Как выбрать гостиницу для кошек

14 декабря, 2021

Within a research project that started in 2005, four case studies for medium sized companies located around Kassel (Germany) were carried out to analyse the suitability of implementing solar heating systems for process heat generation. Specific and overall heat consumption and temperature ranges were estimated or measured and transient needs of the heat supply systems were analysed, with focus on existing stores and hydraulics, used fluids (e. g. steam cycles) and possibilities for heat recovery installations [7]. The Hutt brewery in Kassel is one of the investigated companies. It was founded in the 1750’s and has a current staff of about 60 employees today. The brewery produces approximately 80,000 hl of beer per year and has an annual final energy consumption of 6.5 GWh. More than 80% of the energy is supplied by natural gas and used to provide process heat, hot water and space heating. All heat consumers are connected to a steam network that is fed by a boiler (P = 2.6 MW*). The production process is operated in one shift on five days per week. During summer, the amount of produced beer increases by a factor of 1.3 compared to the winter period. Based on their production capacity, technical installations and energy consumption, the Hutt brewery is a representative example for a typical SME in the brewing sector. The continuous development over the last decades with structural alterations and technological changes led to a non-optimised combination of production sites, installations and energy supply. Thus, energy efficiency measures of different complexity can be realised within several sections of the production process.

|

|

|

Steam Steam Steam Fig. 1. Schematic of the brewing process at the Hutt brewery. The respective temperatures are similar to other breweries. |

Independent from the specific characteristic of a brewery, the production of beer can be divided into three parts: brewing, fermentation/storage and filling of bottles, kegs or cans. Figure 1 shows the simplified scheme of the production process at the Hutt brewery. In the beginning, the wort is produced within the brewhouse by mashing, lautering and boiling. After cooling the wort, it is stored in the fermenting cellar. Once fermented, the beer is filled into bottles and kegs. Within the production process, the brewhouse has a share of 40..50% of the overall heat consumption. The bottle and keg filling hall, with the bottle washing machine as biggest consumer, requires about 20..30% of total heat demand [8]. Besides a small amount of hot water for filtration, there is no significant heat demand within the process step fermentation and storage. However, this part is characterised by high electricity demand for cooling.

To dry wood the surrounding air must be sufficiently dry so as to absorb its moisture. This can be accomplished either by ventilating or heating the kiln air. During the first stage of the drying cycle, air easily absorbs the moisture and relative humidity inside the chamber may keep close to 100%, with water often beading on the walls in a based-greenhouse structure. As the process evolves wood moisture expelling turns increasingly difficult, mainly due to the low diffusion speed of moisture in wood. At a final stage, when all free water has been lost, only cell bonded moisture is left to be extracted. This final stage is more time and energy consuming, since it requires additional energy supply to break the bonds. Quality regards are present in the intermediate and final drying stages. In this process temperature, relative humidity and wood moisture content are the most relevant quantities [2-3Conventional drying

The main purpose of lumber air drying is to evaporate as much water as possible before end use or transfer to a kiln drier. Air drying can usually proceed until wood moisture content attains 25% to 20%. Another drying methodology must follow if a lower target value is desired. Air drying saves energy costs and reduces required dry kiln capacity, but presents the usual limitations of an uncontrolled process: in winter months drying rates cold be very slow, particularly in raining periods. By other hand under summer hot dry winds wood quality may be degraded as a result of surface shrinking and end splitting, due to severe differential drying (surface vs. interior). Another drawback of this method is the space and long time storage costs of wood stacks, implying large immobilization periods [4]

In kiln drying processes, higher temperatures and faster air circulation are used to considerably increase drying rate. Specific drying schedules/profiles have been developed to control temperature and relative humidity in accordance with the moisture content and stress situation within the wood, in order to minimize shrinkage-caused defects and improving quality. Conventional drying is one of the most expensive processes in wood industry, due to the enormous thermal energy expenditure

[3].

Modern computer based simulation models have been developed and adapted to analyze the performance of solar-hybrid gas turbines in commercial system size [4]. Software tools have been developed for combined heliostat field and receiver layout. Some very interesting results have been presented by modeling the power plant with TRNSYS using the STEC model library for annual performance simulation [5]. This model was able to estimate the annual electric output for various design parameters (solar field size, storage size, power block efficiency) and different simple operation strategies. For the whole system of a solar tower power plant consisting of a solar and a conventional part a new model is necessary to be developed for the description of each component of the power block.

The implementation of the solar tower power plant model has been done in the MATLAB/Simulink environment.

MATLAB is a high-performance language for technical computing. It integrates computation, visualization, and programming in an easy-to-use environment where problems and solutions are expressed in familiar mathematical notation.

Simulink is a toolbox in MATLAB that provides an environment for modelling, simulating, and analyzing dynamic systems. It supports linear and nonlinear systems, modelled in continuous time or a sampled time. The implementation of systems can also be multi-rate, i. e. have different parts that are sampled or updated at different rates [6].

3.1. General remarks

In general solar energy can be used the better the higher the temperature level is. Even if it can be used exceptionally at low temperatures, e. g. for swimming pool heating, for water heating resp. preheating, for preheating for room heating support or for increase of the back-flow temperature, these processes could be much more efficient at higher collector temperatures. This is to be explained in the following.

3.2. High collector temperatures increase the efficiency factor of the installation:

The conventional backup heating can only be avoided efficiently and permanently if the solar outlet temperature is permanent considerably higher than the relevant desired temperature. As the efficiency factors of boiler and installation are especially bad out of the heating season, every single switching of the boiler avoided by solar heat saves many times the amount of energy that the solar collector system feeds into the tank. If e. g. a boiler working with oil with an efficiency factor of 90 % and an internal water volume of 60 l has to heat this water from 20 °C to 70 °C before it can heat 150 l hot water in the tank by 5 K, only 16 % of the consumed fossil fuel is used for water heating. Has the solar collector system, however, heated the hot water tank sufficiently and the boiler does not need to start, it saves with every solar kilowatt-hour 6.25 kilowatt-hours of fossil energy.

In addition to its annual solar energy harvest the solar collector system helps to save an amount of energy by avoiding boiler and installation losses that can be as large or even larger than the pure solar energy harvest. Low temperature collectors can never have this synergetic effect, not even in summer, because they need delta-T-controllers which usually prevent high temperatures.

Permanently high collector temperatures are coupled with big temperature differences what decreases the volume flow demand. Thus electrical pump energy and pump working time is saved.

In the development of flat-plate collectors and vacuum tube collectors for domestic hot water and for room heating applications it was sufficient to carry out collector efficiency measurements up to collector inlet temperatures of about 100°C. But the situation is different for the development of collectors which will have their main operating temperature in the range of 80 to 250°C. It is essential to carry out efficiency measurements directly at these high temperatures and not to rely on extrapolations from measured efficiency points at lower temperatures.

|

Therefore, at Fraunhofer ISE a new test facility was developed with which we can determine collector efficiencies at measuring temperatures up to 200 °C. It can be used in indoor measurements (with our solar simulator, see figure 6) and outdoor (with the tracker) [7].

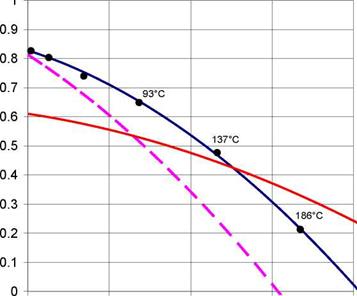

Figure 7 shows examples of measured efficiency curves of three different collectors. All curves were measured in the solar simulator laboratory (indoor measurements) and with the new testing facility.

The measurement points at the highest temperatures were taken at mean fluid temperatures of about 185° — 190°C for all three collectors. The actually measured efficiency points are indicated in the diagram for the evacuated tubular collector 1. It is a collector without a CPC reflector and with relatively narrow gaps between the single evacuated tubes. These measurements were taken at an irradiation of 931.9 W/m2. Therefore also the two other curves are given for this irradiation which is necessary in order to plot all three curves in one diagram. In all measurements the ambient temperature was in the range of about 30°C. The second evacuated tubular collector uses a CPC reflector. The heat losses based on the aperture area are therefore smaller and the efficiency curve is higher than for collector number 1 at higher operating temperatures. The efficiency curves show that both evacuated tubular collectors are suitable for system applications in which the collector operating temperature is in the range above 100°C and may be up to 150°C. The flat-plate collector has a highly selective absorber coating and is glazed with a single, anti-reflectively coated glass.

![]()

![]()

re

re

£

3

t

Q.

re

£

(Tfiuid-Tambient)/G in (K m2)/W

Figure 7: Measured efficiency curves of three different collectors (indoor measurements with solar simulator, highest mean collector temperatures about 185° — 190°C for all three collectors. The dots show the actually measured efficiency points for collector 1 and the mean collector fluid temperature in the measurement.

For a summary on the achievements of the work of IEA-SHC Task 33 SHIP considering the development of process heat collectors I want to make the following statements:

• A good start has been made. Different new collectors for the operating temperature range of 80 to 250°C are under development. The Task had a positive triggering and integrating impact with a high degree of information exchange.

• With regard to realized demonstration plants and built application systems, it has to be stated that almost all of them are working at temperatures below 100°C. Of course, there is also a big potential for solar heat in industrial processes below 100°C, but the full potential for heat up to about 250°C can only be used if new and appropriate collectors are developed. As mentioned, a good start is made, but a lot of development work and research activity is still needed.

• New requirements have to be fulfilled with respect to collector components, materials and system components of the solar loop:

— appropriate heat transfer fluids sufficiently temperature stable, anti-freeze properties, efficient thermodynamic and hydraulic performance

— cost effective reflectors with high performance and long service time

— tracking systems which are reliably operating for the whole service time

— appropriate receivers (with and without selective coating, applicable in vacuum of in atmospheric conditions)

— appropriate and temperature stable pumps, piping and connection systems, heat exchangers and valves and other system components.

• New collector testing standards and testing facilities are required, especially for CPC and concentrating collectors. The aim must be to achieve a full technical and economical comparison for the full range of the collector technologies.

Acknowledgement

I want to thank all colleagues who contributed to Subtask C and to the booklet Process Heat

Collectors. The work contributed by Fraunhofer ISE has been carried out with financial support by the

German Ministry for the Environment, Nature Conservation and Nuclear Safety.

[1] Werner Weiss, Irene Bergmann, Gerhard Faninger, (2008), Solar Heat Worldwide — Markets and Contribution to the Energy Supply 2006, Edition 2008, http://www. iea-shc. org/publications/statistics/IEA- SHC_Solar_Heat_Worldwide-2008.pdf

[2] Werner Weiss (2008), Solare Prozesswarme — Potenziale, Einsatzbereiche und Herausforderungen fur die Solarindustrie, 18. Symposium Thermische Solarenergie, Bad Staffelstein 23.-25. April 2008, pp159-164.

[3] Henning, Hans-Martin (Ed.) (2004), Solar-assisted air-conditioning in buildings — A handbook for planners, Springer Verlag Wien New York, ISBN 3-211-00647-8

[4] M. Wieghaus, J. Koschikowski, M. Rommel, (2008) Solar desalination for an autonomous water supply, Desalination and Water Reuse; for more information visit www. solarspring. de

[5] Chr. Thoma, Th. Weick, J. Richter, Th. Siems, M. Rommel (2008) Testing fo solar air collectors, Proceedings of Eurosun 2008, Lisbon

[6] Werner Weiss and Matthias Rommel (Ed.), (2008) Process Heat Collectors, downloadable from http://www. iea-shc. org/publications/downloads/task33-Process_Heat_Collectors. pdf.

[7] M. Rommel, K. Kramer, S. Mehnert, A. Schafer, T. Siems, C. Thoma, W. Striewe, (2007) Testing Unit for the Development of Process Heat Collectors up to 250°C, estec 2007, Proceedings of the 3rd European Solar Thermal Energy Conference, June 19-20, 2007, Freiburg, Germany, pp 414-418

Simulations were carried out for concrete slabs of 20, 40 and 60 cm thickness. However, the piping of the underfloor heating system was always installed at a depth of 10 cm. The floor thickness shows only a small sensitivity with respect to the solar fraction that can be reached with the system. Doubling or even tripling the floor thickness leads to an increase in solar fraction of only a few percentage points. Therefore, a floor thickness around 30-50 cm is a reasonable value. Floor slabs in this order of magnitude are commonly used in many industrial buildings anyway.

When the results are plotted against the utilization ratio, as it was done for the system concept with storage tank, the points scatter significantly more (see Figure 6). The highest solar fractions are obtained with the standard reference case. In Case 4 (8 kW internal gains), solar fractions are lower because during the day the machine operation leads to high air temperatures and high floor temperatures, therefore the solar thermal system cannot store much heat in the concrete mass. In this case, using the thermal mass as a storage tank is particular unfavorable because the solar energy cannot be stored to be used during the night. In Case 2 (poorly insulated), solar fractions are again lower. In this case, the overall heat demand of the building is much higher and as a result the conventional heating system is turned on more often. The conventional heating system also uses the underfloor heating system, which leads to higher average floor temperatures. If this is the case, then the potential for solar heat to be stored in the floor is decreased, which in turn decreases the solar fraction that can be reached. This effect is even more pronounced in Case 1 (poorly insulated and high air exchange rate). In this case, the overall heat demand of the building is so high that the

|

conventional heating system has to be turned on almost all the time. Therefore, solar fractions are decreased dramatically.

Regarding the nomogram for systems using the concrete slab as heat store, it is even more important to remember that the results shown can only give a rough approximation of the solar fractions that can be reached. The results are only strictly valid for the reference buildings described above. Systems without water store are even more sensitive to a change of boundary conditions as could be shown with the different reference cases considered. If for example, a building is much higher than the reference buildings or a higher air temperature is required, this can have a strong influence on the function of the concrete slab as a heat store. It not only increases the heat demand of the building but also decreases the solar fraction that can be reached. Therefore, a more detailed simulation of the building and the heating system may be necessary if the thermal mass is to be used as the only heat store.

As for systems that use a water storage tank, systems should be designed in accordance with the optimum cost-to-benefit ratio (orange area, degrees of solar fraction of the overall heating requirement between 15 and 30%). Degrees of solar fraction of less than 15% are outside the cost- to-benefit optimum since the (slight) rise in the specific yield does not make up for the higher specific system costs of a smaller solar thermal system and would thus lead to higher solar heating costs.

Considering the preliminary assessment of a small scale shaft power generation system, yearly simulations where performed, for three different locations, after the following parameters:

• ORC operates at full load (i. e., whenever QinORC is available);

• heat produced in the solar field at ToutSolar = T2 + ATm (i. e. variable fluid flow in the solar field circuit);

• inlet temperature Т1пВЫаг calculated after constant outlet temperature condition and heat exchanger parameters (vide Table 1);

• heat stored in unstratified storage system at T2 + ЬТШ;

• heat delivery priority levels: 1. solar field; 2. storage system; 3. backup system;

• circuit and storage heat losses neglected.

Solar field inlet temperature calculation follows heat exchanger operation, a minimum temperature difference of 5 K and 10 K between heat transfer fluid and working fluid of the ORC was adopted for cycle 2 or cycle 3 respectively, according to regenerator outlet (T), evaporation (Tevap), and

superheating (T2) temperature values [17]. Average heat addition temperature (Ty-2) rounds 113.5 °C, for cycle 2, and 166.6 °C for cycle 3 conditions.

The use of thermal energy storage (TES) is considered regarding a daily increase of solar based operation. The size of the TES (QTES. max) is given in terms of storage time, traducing, for a general storage material, the amount of energy required to run the system for a given time period (AtTESmax), according to equation 1:

It is important to refer that such simplified system operation conditions are likely to penalize solar field results, considering that no heating regimes are considered in the non stratified storage system and that the solar field is forced to operate permanently under maximum temperature conditions.

Yearly system performance calculations where carried out for three different locations: Almeria (Spain), Cairo (Egypt) and Moura (Portugal) after hourly average data series for global horizontal and diffuse irradiation, as well as ambient temperature, whose average monthly values are presented in figures 2 a) and 2 b).

Regarding a dimensioning assessment of both solar field and storage system, system configurations with and without energy backup where simulated after the following dimensioning parameters:

• total collector area heat є [1500, 2000, 2500, 3000, 3500, 4000, 4500] (m2);

• storage capacity є [0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12] (h).

As can be seen from the huge amount of breweries, there is a big variety of beers and every beer has more or less its individual recipe. One can hardly find two identical brewing processes in two different breweries, which is also influenced by the personal preferences of the respective brewer. Besides variations in used raw materials such as grains, hops and yeast, there are differences in time periods and temperature ranges during the wort production. Additionally, there are various technical installations available for mashing, lautering and boiling as well as heating or cooling the wort. This leads to the fact that the detailed knowledge of the brewing process in Brewery “A” might not result in a similar knowledge of any other brewery “B”. Within the brewhouse, there is a great difference in existing mashing and boiling systems.

At the Hutt brewery, the brewing process starts with mashing by mixing crushed malt with 58°C hot water in the mash tun. Within the next two hours, the mash follows a defined time-temperature profile with various temperature rests. Therefore, the shell of the mash tun is heated by steam. The principle of mashing (heating a mixture of water and grains) is more or less the same in all breweries. The diversity is based on the starting temperature, heating rate, way of heating the mash, set temperature and time for mashing as well as the used number and types of the mash tuns.

In the next process step called ‘lautering’, the resulting liquid is separated from the grains. Besides straining the mixture, the resulting draff is washed with hot water (around 80°C), to extract additional sugars. The variety of lautering processes in terms of consumed thermal energy is relatively small compared to mashing or boiling. Main differences can be found by the used lauter tun units. The temperature and proportion of hot water for this process step are more or less in a similar range.

Afterwards, the wort boiling takes place, which is the most energy intensive process step within the brewhouse. Before the wort is boiled, it has to be pre-heated from lautering temperature (around 75°C) to boiling temperature. This can be done by different methods, such as using the boiling copper or an external heat exchanger that is fed by steam, by high pressurised hot water or by recovered heat. After pre-heating, the wort is boiled for a fixed period, while hops are added to the wort. The respective boiling time and temperature is directly linked to the desired amount of evaporated water and the installed boiling system. This leads to different boiling times for different beer recipes or breweries. Another variation during wort boiling is given by the installed heat recovery system. At the Hutt brewery, the occurring vapours are condensed to heat brewing water that is temporarily stored in a hot water tank. Based on the respective installation, the recovered heat can also be used for pre-heating of lauter wort or boiling itself. For pre-heating of lauter wort, the evaporated water is condensed and heats water in a closed heat recovery cycle to a preferably high temperature level. This water is used to heat the lauter wort with a special heat exchanger from 75°C close to boiling temperature. The second possibility, using the recovered heat for wort boiling, is realised by using a special vapour compressor (thermally or mechanically driven). The compressed vapour can be used to heat the wort during boiling with a special heat exchanger.

After boiling, the so called ‘hot trub’ (remaining solid particles) is separated from the wort within a whirlpool. The wort is pumped tangential into the whirlpool, which causes a sedimentation process. After leaving the whirlpool, the wort is cooled by a double-stage heat exchanger. At first, the wort is cooled to approximately 15°C while cold brewing water is heated to 80°C and fed to a hot water storage tank. In a second step, ice water is used to cool the wort to a temperature below 10°C. The separation within the whirlpool is rather similar in all breweries. Solely the temperature level of hot wort can vary, which is based on the respective boiling process. The heat recovery installations for wort cooling are also comparable within different breweries. Usually, the amount of produced wort is similar to the amount of brewing water, heated within wort cooling, and sufficient to cover the demand for mashing and lautering. After wort cooling, the wort production is finished and the wort leaves the brewhouse.

In solar kilns thermal energy comes from solar radiation and can be a reasonable and promising method for almost any wood industry to gain the capacity to dry wood at reduced costs [5-9]. Known past implementations rarely use control embedded in the drying process [11], resulting in poor quality and dry time improvements. However, current instrumentation capabilities allow cost effective control solutions.

In the SECMAD Project, wich means “energy efficient wood drying”, the whole concept of a kiln drier has been reviewed [10,12-14],, namely to reduce its cost and enhance solar energy collection (side walls, double ceiling, etc.). The concept uses natural and mechanical ventilation controlled by an instrumentation and control system, accounting for both internal kiln and external environment conditions.

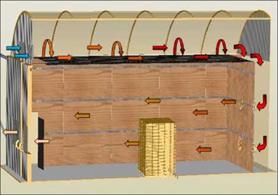

Figure 1 illustrates the driers prototypes and Figure 2 shows the ventilation and heating concept, with colors indicating the inside conditions of the air: red arrows give indication of direction of hot and dry air while blue ones indicate the direction of cold and humid air. Green arrows indicate the entrance of outside air, being heated by solar air collector at side wall and ceiling. Moisten air is expelled through vents by forced flow, while the fan is turned on. This solar and ventilation dryer is intended to be considerably faster than the traditional open air method and much lesser energy consumption and more cost expensive than conventional kilns.

Two prototypes were installed in two different industries. Prototype I is more appropriate for fresh water charged lumber, which is necessary to remove as fast as possible in order to avoid mould and blue stain when drying softwoods. Prototype II is more appropriate to dry products that need higher temperature and prove easier to remove the water without risk of checks and deformations (poles, agriculture fruits, etc.).

Dimensions of kilns are represented in both figures. Figure 1 prototypes could accept between 40 to 75m3 usable wood volume with equivalent dimensions: 4m inside height; 10 to 20m inside length; 5,60m inside width, but stacking of the wood, ventilation requirements and spaces from the rear wall and from front door gives a actual less wood processing.

![]() (Prototype II)

(Prototype II)

The model of temperature distribution and air circulation is shown in figure 2. The air speed on the ventilators was 13,5 m/s witch provides a volumetric speed of 160m3/min, or in other words, an average of 50 renovations h-1. The average air speed on the wood boards surface was 1,7 m/s on the stacks near the ventilators and 0,7 m/s on the surfaces of stacks more far way.

|

Fig. 2 — Heat model concept of lumber kiln dryer (cut sights).

|

The model library for the components of the steam cycle is shown in Fig. 2. This library consists of components for the steam turbine, pump, condensator, boiler, generator etc (Fig. 2). Also a library has been created for the hybridization components: a gas turbine and a burner as well as for the solar circle consisting of a heliostat field, a storage device and a receiver (Fig. 2).

Each component consists of input, output and parameter variables. For instance variables that are delivered from one component to the next are pressure, temperature, mass flow, enthalpy of the fluid. In addition, for certain components power or heat is a value that is used for calculation. The models are based on thermodynamic theory using assumptions to simplify the calculations. The assumptions are made in a way that the physical behaviour and a reasonable accuracy are maintained. The main reason for the simplification is to achieve a fast simulation for one year.

Steam Cycle

The main steam cycle components are the HRSG, the feed water pump, the steam turbine and the condenser. The HRSG consists of three stages the economiser, the evaporator and the superheater. Beneath the calculation of the generated saturated steam, the evaporator transmits the feed water demand to the pump by a signal. The last component of the boiler provides superheated steam for the turbine. The heat transfer is calculated with the input conditions of the hot air or exhaust gas by using the method of effectiveness of heat transfer. The turbine and the pump model using an inner efficiency to evaluate the output enthalpy and the power that is produced or consumed. Efficiencies can be set to a constant value or provided by a characteristic diagram. After the steam is expanded by the turbine it is condensed in the condenser. It is assumed that the water leaving the condenser is saturated. The conversation of energy and a constant temperature difference between the steam and the cooling water delivers the temperature rise of the cooling water.