Как выбрать гостиницу для кошек

14 декабря, 2021

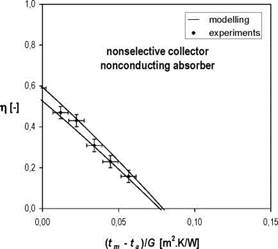

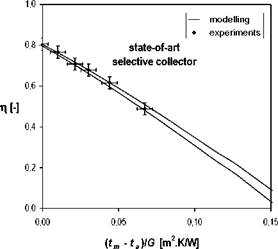

Mathematical model has been experimentally validated in the frame of solar collectors testing according to European standard [5] in the Solar Laboratory operated under Department of Environmental Engineering at Faculty of Mechanical Engineering, Czech Technical University in Prague. Different construction of tested solar collectors has been chosen to validate the results from mathematical model with instantaneous efficiency data obtained experimentally under steady — state conditions. Experimental data and efficiency curves calculated from model are graphically compared.

Experimental data points of solar collector efficiency are coupled with uniform uncertainty bars in the graphs. Expanded efficiency uncertainty has been assessed for experimental data from both type A (statistical) and B (instrumental) uncertainties considering the coverage factor 2 with 95% level of confidence [5, 6] and for usual steady state conditions of measurements is between 3 and 4 %.

|

|

The theoretical calculation of efficiency curve by model is subjected to uncertainty of input parameters. While geometrical parameters are easily available with high degree of confidence, number of parameters defining the properties of collector parts is found uncertain within narrow range (e. g. absorber and glazing properties parameters, mostly ± 1 %), middle range (e. g. conductivity of insulation layer dependent on its temperature and density, ± 10 %) and quite broad range (e. g. emissivity of absorber back side, insulation or collector frame, > 50 %). Each of varying parameter has a different impact (sensitivity) to resulting efficiency value from high effect of absorber and glazing optical properties to negligible effect of frame external surface emissivity. Uncertainty of input parameters and its influence to calculated efficiency has been expressed by two borderlines where the collector efficiency values can be found in reality.

Fig. 4. Experimental evaluation of the mathematical model by collector testing (different absorber quality)

Fig. 4 shows validation of the model for two examples of different atmospheric flat-plate collectors. Collector on the left consists of nonselective absorber without conductive bond to register pipes (steel absorber is bond to copper pipe only by spot grip-contact). Standard safety glazing and mineral wool insulation are used in its construction. Determination of absorber-pipes bond conductance is a main source of uncertainty in the calculation.

Collector on the right is a representative of high-quality solar collectors with state-of-art copper laser welded absorber. High performance selective coating and solar antireflective glazing properties from optical testing reports were provided thus reducing the uncertainty of calculation to very low values. Due to sufficient back side insulation the influence of uncertain internal and external surfaces emissivity has decreased to minimum.

![image007 Подпись: (tm - ta )IG [m2.K/W]](/img/1155/image007_0.gif) |

![image008 Подпись: (tm - ta)IG [m2.KIW]](/img/1155/image008_0.gif) |

Mathematical model has been also tested in the field of solar flat-plate evacuated collectors. Validation has been performed on commercial evacuated collector with selective absorber and no insulation applied at the back of absorber (only air layers at given pressure). The collector envelope consists of moulded metal frame and low iron glazing. Support pillars to bear the underpressure stress are placed between glazing and back side of the collector and penetrating the absorber through holes (elimination of thermal bridges, not considered in modelling). The atmospheric variant of the collector (interior pressure 100 kPa) has been evaluated as a reference case (see Fig. 5, graph on the left). The evacuated variant has been tested with interior pressure reduced to 9 kPa (see Fig. 5, graph on the right.

Fig. 5. Experimental evaluation of the mathematical model by collector testing (different interior pressure) 6. Conclusion and outlook

The principles of mathematical model and design tool KOLEKTOR 2.2 for design and virtual prototyping of solar flat-plate collectors have been described. Design tool allows the determination of solar collector efficiency curve, parametric analysis to obtain information on different parameters influence on collector performance and especially for investigation of thermal performance of advanced solar collectors (building integrated, evacuated collectors, etc.). The model has been validated by experimental data from testing of solar collectors with different construction concepts (atmospheric collector with spectrally non-selective and selective absorber; evacuated collector with selective absorber under different interior pressures).

The model and design tool is under continuous development. Validation of the model for unglazed solar thermal collector type is planned and huge experimental investigations are expected due to high uncertainty in modelling of wind convection heat transfer coefficients known from literature. Mathematical model of solar thermal flat-plate collector (glazed, unglazed) and design tool KOLEKTOR will stand as a basis for development of universal solar photovoltaic-thermal liquid collector model. Advanced PV/T model will allow PV collector modelling (fluid mass flow equal zero, considering influence of temperature on electric efficiency), PT collector modelling (PV reference efficiency equal zero) or PV/T collector modelling.

The development of mathematical model and design tool KOLEKTOR has been supported by research project MSM 684077011 “Environmental Engineering” granted by Ministry of Education, Youth and Sports. The experimental validation of the model has been supported by research project CTU 880590 „Experimental validation of mathematical model for flat-plate evacuated solar thermal collector“.

[1] J. A. Duffie, W. A. Beckman, Solar Engineering of Thermal Processes. 3rd edition, Wiley & Sons, Inc., 2006.

[2] D. Y. Goswami, F. Kreith, J. F. Kreider, Principles of Solar Engineering, 2nd edition, Taylor & Francis, 1999.

[3] Solar Energy — The State of Art, ed. by J. Gordon (ISES), James & James, 2001.

[4] TRNSYS 16 release, Mathematical reference, Wisconsin University, 2004.

[5] G. Fraisse, Ch. Plantier, Development and experimental validation of a detailed flat-plate solar collector model, 5th European TRNSYS user meeting, 2003.

[6] J. Koo, Development of a Flat-Plate Solar Collector Design Program, Master Thesis. University of Wisconsin-Madison, 1999.

[7] E. Mathioulakis, K. Vorostopoulos, V. Belessiotis, Assessment of Uncertainty in Solar Collector Modeling and Testing. Solar Energy 66, 337-347, 1999.

[8] Ch. Muller-Scholl, U. Frei, Uncertainty Analyses in Solar Collector Measurement. Proc. of Eurosun 2000, Copenhagen, 2000.

[9] T. Matuska, V. Zmrhal, Software tool KOLEKTOR 2.2, available from http://www. fsid. cvut. cz/~matuskat/kolektor. htm