Как выбрать гостиницу для кошек

14 декабря, 2021

|

|

|

|

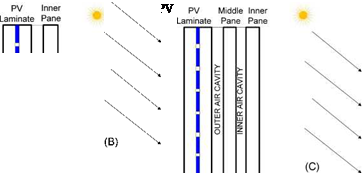

In this study, three configurations of BIPV multi-glazing systems are considered, as shown in Fig. 1. Configurations A and B consist of double-glazed and triple-glazed assemblies where a PV laminate is used as the outer pane. Configuration C is also triple-glazed, but the PV laminate replaces the middle pane and the outer air cavity is naturally vented during daytime to avoid overheating of the cells. The PV laminate in all three configurations is of high PV cells density and the thickness of the different layers are assumed to be 5mm, 2mm and 6mm for the outer pane, combined PV and EVA layer and inner pane, respectively.

1.2. Model Description and Assumptions

The model developed to predict the PV electricity production and the temperatures within the BIPV system consists of a series of energy balance equations performed in the middle of each layer of the assembly. It accounts for thermal capacity, but is one-dimensional. Thus, each layer, including the PV+EVA layer, is assumed to be at a uniform temperature, except in configuration C, where a temperature gradient along the window height is considered in the outer air cavity since it is naturally ventilated. In addition, the following assumptions were made:

• No solar radiation is transmitted to the layers behind the PV because of the high PV density

• The convective heat transfer coefficient at the outer and inner surfaces of an air cavity are the same

• The PV cells work at maximum power point

• The inlet temperature of the air entering the vented air cavity is at ambient temperature