Как выбрать гостиницу для кошек

14 декабря, 2021

3.3. Low-e coatings

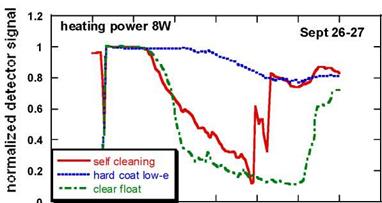

The results of the test box testing of different surfaces are presented as detected light signal versus time. When the signal is high the light beam hits the detector undisturbed and there is no condensation. When condensation occurs the light beam is scattered by the small water drops and the detector signal drops. This is illustrated in figure 2 for three different samples, ordinary glass, low-e glass and hydrophilic (self cleaning) glass. The heating power was dissipated inside the box to generate a realistic heat flow through the glass in order to simulate a real window condition. It can be seen that for the low-e coated glass the signal never dropped, which indicates that no condensation occurred on that surface. For the self cleaning coating and uncoated glass, condensation appeared at the same time, but it disappeared sooner from the self cleaning glass There is also a tendency that the signal for the self cleaning glass is higher than for the uncoated clear float, indicating less scattering. It is, however, not possible to draw any detailed conclusions from the signal level since the illuminated area on the glass surface was very small. In figure 3 the corresponding pane temperatures are shown. The temperature of the self cleaning glass is always the same as for the clear float since the emissivity is the same. It can be clearly seen that the surface temperature of the low-e sample is always a degree or so higher than for the other surfaces with high emissivity, thus preventing condensation.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In the morning of September 12, condensation was formed on both tested windows. At 06:20 the hydrophilic properties had started to work. The water had formed a film rather than drops and the view was only slightly distorted, but far from obstructed as was the case for the uncoated float glass surface. At 07:20 all condensation was completely gone from the hydrophilic surface, while the uncoated surface was still full of condensation. This is illustrated in Fig. 5. The bottom picture shows the two windows in the light of the early morning sun. The difference in appearance is quite dramatic. The outside temperature was 9oC. It is not known at which time the condensation was initially formed.

In the morning of October 31, there was condensation on both windows as shown in Fig. 6. The air temperature was zero. It turned out that the condensation was frozen, and hence sheeting on the hydrophilic surface was inhibited. The view was obstructed through both windows in about the same way. A pattern on the Pilkington Activ surface indicates that water has been running down the surface but was frozen during the process. Exactly how this happened was not investigated.

|

Figure 6. Condensation on the tested windows in the morning of October 31, 2007. Hydrophilic coating to the right |

4. Conclusions

The results of these tests clearly indicate that during around 30 mornings with condensation from September to December, the view through the window with the hydrophilic coating was always better than the view through the window with no external coating, except at the rare occasions when the condensation froze. Moreover the condensation evaporates much sooner from the hydrophilic surface. The low-e coating would probably completely eliminate the problem, but it is also important to make sure the transmittance is sufficiently high. Moreover, the hard coatings tend to be slightly rough and tend to be more difficult to clean than uncoated glass. This could be a major disadvantage with this coating on the external surface. These basic experiment verifies that the external condensation problem “created” by modern glass coating technology (low-emissivity coatings) can also be cured by modern glass coating technology (hydrophilic coatings or low-e coatings). None of the tested surfaces is very expensive so that using them on the external surface should be affordable. They both also would have other benefits than the one tested here and are in fact both marketed for other properties.

The two windows and the test samples used for the investigation were provided by Pilkington Floatglass AB. The low-e hard coating was Pilkington K-glass and the hydrophilic one was Pilkington Activ. Kevin Sanderson, Pilkington European Technology Centre, Lathom, UK, is acknowledged for his involvement in the project.

[1] T. Muneer, N. Abodahab, Frequency of condensation occurrence on double-glazing in the United Kingdom, Energy Conversation and Management, 39(8),717-726, 1990

[2] M. Thyholt, S. Geving, Utvendig kondens pa vindusruter, Norsk VVS: tidskrift for varme, ventilation og sanitaerteknikk, 11, 28-31, 2000 (In Norwegian)

[3] B. Jonsson, Berakning av forekomst av utvandig kondens pa energieffektiva fonster, Technical Report AR 1999:40, SP Byggnadsfysik, Boras (1999) (In Swedish)

[4] H. K. Pulker, Coatings on glass, in: G. Sidall (Ed.), Thin Films Science and Technology, Vol. 6, Elsevier, Amsterdam, (1999)

[5] I. Hamberg, JSEM Svensson, TS Eriksson, CG Granqvist, P arrenius and F Nordin, Radiative cooling and frost formation on surfaces with different thermal emittance: theoretical analysis and practical experience, Applied Optics, vol. 26, no.11, (1987)

[6] A Werner and A Roos, Condensation tests on glass samples for energy efficient windows, Solar Energy Materials and Solar Cells, 91, 609-615 (2007)

[7] A Werner, External Water Condensation and Angular Solar Absorptance — Theoretical Analysis and Practical Experience of Modern Windows, PhD Thesis, Acta Universitatis Upsaliensis, Uppsala, Sweden (2007) ISBN 978-91-554-6830-9

[8] A Werner, A Roos and P Nilsson, Design and evaluation of a detection system for external water condensation on low U-value windows, Sensors and Actuators A, 138, 16-21 (2007)

[9] A Werner and A Roos, Simulation of different coatings to avoid external water condensation on low U — value windows, Optical Materials, 30, 968-978 (2008)