Как выбрать гостиницу для кошек

14 декабря, 2021

A thermotropic layer with an additive concentration of 5 m% was prepared. For the production of the functional material, a dissolution of the thermotropic additive (wax) in the resin was filled into an intervening space located between two glass panes, which were sealed around the edge. Afterwards the mixture was cured by UV-radiation (Ultra Vitalux, Osram GmbH, Mtinchen, GER) for 5 minutes. The film thickness was 800 pm.

2.1. Material Characterization

Solar transmittance in clear and opaque state, switching temperature and switching process of the thermotropic layer was determined by UV/Vis/NIR spectrophotometry. A double beam UV/Vis/NIR spectrophotometer (Lambda 950, Perkin Elmer Instruments GmbH, Uberlingen, GER) equipped with an Ulbricht-sphere (diameter 150 mm) was adapted by a heating stage to adjust the sample temperature. For the given measurement apparatus the radiation passing through the specimen outside a cone of approximately 5° relative to the incident beam direction is defined as diffuse (scattered) component. Hemispheric and diffuse transmittance were recorded at normal incidence in the spectral region between 250 and 2500 nm in steps of 5 K from 25°C to 100°C. Prior to the measurements the sample was maintained at the selected temperature for 10 minutes. The integral solar transmittance was determined by weighting the recorded spectral data in steps of 5 nm by the AM 1.5 global solar irradiance source function, given in Bird and Hulstrom [5]. The data were corrected for radiative losses due to the measurement setup according to Resch et al. [3].

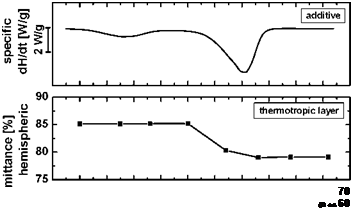

The switching behaviour of the thermotropic layer is determined by thermal transitions of the additives. Thus a comprehensive thermal characterization of the additive was done by Differential Scanning Calorimetry. A thermogram was recorded under static air on a Mettler Toledo DSC823e (Schwarzenbach, CH) in a temperature range between 0°C and 130°C applying a heating rate of 10 K/min. The sample mass was 10 mg.

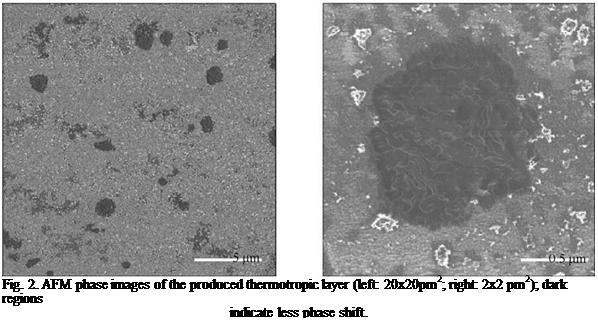

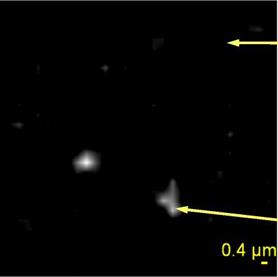

Information as to the morphology of the polymer films was obtained by Atomic Force Microscopy (AFM). AFM was performed in tapping mode (frequency: ~80 kHz) with a MFP 3D (Asylum Research, Santa Barbara, CA, USA). Specific focus was given to the generation of high resolution phase images. Due to the fact that an AFM phase image represents the phase lag between the agitating oscillation and the detected cantilever oscillation, the differentiation between hard (i. e., resin) and soft (i. e., additive) sample areas is possible. Sharpened Si NCH tips with a tip radius <10 nm and an opening angle of 18° were used.

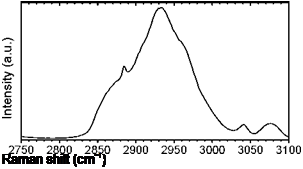

The chemical constitution of the thermotropic layer surface was analysed by Raman spectroscopy using a LabRam HR800 confocal-Raman spectrometer (HORIBA Jobin Yvon GmbH, Bensheim, D). Raman Spectra were obtained by illuminating the specimen through a 100x objective with 514.5 nm excitation from an Ar+ laser. To obtain a spectral resolution of about 1 cm-1 a diffraction grating of 1800 grooves/mm was used. Mapping studies were carried out over the spectral range from 2750 to 3100 cm-1 at 0.5 pm intervals across the sample surface. Raman spectra were averaged over 5 scans,

and accumulation times of 10 s were employed. The Raman map was generated by integrating the relevant additive (wax) peak.

3. Results and Discussion

|

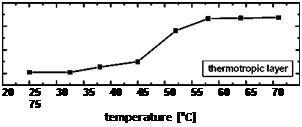

In Fig. 1 the hemispheric and diffuse transmittance of the thermotropic layer is plotted as a function of temperature. Furthermore the switching characteristic of the thermotropic layer is compared to the thermal transition of the additive used. In clear state the material exhibits an excellent hemispheric solar transmittance of 85% with a diffuse fraction of 40%. At a temperature of 45°C the hemispheric transmittance starts to decrease associated by an increase of the diffuse transmittance. This indicates that the layer undergoes a transition from a clear to a scattering state. In general the thermotropic layer shows a rapid and steep switching process within a temperature range of 15 K. Above the switching threshold the hemispheric transmittance decreases by 6% to a value 79%, with a diffuse fraction of 64%. The significant increase of the diffuse transmittance causes a loss of view-through behaviour. According to this switching range and switching temperatures the layer does not provide adequate overheating protection for a solar collector.

50

50

Fig. 1. Thermogram of the additive (top) and hemispheric (middle) and diffuse solar transmittance (bottom) of

the thermotropic layer as a function of temperature.

The comparison of the thermotropic layers switching performance with the additives thermal transitions reveals a good correlation. At the onset of the additives melting peak between 45 and 50°C the hemispheric transmittance decreases and the diffuse transmittance increases significantly.

Subsequently the switching proceeds with the melting of the additive. The thermotropic layer reaches its final scattering state once the additive is in a fully melted state. Besides the melting peak of the additive an endothermic effect at lower temperatures (25-35°C) is observable. This peak can be attributed to a phase transition in the crystalline structure. This endothermic effect leads to a slight change of the solar transmittance. The excellent correlation shows that the switching temperature and process of the thermotropic layer can be tailored by selecting adequate additives.

In Fig. 2 AFM phase images of the thermotropic material are depicted. Dark colours represent a smaller phase lag and bright colours a larger phase shift. According to this, the darker areas represent the softer additive particles and the resin matrix appears bright. This is confirmed by the higher magnification of a dark area shown in the right image, which reveals a superstructure characteristic for the additive used. It is observable that the additive particle dimensions and thus scattering domain sizes range between 0.4 and 2.5 pm.

Figure 3 illustrates a map of the chemical constitution of the surface determined by Raman microscopy along with spectra in the wavenumber range between 2750 and 3100 cm-1. The two presented spectra are representative for the whole surface area. While the top right spectrum characterizes the resin the distinct peak at a wavenumber of 2883 cm-1 of the bottom right spectrum can be attributed to an asymmetric stretching vibration of CH2 groups of the additive. According to the spectra bright colours of the map represent the additive. Additive domain sizes of about 1 pm are detectable. Hence, Raman microscopy confirms the morphological features determined by AFM phase imaging. However, due to the limit lateral resolution of the Raman microscope the domains are less distinct than in the AFM phase image.

|

|

The particle size of the thermotropic layer between 0.4 and 2.5 pm is in good agreement with its moderate reduction of the hemispheric transmittance and the significant increase of the diffuse transmittance. For optimum back scattering efficiency domain diamteres between 200 and 400 nm are required [6]. Larger particles lead to increased diffuse scattering above the switching threshold. Thus to enhance the light shielding performance of the thermotropic layer a significant reduction of scattering domain size is required.

Fig. 3. Raman map (left: 20x20pm2) showing the distribution of additive on the layer surface together with

Raman spectra of a pure resin (top right) and a resin containing the additive (bottom right).

4. Summary and Conclusions

Within the present investigation a thermotropic resin was characterized as to light-shielding efficiency, switching temperature and switching performance. In the clear state the thermotropic layer showed a solar transmittance of 85%. Above the switching temperature of 45°C the hemispheric transmittance amounted to 79%. The diffuse transmittance increased significantly from 40% in the clear state to 64% in the scattering state. The increase of the diffuse transmittance along with the moderate change in hemispheric transmittance was found to be in good agreement with average additive particle dimensions and thus scattering domain sizes of 0.4 to 2.5 pm ascertained by AFM phase imaging and by Raman microscopy. Thus to enhance the film’s reflectance efficiency a significant reduction of scattering particle diameters is required. An excellent correlation between the thermotropic layers’ switching performance and the thermal transition of the additive was ascertained. This enables the production of thermotropic materials exhibiting tailor-made properties by selecting adequate additives.

References

[1] G. M. Wallner, K. Resch, R. Hausner, Solar Energy Materials and Solar Cells, 92 (2008) 614-620.

[2] K. Resch, G. M. Wallner (2007). In Proceedings of ISES SWC 2007, Beijing, China, pp. 541-545.

[3] K. Resch, G. M. Wallner, R. W. Lang, Macromolecular Symposia, 265 (2008) 49-60.

[4] K. Resch, G. M. Wallner (2008). Submitted to Solar Energy Materials and Solar Cells.

[5] R. E. Bird, R. L. Hulstrom. Solar Energy, 30 (1983) 563-573.

[6] P. Nitz, H. R. Wilson (2008). In Proceedings of 2nd Leobner Symposium Polymeric Solar Materials, Leoben, Austria, pp. XIn-1-XIn-6.

|

Acknowledgements

Specialties (Drogenbos, BEL) and Sasol Germany GmbH (Hamburg, GER) for providing the materials.