Как выбрать гостиницу для кошек

14 декабря, 2021

Marco Beccali, Pietro Finocchiaro, Massimiliano Luna, Bettina Nocke

Dipartimento di Ricerche Energetiche ed AMbientali (DREAM) — Universita degli Studi di Palermo

Via delle Scienze bld. 9 — 90128 Palermo, Italy — tel +39091236211 — Fax +39091484425

Corresponding Author: marco. beccali@dream. unipa. it

Abstract

The paper concerns the first monitoring results of a solar DEC system that has been installed at the end of 2007 at the DREAM Department, Universita degli Studi di Palermo, Italy. The system is mainly composed of a desiccant cooling unit for primary air treatments specially designed for application in humid climate, a liquid solar collector system and a radiant ceiling. The system is fully operating since March 2008 and first summer operation results and evaluations are already available. The monitoring results have been aggregated in terms of COP of the desiccant cycle, fraction of the total cooling energy covered by the desiccant cycle and primary energy ratio. They are fairly good and reasonably comparable to the simulation results previously conducted in the design phase. In particular, the monitoring of the system has shown interesting results especially for what concerns the heat recovery from the condenser side of the water chiller used to feed the radiant ceiling and the auxiliary cooling coils. On the other side, some improvements are still necessary, such as air leakages reduction in the heat exchanger, check of some relative humidity measurement points, optimization of set points for auxiliary coils and supply humidity control.

Keywords: Desiccant cooling, radiant ceiling, heat rejection, monitoring results

Several studies show that desiccant cooling system have a limited dehumidification potential for given characteristics of the desiccant rotor, regeneration temperature, flow rates and so on and that auxiliary cooling power for dehumidification is required to fulfil the desired supply air conditions. In addition, the humidity ratio of outside air for the considered location can be very high in summer season (over 20 g/kg). Therefore, particular interest was set to the dehumidification performances of the system. Moreover, the system can be tested in different internal latent load conditions by means of adjustable humidifiers, in order to simulate different occupation patterns.

Another key issue of the set-up is that the heat rejection of the chiller is partially utilized in a heating coil displaced in the AHU return air path for regeneration purposes, allowing a reduction of the required solar field area.

It is known that the energy saving potential of solar cooling systems can be very dramatically affected by higher electricity consumption for auxiliary equipment (fan, pumps, etc) in comparison to the one of conventional systems. With this aim, a detailed monitoring of electricity consumption for ventilation, chiller and auxiliaries was performed.

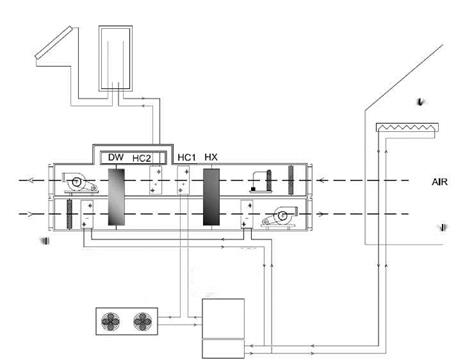

The system is composed of a desiccant cooling unit for primary air handling (AHU) equipped with liquid solar collectors and coupled with a radiant ceiling. The AHU provides fresh air to a room of 450 m3 used as a laboratory for modelling and testing of solar cooling systems. Also the performance of the desiccant AHU in combination with the radiant ceiling can be investigated, with the aim to maximize the specific cooling power of the radiant ceiling in different load conditions. Figure 1 shows the system configuration and its main component.

SOLAR COLLECTORS 22.5 М2

STORAGE 600 LT

RAD ANT

CEILING

EXTRACTED

AIR

RETURN

SUPPLY

A R

OUTS DE

EVAPORATING

Fig. 1. Functional scheme — summer operation

The desiccant cooling unit provides air change and dehumidification by means of a desiccant wheel regenerated both from solar collectors and rejected heat of the chiller. If the humidity ratio and/or temperature set point of supply air is not met, further dehumidification and temperature decreasing can be achieved by means of two auxiliary cooling coils. In particular, the first coil CC1 is utilized for predehumidification purposes, whereas the second one controls the air temperature if the indirect evaporative cooling is not sufficient to reach the desired supply temperature. The radiant ceiling provides to meet the sensible loads.

The control of the AHU in cooling cycle has four operation modes. The system starts in the ventilation mode, where no active air handling is performed, but only the fans are switched on (mode 0). In mode 1, only indirect evaporative cooling is performed by means of a heat recovery wheel HX and the humidifier on the return side. In mode 2, the solar desiccant cooling cycle is operated by means of the desiccant wheel regenerated by the heat coming from solar collectors and the condenser of cooling

The control of the AHU in cooling cycle has four operation modes. The system starts in the ventilation mode, where no active air handling is performed, but only the fans are switched on (mode 0). In mode 1, only indirect evaporative cooling is performed by means of a heat recovery wheel HX and the humidifier on the return side. In mode 2, the solar desiccant cooling cycle is operated by means of the desiccant wheel regenerated by the heat coming from solar collectors and the condenser of cooling

machine. In mode 3, the auxiliary back-up coils are activated to meet the cooling loads in case the desiccant cycle is not sufficient to reach the desired supply air conditions.

As already mentioned, a thermodynamic heat recovery is achieved by means of the condensation heat of the water chiller feeding the radiant ceiling and the auxiliary cooling coils. The heat rejected by the chiller can be used on the return side process to preheat the regeneration air stream [1, 2, 3]. The condensation coil HC1 allows a preheating of the regeneration air stream increasing its temperature of about 12-15°C. An external condenser connected in series to this coil provides for the remaining condensation of the refrigerant of the vapour compression cycle. A further advantage of this configuration is also the good time correlation between the cooling power demand and the heat rejection at the condenser. Further temperature rise up occurs in the solar collectors loop in order to reach regeneration temperatures of 65 — 70°C at the inlet of the desiccant rotor. Due to the higher chilled water temperature required both by the chilled ceiling and auxiliary cooling coils (about 12°C), an increase of the cooling capacity and COP of the chiller can be achieved. A heat storage tank of 0.6 m3 balances the heat produced by the solar system and the heat supplied to the coil HC2. The following table shows some relevant technical data.

|

Table 1: Design data

|

A more detailed description of the plant in terms of control issues and monitoring system can be found in a previous work of the same authors [4].