting index Cm for different d/h ratio and for North and West oriented windows. d represents the length of the overhang and h the height of the window |

|

Figure 5: Values of lighting index Cm for different d/h ratio and for East and South oriented windows. d represents the length of the overhang and h the height of the window |

XP. Haugaard, 2D. Aara, 3P. Poulsen, 3B. Bentzen, P., 4P. M. Nielsen and 4J. Andersen

1 Esbensen Consulting Engineers A/S, Gammel Koge Landevej 22, 2500 Valby, Denmark

2 Gaia Solar A/S, Hammerholmen 9-13, 2650 Hvidovre, Denmark

3 FAKTOR 3 ApS, Vesterbrogade 24b 2. sal, 1620 Kobenhavn V, Denmark

4 Idealcombi A/S, Norre Alle 51, 7760 Hump, Denmark

* Corresponding Author, p. haugaard@esbensen. dk

The project group is developing a low-cost PV-window for building owners and architects to use in building designs for both new and retrofit buildings. With a U-value of 1.20 W/m2K the developed PV-window fulfills the requirements within the Danish Building Regulation and as a bonus it produces electricity to the building.

Architects have found the PV-window interesting to use in building designs hence it offer many different possibilities to regulate the thermal indoor climate, daylight penetrations, reflections and communications. Tests have shown, depending on the design and layout of the PV-pane, that the PV-window can supply sufficient daylight to buildings.

The PV-window addresses the field of making energy right buildings using the energy falling on the buildings to supply itself in a fully integrated an aesthetical way and not as an add-on to buildings. It helps reducing the need for primary energy and gives the building a clearly environmentally green profile.

The development of this product has not been completed and will continue.

Keywords: PV-window, Building Regulation, low cost, custom design

1. Introduction

From the proactive strategy of reducing prices on integrated PV-systems the project aims to develop a PV-window which is cheaper than and technical fully compatible with the existing relative expensive standard PV-panels. Hence it is also the aim to develop an elegant PV-window solution that integrates architecture, aesthetics and flexibility in its design thus becoming an elegant attractive solution for both new and retrofit buildings. The PV-window must apply to the current Building Regulations in Denmark which has been tightened in 2006.

It is the objective to reduce the price on the PV-window by up till 20 % or more compared to similar products, fulfill the Danish Building Regulation, integrate, demonstrate and test the PV- window in an actual building and learn how it influences on thermal indoor climate in spaces.

The project is a part of the Danish PSO-F&U scheme sponsored by Energinet. dk.

2.1. Results of Winter Shading Simulation Profiles

The results from computer building simulations, of various shading profiles caused by unexpected occupant intervention with the solar aperture, other than the one specified for the “Zero Energy House”, are analysed and assessed having as basis the optimum fenestration shading strategy for winter as defined below.

a) Optimised Fenestration Shading Strategy for Winter

The optimized fenestration strategy for winter from the previous research study “Shading” [1] is outlined as having all glazed area unshaded during the day time to obtain maximum solar gains and achieve comfort indoor conditions in the range of 18.6 — 20.6 degrees Centigrade (Table 1, 1.0).

b) North Window Shutters Shaded

If North window shutters (Area=3.5m2) are left closed during the day in winter, the indoor temperature reduces by 0.1 to 0.2 degrees Centigrade (Table 1, 1.1) i. e. 1% to 1.5% departure from the temperature achieved in the optimized fenestration profile (Table 1, 1.0). However the indoor temperature is maintained within the comfort range for winter (18.6-22.6 deg. Celsius).

c) North and West Window Shutters Shaded

When in addition to North window shutters, the West ones are left closed during winter days, an insignificant temperature of further reduction of 0.1 degrees Centigrade occurs, and that only at certain hours of the day no obvious pattern (Table 1, 1.2). The small extent of temperature reduction is attributed to:

i) Orientation — West orientated windows have no direct solar gains in winter.

ii) Window Area — The west window area amounts only to 0.50m2. The indoor temperature is maintained within comfort levels.

d) North, West and Half South window Shutters Shaded

When in addition to North and West window shutters half South window area remains shaded during the day, an indoor temperature reduction of 4.0 to 5.0 degrees Centigrade incurs i. e. 23% to 30%. This temperature drop lowers the indoor temperature below comfort level by 2.0 to 5.2 degrees Centigrade (Table1, 1.3). The largest drop, of 5.2 degrees Centigrade, occurs between

09.0 to 22.00 hours. This span of time is that receiving the most of direct solar gain followed by six hours in the evening, as the result of time lag. The rapid reduction of indoor temperature is expected due to:

i) Orientation. South facing windows invite amounts of solar gains incident at small angles in winter. Thus interception of solar radiation on this orientation has direct effect on indoor temperature.

ii) Window Area. The south glazing area with solar aperture is limited by 17.5m2 which is a considerable amount of glazing reduction and consequently solar gains.

e) All Windows Shaded

When all windows remain shaded during winter days, indoor temperature decreases in the rate of

9.0 to 10.5 degrees Celsius (Table 1, 1.4). The additional shaded window area is of equal (17.50m2) as in the previous shading window profile above (Table 1, 1.3) however the indoor temperature reduction in current profile is 1.0 degree more. This is expected as all glazed area is shaded and there is no solar access at all. The indoor temperature drops further by 4.0 degrees to its lowest levels which at certain hours (09.00 to 18.00) is even lower than outdoor temperature (Table 1, 1.4).

The performance results show that amorphous silicon modules installed in the park have an average performance ratio of 0.76 and the multicrystalline modules installed in the facade have a value of 0.84, due mainly to lower average irradiance values leading also to lower average working temperatures.

|

Table 7. Yearly performance ratio averages in the PV Facade and PV Park systems.

|

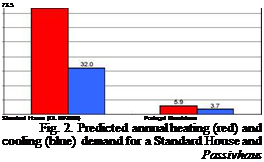

The annual heating energy demand of the Passivhaus proposed for Portugal has been estimated as 16.9 kWh/m2, of which 11 kWh/m2 are supplied by the solar system (in this analysis priority of the solar system is given to heating and the solar fraction for domestic hot water is 48%). The annual cooling energy demand is 3.7 kWh/m2. The sum of net heating and cooling demand is

9.6 kWh/m2/yr. According to the thermal regulation, the limits of heating and cooling for this house built in Lisbon are 73.5 and 32 kWh/m2/yr, respectively. See fig. 2.

80 70 60 50 40 30 20 10 0

80 70 60 50 40 30 20 10 0

The analysis of the thermal comfort is based on the resultant (or operative) temperature, which is the average between air and radiant temperature. The comfort criteria adopted during the summer analysis were based on the calculation of comfort indexes. [6]

This prototype, with an active cooling, has a Fanger Comfort Index of 811 (the house is penalized by the influence of the high glazed area on the radiant temperature). If no active cooling is present, the Adaptive Comfort Index (AI2) applies and is 16. The resultant temperature is kept below 25°C for 71% of the occupied time, and below 28 °C during 98% of the occupied time. To reduce overheating the size of the windows and the thermal insulation should be reduced (though this increases the heating demand). See fig. 3 for the simulated distribution of the indoor and outdoor temperatures in a hot summer week with the Lisbon’s weather file. In winter, the low-power heating system of 10 W/m2 is in use, resulting in only 8% of time with a resultant temperature below 19.5°C (the lower temperature achieved is 18°C). Indoor temperatures show a reduce variation especially in comparison to the outdoor temperature fluctuation.

|

External Dry Bulb Temperature Indoor Resultant Temperature

Fig. 3. Indoor and outdoor temperatures during a very hot week, without active cooling, in Lisbon. |

The two Portuguese partners would like to acknowledge the remaining partners and subcontractors of the project and the EC financial support for the work developed within the project Passive-On (‘Marketable Passive Homes for Winter and Summer Comfort’ EIE/04/091/S07.38644, 2004-‘07).

Clearly, there is a trend to move towards low energy buildings with comfortable indoor conditions and the Passivhaus standard may be an economically feasible solution to achieve those aims. A discussion is raised whether there is the necessity to create airtight buildings with heat recovery mechanical ventilation. In relatively mild climates of Europe where many people still routinely sleep with their windows open, the adoption of a mechanical enforced ventilation system may be compromised. Strategies that combine natural ventilation, solar control and high thermal inertia have been accepted as possible solutions to implement in places with climate conditions similar to those studied within this project. A set of preferred passive/hybrid systems which allow the energy limit and the quality requirement to be met cost-effectively were also defined. An effective solar control and a night ventilation strategy, which dissipates solar and internal gains, can reduce the power of the active cooling system or make its installation unnecessary.

Previous analysis shows how the strategies adopted for the design of a Passivhaus for the heating and cooling climate of Lisbon can be successful, both regarding the energy demand limits and the comfort levels requirements. Although the specific design may be very different from the simple layout presented, the applied strategies have proven effective in reducing energy consumption.

[1] Directive 2002/91/CE of the European Parliament and of the Council of December 16 2002 on the energy performance of buildings, Official Journal L 001 of 04/01/2003 p 0065-0071;

[2] Action Plan for Energy Efficiency: Realising the Potential, INI/2007/2106: 31/01/2008 — EP: non-legislative resolution;

[3] Code for Sustainable Homes: Technical Guide, Department for Communities and Local Government, April 2008;

[4] Nicol, F. and McCartney, K. (2001) Smart Controls and Thermal Comfort (SCATs), final report to the European Commission (Contract JOE3-CT97-0066) Oxford Brookes University.

[5] Humphreys, M. A. and Nicol, J. F. (1998) Understanding the Adaptive Approach to Thermal Comfort, ASHRAE Technical Data Bulletin Vol. 14 (1) Field studies of thermal comfort and adaptation (ed. Geschwiler M et al) American Society of Heating Refrigeration and AirConditioning Engineers, Atlanta, USA 1998

[6] The Passivhaus standard in European Warm Climates: Design Guidelines for Comfortable Low Energy Homes: Part 2. National proposals in detail: Passivhaus Portugal and Part 3. Comfort, climate and passive strategies, both Edited and compiled by: Brian Ford, Rosa Schiano-Phan and Duan Zhongcheng, School of the Built Environment, University of Nottingham. Download at: http://www. passive-on. org/en/cd. php (accessed Aug 2008).

Operating Agent for IEA SHC Task 37

KanEnergi AS, Hoffsveien 13, 0275 Oslo, Norway

This paper gives an overview presentation of the IEA SHC task 37 “Advanced Housing Renovation by Solar & Conservation”. The task is organized under the IEA Solar Heating and Cooling Programme (SHC) and includes more than 40 experts from 12 countries. The task started in 2006 and will end in December 2009.

The objective of this Task is to develop a solid knowledge base how to renovate housing to a very high energy standard while providing superior comfort and sustainability. The task will also develop strategies which support market penetration of such renovations explicitly directed towards market segments with high renovation and multipliable potentials. The technical R&D and the market implementation activities are equal priority areas.

Keywords: Housing renovation, IEA SHC, EuroSun2008

1. Introduction

Buildings are responsible for up to 35 percent of the total energy consumption in many IEA countries. And, housing is the largest energy consumer in the building sector. When houses are renovated to meet contemporary expectations and lifestyles or to repair existing construction, there is the opportunity to reduce the building’s energy use often at marginal extra costs.

Many exemplary renovation projects have been completed, but the experience gained has not been systematically analyzed and many projects are at best only locally known. Because most property owners are not even aware how far energy demand can be economically reduced, they too often set mediocre goals. This is a missed opportunity to prepare buildings for the future energy era.

To address this void, the IEA SHC Programme’s Task 37: “Advanced Housing Renovation with Solar & Conservation” is working to develop a solid knowledge base on how to renovate houses to a very high energy standard and to develop strategies that support the market penetration of these renovations. SHC Task 37 is analyzing and will publicize the results of many successful renovation projects. Based on this analysis, innovative concepts will be identified and further developed for the most important housing market segments. The global environmental impact of such solutions will also be examined.

To address this void, the IEA SHC Programme’s Task 37: “Advanced Housing Renovation with Solar & Conservation” is working to develop a solid knowledge base on how to renovate houses to a very high energy standard and to develop strategies that support the market penetration of these renovations. SHC Task 37 is analyzing and will publicize the results of many successful renovation projects. Based on this analysis, innovative concepts will be identified and further developed for the most important housing market segments. The global environmental impact of such solutions will also be examined.

The Task started in July 2006 and will be finished by the end of 2009.

1

![]() The task has more than 40 experts from Austria, Belgium, Canada, Denmark, Finland, Germany, Italy, the Netherlands, Norway, New Zealand, Sweden and Switzerland.

The task has more than 40 experts from Austria, Belgium, Canada, Denmark, Finland, Germany, Italy, the Netherlands, Norway, New Zealand, Sweden and Switzerland.

The objective of the Task is to

• develop a solid knowledge base how to renovate housing to a very high energy standard while providing superior comfort and sustainability

• develop strategies which support market penetration of such renovations explicitly directed towards market segments with high renovation and multipliable potentials

The technical R&D and the market implementation activities are equal priority areas.

2. Status and results

The work is organized in four subtasks, and a short description and status is presented below

A. Marketing and Communication Strategies

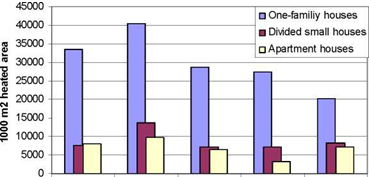

This Subtask is analyzing the building stock in order to identify building segments with the greatest multiplication and energy saving potential. Examples of building segments are year of construction, type of buildings, type of envelope and components. Within these segments important topics for discussions are: — ownership and decision structures, inhabitants and their characteristics and actual groups of retrofit market players.

|

Building stock analysis has been completed in several countries and these will be the basis for a cross country summary report. In parallel the experts are working on the content of the coming report “Business Opportunities in Advanced Renovation”.

Figure 1 Example from the building stock analyses in Norway

The analysis of successful renovation projects is underway and experts have agreed upon a set of criteria for selecting demonstration projects.

10th October, Lisbon — Portugal *

|

Occupancy types: |

All forms of housing including mix uses |

|

Concept: |

Something innovative enough for international publication. |

|

Energy: |

Max primary energy for space heating and associated technical installations (fans, pumps, etc.): 60 kWh/m2. Opaque envelope insulation < 0,25 W/m2K (if possible, should not exclude special buildings, for example, historical buildings). |

|

Economics: |

Marketable solutions |

|

Design: |

Substantial improved living quality. |

|

Table 1: Criteria for selecting demonstration projects |

|

Several exemplary renovation projects have be selected from most of the participating countries. A standard reporting format and units are used to allow cross comparisons. The objective is to characterize the renovation process, motivations, benefits and opportunities for improvement.

Figure 2 Example brochures of exemplary buildings

A number of brochures are available from the task 37 web-site www. iea-shc. org/task37

These brochures show a dramatic reduction in the demand for heat, up to 95%. Twelve task 37 demo-projects show energy reductions from 62 to 95%, with the average 75%.

Drawing on the market analyses for subtask A and the exemplary projects from subtask B, in this subtask concept packages will be identified and analysed to maximize their life cycle benefit/cost ration. The work will draw on simulations, monitoring of in-place applications and feedback from the industry. Details of solutions, design advice and examples of phased, compatible renovation measures will be reported.

The experts are working on different aspects, and among these are

• whole building concepts

• thermal bridge recommendations

• monitoring of built housing renovations

D. Environmental Impact Assessment

In subtask D the environmental impacts of a sample of renovation projects will be assessed.

In subtask D the environmental impacts of a sample of renovation projects will be assessed.

Factors such as: CO2, water, waste, materials flow, use of urban space and health as well as social consequences will be considered. Life cycle analyses will be carried out in the full range of scales from components to urban neighborhoods.

Subtask D will produce a booklet on Sustainable Renovation Basics. The draft report is expected to be ready by this autumn.