Как выбрать гостиницу для кошек

14 декабря, 2021

During the construction of the house, more than 120 thermocouples and other sensors (e. g. electricity meters, etc.) were installed for thermal performance and energy-efficiency assessment. “T” type constantan copper-nickel thermocouples with accuracy of 0.5 °C are used.

1.1. Space heating energy consumption

The envelope of the house is well insulated. Windows are triple glazed with two low-e (emissivity 0.35) coatings and 13 mm Argon-filled gaps. They have an effective thermal resistance of RSI 0.8. The solar transmittance of the windows is 36% and the visible transmittance 71% at normal incidence. The total south facing window area of the ground floor is about 13 m2, which is approximately 15% of the ground floor area. The average effective RSI values for the walls above grade and roof are RSI 6 and RSI 8, respectively. The basement walls have a thermal resistance of

RSI 4, while that of the basement floor is RSI 1.5. The wall thermal resistance values were selected following a sensitivity analysis with the building simulation software HOT2000 [9].

Currently, the house is reserved for monitoring, and sometimes public visiting, so it is not occupied. The space heating consumption recorded will be over-estimated due to the absence of internal heat gains (e. g. appliance and human body). However, with the comparison of the data between cold sunny days and cold overcast days, we can see the contributions to the reduction of space heating energy consumption from passive solar heating. For three continuous days (Fig. 2), during which BIPV/T and ventilated slab did not operate, the heating requirement was 78 kWh for Jan.12th, 60 kWh for Jan. 13th, and 96 kWh for Jan 14th. The average outdoor temperature of Jan. 12th is 5 °C higher than that of Jan. 13th, which was sunny. Another graph (Fig. 3) for Feb. 24th, a perfect sunny day, shows that passive solar space heating and small contribution from BIPV/T heating is able to bring the room temperature 4 °C higher (from 21 °C heating setpoint to almost 25 °C) during the day time even though average outdoor temperature was around 0 °C. The thermal energy stored was adequate to keep the room air temperature above setpoint until 3:00 am of the next day when night-time outdoor temperature was around -5 °C.

|

|

|

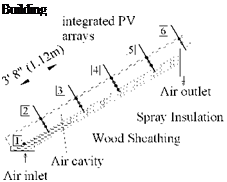

The system was designed to cover one continuous south-facing roof surface for aesthetic and improved roof hygrothermal performance. A 3 kW PV system was installed in the house. It consists of 22 Unisolar PVL-136 laminates attached to the metal roofing (each panel is rated at 136

|

||

W for a total of 22×136 W = 2992 W). The electricity generated by the BIPV system as determined by RETScreen [10] is 3420 kWh/yr for a 30° slope. A gap is created between the metal roofing and the sub-layer behind them as shown in Fig. 4. Outdoor air is used as the heat transfer fluid in an open loop system so as to keep the temperature of the PV panels as low as possible, thus increasing their electricity production. Solar-heated BIPV/T air is used for domestic hot water heating, clothes drying, or VCS thermal mass heating in order of priority.

Air temperatures are measured at all the 6 locations indicated in Fig. 4. Top surface temperatures are measured at all locations except location 1. Back surface temperatures are measured only at location 2, 3, 4, and 5. The thermocouple for top surface temperature is fastened on the nearby wood framing surface. When the top surface (metal sheet) is installed on the roof, the thermocouples firmly touch the top surface.