Как выбрать гостиницу для кошек

14 декабря, 2021

The composition of the developed PV-window is based on state-of-the art technology. The PV — pane is built up as a 3-layer construction with gas filling and a TPS spacer profile.

The composition of the PV-pane and hence a simplified production method are the key elements in reducing the price of the PV-window with up till 20 % or more compared to similar products.

|

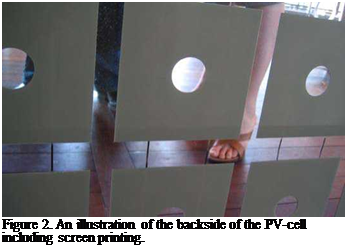

As an additional choice the buyer can buy the PV-window with screen printing, which is used to hide the view from the inside of the building to the unpleasant looking backside of the PV-cell, cf. figure 2.

The screen printing is available in many colors in the RAL color system and the pattern can graphically also fill a part of the spaces between the cells giving possibilities for extended design expressions than just the pattern of the PV-cells.

The degree of freedom in carving and placement of the PV-cells in the pane mentioned in paragraph 2.3 makes it possible for architects to use/place the PV-window anywhere in the building design according to the need of daylight in the rooms. Figure 3 illustrates a typical design of the PV-window — notice the carving in the PV-cells (holes) and screen printing (green).

|

Figure 3. The composition of the PV-window illustrating a typical layout and carving of the PV-cells. 2.5. Composition of the frame The wood-aluminum frame profile “FRAME” from Idealcombi is used for the PV-window, cf figure 4. The frame profile is slim and has a low U-value. |

|

Figure 4. Illustration of the frame profile FRAME from Idealcombi. |

The external wires are hidden inside the wooden frame of the window. The window comes with a plus and a minus plug (hidden in either side of window frame) and enough cable to span a standard joint (hidden in the edge of the frame). Therefore the installation becomes extremely easy and really “plug and play”-like. For broader joints extension cables can be fitted. By-pass diodes are integrated in the frames too and couples out the individual windows if shadowed so that the system still functions brilliantly even when parts are shadowed. The diodes are placed in a box in the frame and can easily be replaced if broken.