Как выбрать гостиницу для кошек

14 декабря, 2021

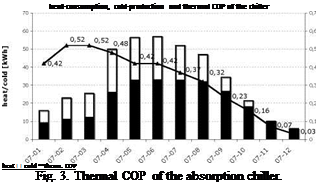

The most important characteristic of a chiller is its coefficient of performance (COP) though it only gives a proportion for the current performance of the machine and does not show its overall performance. Therefore it is better to use the monthly or annually average to rate the efficiency. These values can be calculated from the total heat consumption and the total cold generation of the absorption chiller.

For the year 2007 monthly COP values were calculated from the cold generation and the heat consumption of the machine (see fig. 3). The average thermal COP in 2007 was 0.37.

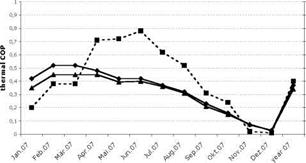

The absorption chiller requires, besides the thermal power demand, also electric energy for operation. In the case of the installed machine this energy is mainly used to supply three pumps, two pumps for the solvent circuit and one pump for the refrigerant medium circuit. The electric connected load of the machine is 3.4 kW, according to the technical specifications. The monitoring results show a permanent electric load of 3.0 kW, regardless of the cold production level. Inclusion of this electric energy consumption into a total COP results in the diagram in figure 4.

The total electric COP in 2007 was 4.0 and the combined thermal and electric total COP was 0.34. Including the parasitic energy used for re-cooling the COP even drops to 0.33.

Heat supply of the absorption chiller, according to the energy concept, aims primarily at solar energy. However, the chiller was operated permanently, not taking into account whether there were solar gains or not. The cold consumption of the building in 2007 was significantly higher than planned. The reason was the higher internal load provided by lighting. Hence the wood pellet boilers provided 81% of the heat for the absorption chiller, compared to 19% solar contribution.

|

|

|

|

|

|

|

The primary energy consumption per produced kilowatt-hour cold can be calculated from the consumption of the different energy sources (wood, electricity) for the heat generation and the COP of the absorption chiller:

|

In summary, the results of the monitoring of the absorption chiller are rather unfavorable. Both, primary energy balance and carbon dioxide emissions are significantly worse compared to the compression chiller, which was also monitored. The main reason for the bad results is almost solely the high parasitic energy of the absorption chiller itself. In the following the reasons for the bad results will be qualified.