Как выбрать гостиницу для кошек

14 декабря, 2021

|

Shading of faqade solar collectors has been investigated for two basic block of flats types usual in urban housing estates: row buildings and tower buildings. Shading analysis has been performed in simulation software ESP-r, which allows energy balances including the shading by surrounding objects (isotropic radiation model used). Climatic database for Prague (Czech Republic) in the form of test reference year has been used as a source of solar irradiation data. Albedo of the terrain surface has been considered 0.2. Annual solar irradiation qs [kWh/m2.a] of south oriented faqade located at shaded object has been obtained from simulations in dependence on distance and height of surrounding shading objects. Annual solar irradiation of faqade without any shading (maximum value) is qs = 749 kWh/m2.a for given climatic database.

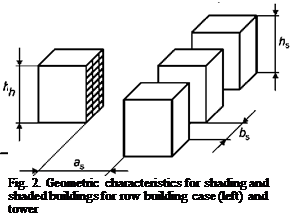

For the row building, the building with the same ground plan (length 50 m, width 10 m) has been considered as the shading object. Distance as [m] and height of shading building hs [m] with respect to height of shaded building h [m] were the variables. Simulation analysis has been performed with distance range from 3 to 50 m and buildings height range from 3 to 24 m (eight floor building). Geometry and parameters for the row building case are outlined in Fig. 2 (left).

Three shading objects with identical ground plan (20 x 20 m) as the shaded one have been considered in the tower building case. Height of both shaded and shading buildings has been used equal and varied from 3 to 24 m. Distance as of shading objects from shaded one and mutual distance between shading objects bs were the variables and both ranged from 3 to 50 m. Geometry and parameters for the tower building case are outlined in Fig. 2 (right).

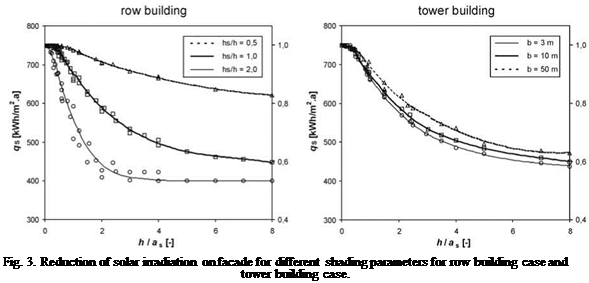

Shading of row building in housing estate has been modelled for large number of relationships between shaded and shading buildings in distance and height values. Annual irradiation levels incident on the south facade qs [kWh/m2] dependent on ratio of shaded building height h and its distance as from shading building with the height hs have been obtained. Three sets of results represent different height ratio hs/h between shading and shaded building. Fig. 3 (left) shows the dependence of facade irradiation qs and its percentual reduction on h/as ratio for different height parameter hs/h (values 0.5; 1.0; 2.0). It is evident that influence of shading can be neglected for low values of h/as < 0.5, eventually for low values of hs/h < 0.5.

Shading of tower building in the housing estate has been modelled in similar way to row building case. The ratio between shading and shaded building hs/h =1 has been considered. Besides the influence of distance as between shading buildings and shaded building the influence of mutual distance bs between shading buildings has been investigated. Three sets of results have been obtained for different distance bs values (3; 10; 50 m). Curves qs = f (h/as) are shown in Fig. 3 (right) together with percentual reduction figures. Similar to row building case, influence of shading can be neglected for low values of h/as < 0.5. Shape of curves for different distance bs values are not changing significantly.

Wildor Maldonado Carbajal

Manuel Collares Pereira

Ao Sol Energias Renovaveis S. A., Parque Industrial de Porto Alto, Sesmaria Limpa, Samora Correia,

Portugal, +351263 65 13 05/06,

wildormaldonado@aosol. pt; mpicp@aosol. pt

Abstract

The integration of solar collectors on building facades is becoming a much more common option, and a true alternative to the usual placement of collectors on terraces or on roofs, seeking an orientation towards azimuth south (on the northern hemisphere) and a tilt equal or higher than latitude.

For a stationary collector the choice of azimuth south and a tilt around the value of latitude maximizes yearly energy collection, or Winter energy collection, when a tilt value higher than that of local latitude is chosen.

However when collectors have to go on a vertical faqade the results obtained are much different, specially on latitudes typical of southern Europe, i. e. from 35° to 55°; from winter to summer, due-south may no longer be the azimuth of choice. In fact, in the summer time, the sun is “very high” in the sky and is basically reflected off the collector glass cover, greatly reducing the collected radiation.

In this paper the authors wish to make a collector performance evaluation of three different collectors, operating on vertical surfaces. The three collector types are a flat plate collector and two CPC collectors, one with absorber fins running horizontally (HF) and another with the absorber fins running vertically (VF). The comparison will be made at constant inlet temperature to the collectors. The flat plate collector is a good selective surface one and the CPCs chosen are: (i) a standard CPC manufactured by AO SOL for the VF case and (ii) a new proposed design for the HF case.

This HF case is an attempt at having an optics developed to somehow compensate the grazing incidence angles of the sun in the summertime, when the sun is highest in the sky and the azimuth of the vertical wall approaches zero (due-south).

For faqade azimuth varying between 0° to 90° we calculate the solar energy collected (direct and diffuse radiation) for apparent solar annual motion, and use recent refinements proposed to standard calculation methods [1,2]. A comparison will also be made with the same collectors operating according to the usual “due south-tilt equal latitude” procedure.

The analysis is done for two locations Lisbon (latitude 38.75°) and Freiburg (latitude 48°) as two representative cases.

The results show that the behaviour of the collectors on vertical walls is more or less the same on an yearly basis for several different azimuths, (a result which was not intuitive to the authors) although they are quite different on a seasonal basis.

As for the comparison between the three collectors considered it is seen that the CPC HF is better than the other two, in particular for azimuths closer to zero, both because of its optical behaviour and because of its better thermal performance.

1. Introduction

The integration of solar collectors on building facades is becoming a much more common option, and a true alternative to the usual placement of collectors on terraces or on roofs, with an orientation towards azimuth south (on the northern hemisphere) and a tilt equal or higher than latitude.

In this paper the authors wish to make a collector performance evaluation of three different collectors, operating on vertical surfaces, with different azimuths. The three collector types are a flat plate collector and two CPC collectors, one with absorber fins running horizontally (HF) and another with the absorber fins running vertically (VF). The comparison will be made at constant inlet temperature to the collectors. The flat plate collector is a good selective surface one and the CPCs chosen are: (i) a standard CPC manufactured by AO SOL for the VF case and (ii) a new proposed design for the HF case.

This HF case is an attempt at having an optics developed to somehow compensate the grazing incidence angles of the sun in the summertime, when the sun is highest in the sky and the azimuth of the vertical wall approaches zero (due-south).

The relevant characteristics of all collectors are presented in chapter 2. and their performance is calculated (at constant inlet temperature) in chapter 4 for the following situations:

1) Yearly performance for the 5 azimuths 0, 22.5, 45, 67.5 and 90 deg.

2) Comparison of the values obtained for azimuth zero, with what would be obtained if the collectors were operated at tilt-equal latitude.

3) Monthly performances at Tin = 40°C, for the same azimuths as in 1).

The paper ends (chapter 4) with a summary of the main conclusions.

2. Collector description

Table 1 summarizes the optical and thermal characteristics of the collectors chosen for this study.

|

Table 1. Involved Collectors.

|

All collectors are characterized in the so called linear approximation, with a coefficient describing its optical efficiency (F’q0) measured at normal incidence and another (F’UL) its heat loss.

The flat plate is taken as a standard good selective coated one. The two CPCs used in this study are:

|

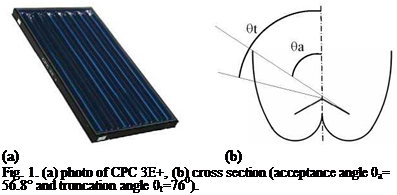

1) VF CPC — standard 3E+ CPC manufactured by AO SOL Energias Renovaveis S. A. [3], as in Fig. 1, with an effective concentration of 1.15X, after truncation.

|

|

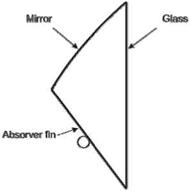

2) HF CPC — a collector with the cross section of Fig. 2 is considered. Its final concentration is 1.5X, a CPC with a full acceptance angle of 110° deg. Notice the asymmetric nature of this collector, expressly conceived so that the fin has a tilt with respect to the entrance aperture (the vertical glass cover) of 20° deg. This tilt is not the yet the result of an optimization, but it is a first attempt at reducing on average, incidence angles on the absorber.

(a)

Fig. 2. HF CPC: (a) cross section, (b) on a vertical wall.

This collector has not yet been built and its performance is extrapolated from the one obtained at AO SOL with a symmetric collector with a similar concentration value [8].

Calculation of collector thermal performance at different inlet temperatures is made with a standard utilizability [4] based method. The optical performance is calculated taking into account the corrections and the methodology described in [1, 2], corrections arising from the fact that standard efficiency tests were not designed for CPC collectors.

The proper incidence angle modifiers in each case (longitudinal and transversal), evaluated through detailed ray tracing is used, as well as the behaviour with respect to diffuse radiation.

All calculations are done for two cities: Lisbon with a latitude of 39° deg and Freiburg with a latitude of 48° deg.

3. Results

3.1- yearly performance evaluation at five different azimuths

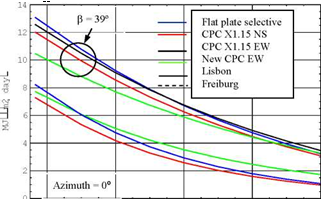

The three collectors are placed vertically and their performance is evaluated for the following azimuths: 0°, 22.5°, 45°, 67.5° and 90°. These are taken from South (0°) to West (90°) assuming that towards the East the behaviour is identical (symmetrical).

|

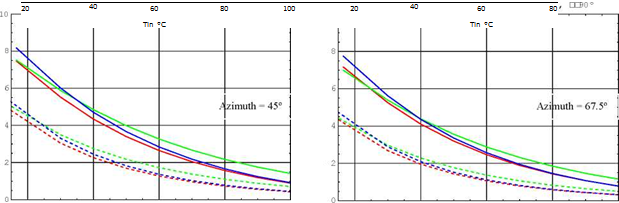

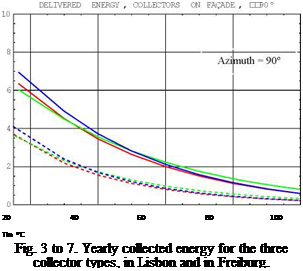

Fig. 3 to 7 show the yearly performance for each collector type, as a function of inlet temperature, at two different latitudes, that of Lisbon and that of Freiburg, and at azimuth zero (vertical due south).

|

The VF CPC is more optically penalized by the vertical wall than the flat plate, but the HF CPC has a better behaviour resulting for an acceptance angle more favourably defined with respect to collector orientation vs. apparent motion of the sun.

A striking observation — see Fig. 3 to 7- is that there is not much difference on yearly collected energy, even for walls with very large deviations from zero azimuth!.

This non intuitive result will be explained in the coming sections, once the monthly behaviour is presented.

Fig. 8, 9 are a reproductions of Fig. 3, with the addition of the results [2] of the calculation of energy delivered at tilt equal latitude and the same azimuth, to give an idea of the penalty introduced by the unfavourable vertical wall (tilt equal 90° deg).

It can be seen that the difference between the VF CPC and the flat plate is attenuated for tilt equal latitude (a tilt for which the CPC in question was designed).

The reverse is true for the HF CPC, now with not so good a behaviour in the tilt equal latitude mode, a logical consequence of the fact that it was designed for the vertical wall.

It can also be seen that in general there is a penalty on the order of a factor of two for the operating temperature range considered, for going on the vertical wall as opposed to working within the more favourable orientation.

The HF CPC was not meant to operate at tilt equal latitude and that shows in the poorer result obtained when that tilt is used in this case. This difference is still pronounced but less significant at the higher latitude (Freiburg).

|

|

Fig. 8. Comparison of yearly collected energy on the vertical wall and at tilt equal latitude in Lisbon, Fig. 9.

The same for Freiburg.

3.3- The seasonal behaviour of the collectors for the different azimuths

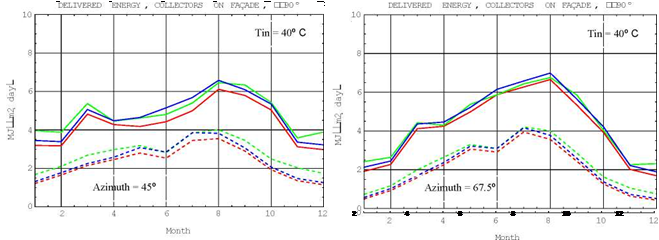

In this analysis only the performance at Tin = 40°C is presented, for the sake of space. Monthly energy delivered is presented for each azimuth and collector type.

|

It can be seen that the differences between winter and summer months are much larger for the wall facing south than for the others. In fact the intermediate azimuths show a more constant monthly performance. When totals are calculated this yields the results referred in 3.1.

4. Conclusions

Three collector types — a flat plate collector and two CPC type collectors — were placed on vertical walls and their performance evaluated at different temperatures, in two locations, Lisbon and Freiburg, respectively a lower and a middle latitude in Europe.

It was shown that this collector mounting yields significantly less energy than the usual tilt equal latitude, due south, collector orientation usually recommended. These differences are larger for Lisbon (almost a factor of two) than for Freiburg, at a higher latitude, thus with the sun on average more perpendicular to the vertical wall, all year round.

The results for annual energy yield on vertical walls for the three collector types, show that the behaviour (average energy delivered at constant operating temperature) of each of them is more or less insensitive to the direction the wall faces up to very large deviations (67.5° deg) from azimuth zero (a wall facing due south). This is a result which was not intuitive to the authors.

However on a monthly basis the differences are quite apparent, with the wall due south showing a larger winter time contribution and a larger difference between winter and summer months.

As for the relative yield of each collector type, the comparison shows that the CPC HF (a first and very simple attempt at designing a CPC to operate on vertical mounting) is better than the other two, in particular for azimuths closer to zero, both because of its optical behaviour and because of its better thermal performance, underlining the fact that it was really meant to operate on the vertical as the other two were not.

In the future, the wider use of solar energy to heat and cool buildings as well as to provide DHW, will require a much wider use of building facades to place solar collectors, quite beyond the usual placement on the roof. The kind of study presented here will certainly be made for new collectors,

meant to take the best advantage of the new 90° deg tilt, trying to reduce the penalties it imposes,

when compared to more usual tilt and orientations.

References

[1]Pedro Ribeiro Horta, MSc. Eng.; Maria J Carvalho, PhD; Manuel Collares-Pereira, PhD; Wildor Carbajal, Eng. — “Long term performance calculations based on steady state efficiency test results :analysis of optical effects affecting beam diffuse and reflected radiation” — submitted to Solar Energy Journal (2007).

[2]Manuel Collares-Pereira, PhD; Wildor Maldonado, Eng. — “Efficiency testing of solar collectors and long term performance simulation tools: application to flat plate and CPC type collectors”. ESTEC 2007.

[3]AOSOL, Energias Renovaveis S. A. is a company owned by a Portuguese investing holding group ENERPURA. It designs and supply thermal solar collectors of the CPC type. www. aosol. pt.

[4]Manuel Collares Pereira, Maria Joao Carvalho — “Dimensionamento de sistemas solares; sistemas de aquecimento de agua com aramazenamento acoplado”- Laboratorio Nacional de Engenharia e Tecnologia Industrial Industrial, Departamento de Energias Renovaveis (1990).

[5]Carvalho, M. J. et al 1987. Economic Optimization of Stationary Non evacuated CPC Solar Collectors. Journal of Solar Engineering vol. 109 pp.40-45.

[6]William R. Mclntire. 1982.”Factored approximations for biaxial incident angle modifiers”. Solar Energy, Vol. 29, N° 4, pp. 315-322, 1982. Pergamon Press Ltd.

[7]Ari Rabl. 1985. “Active Solar Collectors and Their Applications”. New York: Oxford University Press, Inc.

[8]M. Collares Pereira, M. J. Carvalho, J. Correia de Oliveira. "A new low concentration CPC type collector with convection controlled by a honeycomb TIM material: a compromise with stagnation temperature control and survival of cheap fabrication materials" ISES Solar World Congress, Goteborg, June, 2003.

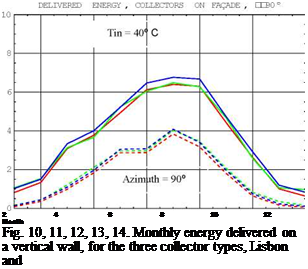

As explained in Section 3, the lighting problems that bother LESO-SEB occupants the most are due to daylight overprovision. It is therefore necessary to take a close look at the glare protection devices installed within the ADS-equipped office rooms, to identify their weak spots and to find ways to optimize them. Figure 2(left) shows the faqade of the LESO-SEB. Each office room is equipped with two grey fabric blinds which can be controlled via four control switches inside the office (one “up” and one “down” switch for each blind). The upper blinds cover the actual ADS and are regularly used to reduce the illuminance levels when the users feel that there is too much daylight in the office or that the office seems too bright, and they are also used for glare protection (i. e. to block out direct sunlight). The lower blinds are used less frequently by most users and serve mainly for glare protection. However, the interviews carried out during this study have revealed one important weak spot of this blind configuration: For technical reasons, small gaps occur

|

between the blinds of the different offices (see Figures 2(left) and 2(right a)) ). At some moments of the day, these gaps can lead to glare problems in an office even though its respective blinds are lowered. These glare problems get even worse when the blinds of a neighbouring office are left open (e. g. due to occupant absence in this office). Figure 2(right b)) visualizes one potential way to deal with these problems: Instead of installing all blinds at the same distance from the facade (as illustrated in Figure 2(right a)) ), every second blind could be shifted away a small distance from the facade. Like this, the gaps could be closed. On the other hand, such a modification might lead to shading of offices by their neighbouring offices’ blinds and therefore to conflicts between the building occupants.

Figure 2: Left: The LESO-SEB’s anidolic facade with upper blinds, lower blinds and gaps between the blinds. Right: Schematic view of existing and optimized blind configuration.

|

Another possibility to deal with the above mentioned problems related to gaps between the different external blinds would be to improve an internal, manual curtain system made out of numerous long fabric curtain elements (see Figure 3( left) ) already installed within the offices. The occupants can manually open and close these curtains and also tilt the curtain elements around their vertical axes. However, these curtains do not seem to be frequently used and were described as “quite annoying” by some interviewed occupants. It might be indicated to think about installing a more adapted blind system here. Another weak spot pointed out by some occupants are the small lateral windows that exist between some of the different LESO-SEB offices (see Figure 3(right)). These lateral windows can sometimes cause glare to the occupants when the external blinds of their neighbouring office are open. The resulting annoyances could easily be avoided by installing an additional small blind at this point of each office.

The computational code was validated by reducing it to cases reported in the literature [7], obtaining a very good agreement. The maximum percentage temperature difference of 2 % was obtained considering an irradiance of 400 W/m2, an absorbing plate of 2.0 m high and of 0.145 m channel width.

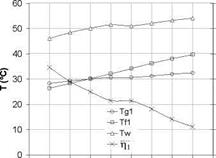

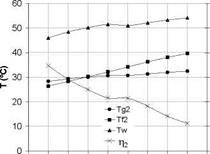

Parameters of Tables 1 are input to simulate the performance of the solar chimney. A length Lt=2.0 m, a width Wi =1.0, a depth di = 0.15 m, an irradiance Gi =200 W/m2 , and the ambient temperature Ta i=25 °C (298 K) were used. Curves of Glazing temperatures, metallic plate temperature and thermal efficiency are plotted as a function of the length of the solar chimney for both channels in Figure 3. It is observed that, all the temperatures increase as the length of the vertical plate increases, however, the efficiency decreases as length of the vertical plate increases. Because the optical properties of Table 1, symmetrical results were expected for both channels, (Figure 3, a-b).

|

|

|

|

|

Fig. 3. Temperature and efficiency vs. length for both channels of the solar chimney. Irradiance of 200

W/m2, ambient temperature of 25°C (298 K), channel depth of 0.15 m, channel width of 1.0 m, area rate of

A0/Ai=1.0, discharge coefficient of Cd=0.52, and wind velocity of 3.0 m/s.

Also, the figure shows that for 1.0 m length, a small step appears in the temperature curve of the metallic vertical plates Tw, as well as in the efficiency n curve. These fact is attributed to the change of Nusselt number correlation, from laminar to turbulent flow (Equations 6, 7), as was reported by Ong, 2003. The maximum temperatures were obtained at L=2.0 m, Tw=54 °C, Tf=40 °C, and Tg=32 °C. The efficiency n was from 35 % at L=0.25 m to 11 % at L=2.0 m.

The average thermal efficiency and mass flow rate leaving the solar chimney as a function of the incident solar radiation is presented in Figure 4. The same previous input parameters of Table 1 and 2 were used except for G=60-500 W/m2. As we can see, the thermal efficiency increases from 11 % to 28 %, and the mass flow rate increases from0.01 kg/s to 0.03 kg/s.

|

0 100 200 300 400 500 600 700 Irradiance (W/m2) Fig. 4. Efficiency and mass flow rate vs irradiance for one channel of the solar chimney. Irradiance of 60-500 W/m2, ambient temperature of 25°C, channel depth of 0.15 m, channel with of W=1.0 m, area rate of A0/A1=1.0, discharge coefficient of Cd=0.52, and wind velocity of 3.0 m/s. |

2. Conclusions

Natural ventilation systems like solar chimneys have become important devices lately. Its theoretical study has been intensified since the last three decades, which has helped to understand its performance. The performance of a two flow solar chimney was theoretical studied, the results showed that, temperature of the metallic plate Tw, the fluid temperature Tf, and the glass temperature Tg, increase, and the efficiency decreases as the plate length increases. The average maximum flow rate through the two flow chimney was 0.06 kg/s, when incident solar radiation was 500 W/m2. A very low efficiency (r <30 %) was obtained when natural convection is used for this device.

Further theoretical and experimental study is in progress to predict more accurately its thermal performance.

The authors acknowledge CONACYT, DGEST-SEP, AECI, and DGET-UNAM, for their support to this project.

A, Inlet area, (m2).

A0i, Outlet area, (m2).

A і Area aspect ratio.

Cd, Discharge coefficient of 0.52. c/; Air specific heat, (kJ/kg. K) d. Channel depth, (0.15 m). g Gravitational constant, (9.81 m/s2).

G Irradiance, (W/m2).

Gr Grashof number.

g ,w, i

hgConvection heat transfer coefficient for glass cover, (W/m2.K).

hw. Convection heat transfer coefficient for the metallic plate at both sides, (W/m2.K).

h Wind heat transfer coefficient, (W/m2.K).

hng., Radiation heat transfer coefficient, from the metallic plate to the glass covers, (W/m2.K). hrsi Radiation heat transfer coefficient from the glass cover to the sky, (W/m2.K).

(і = 1, channel one, and і = 2, channel two. kf, is the thermal conductivity of air, (W/m. K),

Lc is a short length of the chimney, Lc = Lt /10, (m),

L is the total length of the chimney, (m),

M, Theoretical parameter.

ml Mass flow rate through each channel, (kg/s).

Nui Nusselt number.

Ra t Rayleigh number.

sg. Solar irradiance covering the glazing at both sides, (W/m2),

SwJ, Transmitted solar irradiance covering the metallic plate, at both sides, (W/m2). T Ambient temperature, K.

Ta. Air temperature at the inlet, (K).

Tmi Mean temperature, (K).

T = Tai, Room temperature, (K).

Ts Sky temperature, (K).

Ut. Top loss coefficient, (W/m2.K).

V, Wind velocity, (m/s).

W is the width of the channel, (1.0 m),

Greeks ag. Glass absortivity.

awi Metallic plate absortivity.

PfJ Volumetric coefficient of expansion, (1/K).

у Experimental constant (0.75), Hirunlabh, [12].

Gg, i Glass emissivity.

£wi Metallic plate emissivity.

Dynamic viscosity of the fluid, (kg/s. m).

vfi Kinematic viscosity, (m2/s).

pot Air density, (kg/m3).

c Stefan-Boltzmann constant, c = 5.67x10s W/(m2K4)

Tgit Glass transmissivity.

^ Efficiency, (%).

References

[1] Mathur J., Bansal N., Mathur S., Jain M., Anupma “Experimental investigation on solar chimney for room ventilation”, Solar Energy, Vol. 80, pags. 927-935, 2006.

[2] Bouchair A., “Solar chimney for promoting cooling ventilation in southern Algeria”, Building Serv. Eng. Res. Technol. 15 (2): 81-93, 1994.

[3] Gan G. “A parametric study of Trombe walls for passive cooling of buildings” Energy and Buildings, 27: 37-43, 1998.

[4] Gan G. y Riffat S.,“A numerical study of solar chimney for natural ventilation of buildings with heat recovery”, Applied Thermal Engineering, Vol. 18, Pags. 1171-1187, 1998.

[5] Marti H., Jaime “Analisis de la chimenea solar del LECE para su caracterizacion energetica como sistema de ventilation natural en la edification”, Proyecto Energia Solar en la Edification. Departamento de Energias Renovables. Ciemat. Avd. Complutense 22, Madrid 28040. Septiembre de 2003.

[6] Marti H., J. y M. R., Heras C. “Dynamic physical model for a solar chimney”, Energetic Efficiency in Building. Renewable Energy Department. Ciemat. Avd. Complutense 22, Madrid 28040, Solar Energy, 2006.

[7] Ong K., “A mathematical model of a solar chimney”, Renewable Energy, Vol. 28, Pags. 10471060,2003.

[8] Duffie J. A., Beckman W. A., “Solar Engineering of Thermal Processes”, 2nd Ed. John Willey & Sons, Inc. 1991.

[9] Modest M. F., “Radiative Heat Transfer”, McGraw-Hill, Inc., 1993.

[10] Incropera F. P., De WITT D. P., “Fundamentals of Heat and Mass Transfer”, 5th Ed., John Willey & Sons, 2002.

[11] .Bansal N., Mathur R., y Bhandari M., “Solar chimney for enhanced stack ventilation”, Building and Environment. Vol. 28, Pags. 373-377,1993.

[12] .Hirunlabh J., Kongduang W., Namprakai P., y Khedari J., “Study of natural ventilation of houses by a metallic solar wall under tropical climate”, Renewable Energy, Vol. 18, Pags. 109119, 1999.

The guideline document finalised in the framework of the programme, as already stated, defines the basic general requirements to be fulfilled by the solar DHW projects. Based on that, the technicians responsible for the compilation of the call for tenders can define the specific obligations for a given project and, then, simply adapt the “Standard Technical Specifications” document to the jail needs.

The basic principles behind the technical specifications adopted for the completion of the programme (Table 1) are the followings:

1. The quality of the products, of the plant design and installation and the qualification of the installers are considered crucial for successful projects.

2. Multiple design choices are allowed whenever they fulfil the quality issues.

3. The annual energy to be supplied by the solar thermal plant is the main requirement. The plant size is implicitly defined by the expected output and may vary for different collector types and/or system configurations.

4. A Guaranteed Solar Results contract jointly with an appropriate maintenance procedure are expected to ensure the reliability of the system in operation.

5. Monitoring is considered crucial in order to detect possible areas of improvement.

6. Precautions against the proliferation of the legionella bacteria are especially addressed.

Last, but not least, possibilities for energy savings on the demand side could be preliminary detected and integrated into the solar thermal plant design.

Due to similar operating conditions, the design and installation criteria identified for a solar DHW plant in a jail can be easily extended to other public large DHW consumers.

|

Table 1. Examples of the specifications for the implementation of a solar DHW plant in a j ail in the framework of the Solar Jails Program.

|

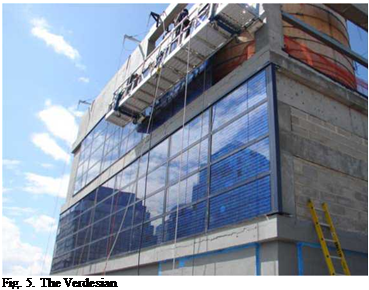

The Verdesian is a USGBC LEED Platinum Green Building and benefited from all the past knowledge gained by altPOWER and the same development and construction team as the Solaire.

|

The design is a true custom glass/tedlar laminate BIPV facade system for the east, south and west walls of the mechanical bulkhead at the top of the building. A pre-glazed cassette wall system was used, with multiple module sizes. This system was installed by Ornamental Ironworkers and wired up by Electricians later. The installation was the quickest at the time of completion and went smooth in every way, also receiving a Field Listing from UL after installation.

4.2.1 Heating supply ability in winter

|

|

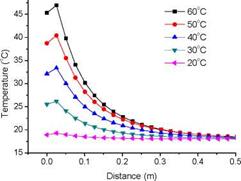

It is clearly known that the supply temperature significantly influence the energy supply amount of the end systems. This work was done on the energy supply system in the present paper.

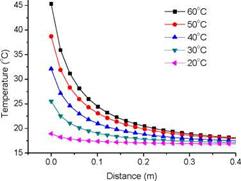

Fig.7 The floor temperature distribution Fig.8 The wall temperature distribution

of different medium temperature of different medium temperature

The water supply temperature are set as 20°C, 30°C, 40°C, 50°C and 60°C, with the ambient

temperature of 0°C and the indoor air temperature of 18°C. Fig.7 and Fig.8 represent the floor temperature distribution contrast curve of different medium temperature and the wall temperature distribution under different medium temperature, respectively. It can be seen from Fig. 7 and Fig.8 that the floor temperature and wall temperature increased with the increasing of the water supply temperature and temperature distribution in different water supply temperature showed a similar trend. A temperature peak value appearing on the floor surface where is approximately 0.02m form wall corner, this can be ascribed to the location of the embedded pipe; the wall temperature distribution is a monotonically decreasing function of the height of the wall, the reason is that, no any embedded pipe in the wall.

|

Water supply temperature (°C) |

20 |

30 |

40 |

50 |

60 |

|

Thermal flux of the floor surface (W/m2) |

7.3 |

40.4 |

74.1 |

108.6 |

141.3 |

|

Thermal flux of the wall surface (W/m2) |

9.3 |

29.5 |

52.6 |

75.8 |

99.1 |

|

Total thermal flux (W) |

77.0 |

321.3 |

581.5 |

846.0 |

1103.1 |

|

Increment of the total thermal flux (W/10K) |

— |

244.3 |

260.2 |

264.5 |

257.1 |

The computed results of ability of supplying heat with different water supply temperature are listed in Table 5. It can be seen from Table 5 that temperature increasing of the water supply can greatly increase heat supplying ability. There was a linear relationship between the increment of the total thermal flux and the increment of the water supply temperature.

The basic principles of the design encompass a sensitive approach to the site, interaction with the existing religious activities and an architecture that uses simple and yet grand means to evoke the desired religious effect. Two basic elements, a 125m diameter circle and a linear element in the form of two large span (80m) beams intersecting it, are the geometric shapes that dominate the architecture.

A symmetrical layout has been chosen for symbolic, aesthetic and functional reasons due to the size of the building, so as to enhance monumentality and the closeness of the congregation to the Presbytery.

The building is developed on two levels. The main ground level gently rises from the existing square.

|

Fig.3 Night view |

The Chapels in front are developed underground so as not to exceed the floor level of the square and impede the monumental relationship of the main structure and the square. Other auxiliary spaces are also entirely developed underground with connecting ramps and stairs to the main areas of circulation.

The Church has a recessed main entrance on the level of the square. Access ramps, defined by the two side walls and the two centrally located shallow reflecting pools contribute to a gradual transition from the open, inevitably noisy public space of the square, to the underground Chapels and confession areas, preparing the visitors for contemplation and prayer.

2. Function

Functionally, the main interior space, which further to its function as a Church can also be used for assemblies, can be divided into two zones. Accordingly, the hall can be used either for a smaller number of up to 3,000 or to its full capacity of 9,000 persons.

|

|

Water and electricity bills covering a three-year period were analysed and found to average 0.8 m3 and 37 kWh per day respectively. These rates appeared particularly high when compared to the national average. Moreover, the electricity consumption in winter was higher than that in summer, which was in contrast with the local trend of the domestic sector that used more electricity in summer for space cooling. During the three-month duration of this investigation, electricity consumption was found to be highest for the electrical heater of the solar tank and this explained the peculiar increase in electricity consumption in winter. Table 2 shows the energy consumption for different appliance categories, as a percentage of the total daily demand.

Table 2. Electricity consumption by appliance category.

Appliance Category Electricity Consumption Percentage Share

IT Equipment (Internet, Printers, Laptop, etc.) 3.4%

Kitchen (Cooking, Fridge/Fridge-freezers, etc.) 25.6%

Artificial Lighting 20.7%

Laundry (Washing, Drying, Ironing, etc.) 3.5%

Audio / Visual Equipment (TV, DVD, etc.) 7.5%

Solar Water Heating Back-up Electrical Element 39.3%

The kitchen was the second highest area of electricity use due to the fact that no gas was utilised for cooking purposes. Artificial Lighting followed with a share of almost 21%, since most of the bulbs used were incandescents.

Approximately 5 kWh per day were consumed in stand-by mode, with 41% being attributed to Information Technology (IT) equipment (laptops, modems, printer, etc.) and the remaining 59% being consumed by audio-visual entertainment equipment (television sets, DVD players, etc.). It was noted that many appliances, which were in stand-by mode in the penthouse, were rarely being used.

While it is generally believed that solar water heaters (SWH), which replace traditional electrical boilers, could contribute towards a reduction in electricity consumption, a different picture unfolded during this auditing exercise. The back-up electrical heater was consuming 14.5 kWh per day, which led us to concentrate our investigations on the solar heater, as shown below.

It turns out that in Polish climatic conditions it could be the special problem with overheating of rooms located at west side of a building. In summer west vertical surfaces (see Fig.6) receive much more solar radiation than south vertical surfaces. Taking that into account and analyzing distribution of solar irradiance on surfaces with different inclination and orientation throughout the whole averaged year the decision was made according to the final shape of the building (see Fig.1 and Fig.7 -8) [3]. The main facade has partly flatted cylindrical shape and is directed from the south — east to the south — west direction. The back side of the main building (see Fig. 7) is directed to the north (from north — east to the north — west). The EDI building consists of segments with different orientation. For the main facade, starting from the east to the west, it is as following: — 420, — 310, — 190, — 80 (main hall in the centre of the EDI building), +30, +140, +260, +370 (small

|

segment between EDI building and the swimming pool), +420 (the swimming pool). The roof of the EDI building is inclined at angle equal to 30o (see Fig.8) and consists of the similar segments as the vertical part of the building.

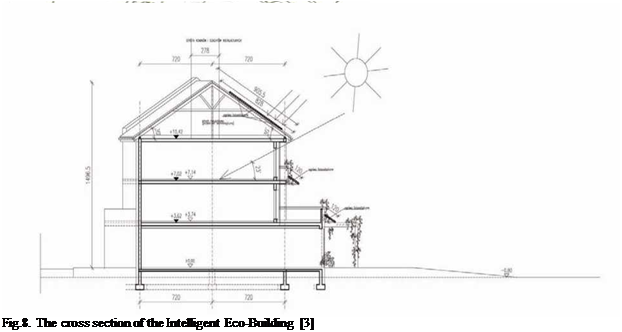

The architectural concept of the 3 storey IEB building has been developed with regard to active and passive application of solar energy. The shape of the building assures maximum gains of solar energy per year for active and passive systems. Shading elements are also included. Apart from traditional devices as blinds and building envelope elements as overhangs, the PV modules are to be applied and natural green environment (building is to be surrounded by pergolas at the front glazing facade). PV modules are to be located on the roof with slope of 300 and constitute shading elements over balconies of hotel rooms and over the main entrance — reception hall (glazed roof) in the middle of the building.

All “south” rooms at the first floor are seminar and lecture rooms. The main open space is the central hall, that can be used as a conference hall, banquet hall and exhibition area. Hotel rooms are at the second and third floor, mainly at the “south” side. The “north” side is designed as not living room space. It will include technical rooms, stores, measurement — monitoring rooms and some office rooms.

Heat will be supplied to the building by ground heat pumps, solar collectors and auxiliary biomass boiler located at the boiler room at the east side of the building (the plantation of energetic willow will be located nearby.

The IEB building is connected at the west side with the swimming pool and fitness center. Shape of a roof of the swimming pool is shown in Fig. 1 and Fig.7. The slope of the roof is 350, and the orientation is +300. The roof has been especially designed in such form to improve solar energy utilization. Solar collectors will be located at the roof and will supply heat to the swimming pool and the IEB building. Laboratory buildings are connected with the IEB building via bypasses shaded by PV panels on passes roofs. Location of all buildings and active solar systems has been analyzed taking into account the shading of the surrounding elements: natural (trees) and artificial (building in the vicinity). At present, technical concept of the Center is under development.

References

[1] D. Chwieduk, Some Aspects of Modeling the Impact of Solar Energy on the Energy Balance of a Room, Solar Energy (in print).

[2] D. Chwieduk, B. Bogdanska, Some recommendations for inclinations and orientations of building elements under solar radiation in Polish conditions, Renewable Energy Journal, 29 (2004) 1569 — 1581.

[3] D. Chwieduk, E. Kossecka, P. Murza — Mucha, Opracowanie kompleksowej koncepcji Centrum i szczegolowych zalozen do jego budowy, Raport projektu Konwersja Energii i Zrodla Odnawialne — Centrum Badawcze w Jablonnej. Zadanie II.1.

[4] D. T. Reindl, J. A. Duffie, W. A. Beckman, Evaluation of Hourly Tilted Surface Radiation Models, Solar Energy, 45 (1999) 9 -14.