Как выбрать гостиницу для кошек

14 декабря, 2021

E. Yandri[2]* N. Miura1, T. Kawashima1, T. Fujisawa1, M. Yoshinaga2

1Solar Energy Research Group, Department of Vehicle System Engineering, Faculty of Creative Engineering,

Kanagawa Institute of Technology, 243-0292 Atsugi, Japan

2Department of Architecture, Faculty of Science and Technology, Meijo University, 468-8502 Nagoya, Japan

Corresponding Author, yandri@ctr. kanagawa-it. ac. jp

A Hybrid Photovoltaic Thermal (PV/T) collector is an integration of photovoltaic and solar thermal technologies into one system. The idea behind the hybrid concept is that a photovoltaic (PV) cell converts only 6-15% of the incoming solar radiation into electricity and more than 85% of the solar energy is either reflected or converted into heat. PV/T is designed to produce both electricity and thermal energy simultaneously in order to give the highest solar energy conversion efficiency comparing with the separated system into photovoltaic panel and solar thermal collector with the same area. Many researchers have done a lot of efforts to improve its performance by experimentally and simulation analysis. This paper presents the analysis of experimental result for PV/T, focusing on the thermal efficiency with and without electricity generation. The experiment was done during the peak irradiation from 12.00 to 14.00, in the steady state condition. The flow rate is 4 l/min, the inlet water temperatures to the collector is 120C. Especially for this experiment, the result shows that the thermal efficiency of a PV/T is not changed significantly comparing with and without electricity generation. The heat loss for without electricity generation case is a bit higher than without electricity generation case which might influenced by the higher wind speed for without electricity generation case than with electricity generation case.

Keywords: PV/T, thermal efficiency, electricity generation, overall heat transfer coefficient

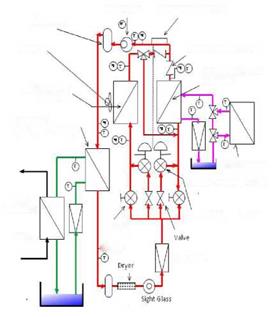

panels and solar thermal collectors. This is the ideal solution if the availability of the roof area is limited. The most common PV/T collector type for low to medium temperature applications follows the sheet and tube heat exchange design shown Fig.1, typically consist of PV module on the back of which and absorber plate (a heat extraction device) is attached. The purpose of the absorber is to cool the PV module which resulted improving the efficiency and to collect the thermal energy produced. The PV plate is fixed on to the absorber plate through a thin adhesive layer. The adhesive layer used is a material with good thermal conductivity, is resistant to extreme temperatures and is extremely improved electrical insulator.

Many researchers and institution have attempted to develop and evaluate the hybrid PV/T collector performance experimentally and analytically. Ito and Miura, experimentally and analytically studied the thermal performance of a PV/T collector that used a partially transparent PV module as a cover [2], [3]. Ito and Miura also reported that the collector efficiency was slightly less while generating power than while not generating power [4]. Othman et al. [5], studied theoretically and experimentally hybrid PV/T solar collector regarding its thermal and electrical performance, used air as a flowing fluid to extract heat from the photovoltaic cells and keep electrical efficiency of it a satisfactory level by the reduction of its operating temperature. The conclusion of this work this work is that is important to use fins as an integral part of the absorber surface in order to achieve meaningful efficiencies for both thermal and electrical output of the hybrid PV/T solar collector. Santbergen and Zolingen simulated various crystalline silicon solar cell configurations found that a standard untextured solar cell with a silver back contact has an absorption factor of only 74%. If a semi transparent solar cell is used in combination with second absorber the total absorption factor can increase to 87%, and if irradiance is absorbed in the back contact, the absorption factor can increase to 85%. They suggested to apply the rough interface in combination with a non standard metal as back contact [6].

The total efficiency of a PV/T npv/t is by adding the thernal efficiency and electrical efficiency Пе1 which can formulated as below

![]() npvt =Ъг +Пе1

npvt =Ъг +Пе1

The thermal effciency of a PV/T collector is defined as the rasio of the useful heat Qth [W] to the product of the aperture area Ac [m2] and the insolation I [W/m2], which is incident on the aperture [1]

![]() Qth

Qth

AI

The useful heat Qth [W] is related to mass flow rate m [kg/s], spesific heat at constant pressure cp [kJ/kgoK], and inlet an outlet temperatures Tn [oK] and Tout [oK] [1]

Qth = mcp (tn — tout) (3)

The efficiency may depend on many factors; collector temperature, ambient temperature, insolation, flow rate, and the incident angle. In order to characterize a collector, one must therefore specify the conditions under which the efficiency has been measured or calculated. One would like to specify the conditions in such a way that the efficiency is defined unambiguously and can be measured reproducibly. This can be accomplished most easily if one bases the effciency on clear sky conditions.

The electrical effciency це1 of a PV/T collector is defined as the rasio of the power generated Qel [W]

to the product of the aperture area A [m2] and the insolation I [W/m2], which is incident on the aperture [1]

![]() The the power generated Qel [W] is related to current Iel [ampere] and Voltage Vel [volt] generated by the solar cell [1]

The the power generated Qel [W] is related to current Iel [ampere] and Voltage Vel [volt] generated by the solar cell [1]

Qei = IV

The common linear formula of the thermal efficiency is [7]:

Пп = Fn O-U ((,, — Ta )/I ] (6)

Where T is transmittance, a is absorptance, the product of та is the optical efficiency no, U is the collector heat loss coefficient, and I is irradiation. Fin is called the heat removal factor, defined by the equation [7]

Where Fm is called the collector efficiency factor that accounts to the resistant of absorber to the ambient Rabs amb and the resistant of front to ambient Rfr amb [7]

b. Schematic experiment set up

|

|

Fig.1. PV/T and experiment set up

2.

|

Fig.2. Thermal efficiency vs irradiation and ambient air temperature.

For with electricity generation case, the irradiation I is decreased approximately from 1000 W/m2 at 12.00 to 770 W/m2 at 14.00. For without electricity generation case, the irradiation I relatively steady approximately 1000 W/m2. The average thermal efficiency i)th for with electricity generation case and

without electricity generation case was relatively about the same. They are 0.5258 for with electricity generation case and 0.5268 for without electricity generation case. Fig.2b shows the comparison of thermal efficiency and ambient air temperature Ta. Although the irradiation I was decreased for with electricity generation case and steady for without electricity generation case, the ambient

without electricity generation case was relatively about the same. They are 0.5258 for with electricity generation case and 0.5268 for without electricity generation case. Fig.2b shows the comparison of thermal efficiency and ambient air temperature Ta. Although the irradiation I was decreased for with electricity generation case and steady for without electricity generation case, the ambient

temperatures Ta for both cases increased during those periods of time. During periods of 12.00 — 14.00, the average ambient temperature Ta was about 11.70C for with electricity generation case and 12.40C for without electricity generation.

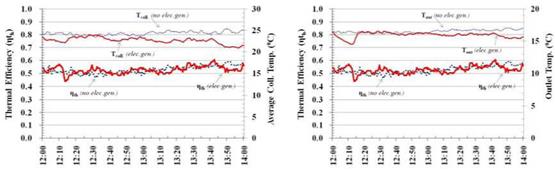

Fig.3a shows the comparison of thermal efficiency nth with the average surface collector temperature Tcoll. The average surface collector temperature TcM for with electricity generation case was unsteady and smaller with average of 23.10C and 24.00C for without electricity generation case. Fig.3b shows the comparison graphs of the thermal efficiency rjth with the outlet water temperature Tout. The outlet

![]()

![]()

water temperature for both with and without electricity generations cases were about the same in the period of 12.15 — 13.00, but from 13.00 — 14.00, they were relatively steady for without electricity generation case and decreased for with electricity generation case. It might be affected by the variation of the irradiation I. The average outlet water temperature Tout for with electricity generation case was about 15.9°C and 16.5°C for without electricity generation.

water temperature for both with and without electricity generations cases were about the same in the period of 12.15 — 13.00, but from 13.00 — 14.00, they were relatively steady for without electricity generation case and decreased for with electricity generation case. It might be affected by the variation of the irradiation I. The average outlet water temperature Tout for with electricity generation case was about 15.9°C and 16.5°C for without electricity generation.

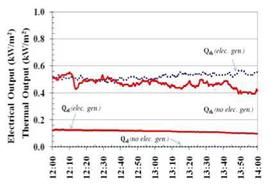

b. Thermal and predicted electrical output Fig.4. Thermal efficiency vs irradiation and ambient air temperature As an effect of the trend of irradiation I, the thermal output Qth and electrical output Qet both with

b. Thermal and predicted electrical output Fig.4. Thermal efficiency vs irradiation and ambient air temperature As an effect of the trend of irradiation I, the thermal output Qth and electrical output Qet both with

electric generation also follow the same trend of irradiation I. It shows that the average thermal

output Qth for without electricity generation case relatively steady about 0.519 kW/m2 and decreased from 12.00 — 14.00 with average about 0.469 kWm2 for with electricity generation.

Fig.5a shows the scatter diagram of thermal output Qth vs (Tavg -Ta) /1 for with electricity generation

and without electricity. Fig.5b shows the scatter diagram of the thermal efficiency nth vs

(Tavg — Ta) / (I — Qel) for with electricity generation and without electricity generation by excluding the

![]() Fig.6a shows the comparison of total loss Qloss tot and the heat loss to ambient Qloss amb of this analysis is calculated by

Fig.6a shows the comparison of total loss Qloss tot and the heat loss to ambient Qloss amb of this analysis is calculated by

Qloss, tot = 1 (1 — nth -Vel )

The total loss Q, is the sum of the top loss Q, , back loss Q, , , and edge loss Q, , ,

loss, tot loss, top loss, back loss, edge ‘

and Eq.(9) can be expressed also

Qloss, tot Qloss, top + Qloss, back + Qloss, edge (10)

![]()

To simplify the analysis, by assuming the ambient air temperature Ta and wind speed Vwind on the top and at the back of collector are about the same, and also neglected the edge loss Qt

|

|

focus to analyse the top loss Qloss t. Because of this experiment used on single cover PV/T, the top loss Qloss o involve are convection and radiation loss from absorber to cover and from cover to ambient and then the top loss Qloss tov can be formulated

![]() q — Ah (T — T

q — Ah (T — T

loss, cov-amb, conv icov conv cov amb

Where. Aabs and Acov are the absorber and the cover area (m2), s is the emissivity (dimensionless, 0.88 for glass [7]), d is the Stefan-Boltzmann constant (5.67×10-8 W/m2K4), Tcbsis the absorber temperature (K), Tcov is the glass cover temperature (K), and Tamb is the ambient air temperature and hcotw is the convective heat transfer coefficient from the cover to the ambient air as a function of wind

velocity Kind

Bay assuming Tsky — Tair — Tamb and Eq.(11c) and Eq.(11d) can be simplified [7]

![]() hamb (Tcov Tamb ) hconv (Tcov Tamb ) + Scovd(Tcov Tamb )

hamb (Tcov Tamb ) hconv (Tcov Tamb ) + Scovd(Tcov Tamb )

Knb is the effective heat transfer coefficient for both convection and radiation which has value of 20W/m2 for 3m/s wind speed and 30W/m2 for 6m/s wind speed [7]. To simply analysis,

assuming the radiative and convective from absorber to cover ( Qtoss, abs-cov,.rad and Qloss, abs-cov, conv ) more

or less the same for with electricity generation and without electricity generation, and the analysis

focus on the radiative and convective loss from absorber to cover ( Qioss, cov-amb, rad and Qloss, cov-amb, conv X

Loss energy ratio (LER) is the ratio of total loss Qloss tot divided with irradiation I and formulated in

LER — Qosso /1 (13)

|

Fig.6. Energy loss and wind speed

Fig.6b shows also the wind speed Vwind of with electricity generation was lower than the wind speed Vwind of without electricity generation. The average wind speed Vwind of with electricity generation was about 0.3 m/s and 1.1 for without electricity generation. Using Eq.(11.c), the radiative heat loss

from cover to the ambient Qloss cov-amb rad for without electricity generation relatively as same as with electricity generation. Using Eq.(11.d), the average convective heat loss from cover to the ambient Qioss cov-amb conv for without electricity generation was about 0.119 kW/m2, higher than the average

convective heat loss from cover to the ambient for with electricity generation was about 0.075 kW/m2. It proved that the wind speed has a significant effect to the ambient loss.

Especially for these experiments, some parameters, like irradiation, ambient temperature, were not so closed each other, they did not change significantly the thermal efficiency. It means that the thermal efficiency for with electricity generation is relatively as same as without electricity generation. The total loss Qloss especially for the heat loss to the ambient Q0ss cov-amb increased as same

as the wind speed increased. The analysis shows that the thermal efficiency formula in Eq.(6), (7) and (8) did not influence much to the parameters of collector heat loss coefficienct U, heat removal factor Fin, and collector efficiency factor Fm.

The support of “High-Tech Research Center Project for Private Universities: matching fund subsidy from MEXT, 2007-2011” for this research is appreciated.

[1] Duffie, J. A, Beckman, W. A., Solar Engineering of Thermal Processess (third edition), John Wiley & Sons, Inc. Hoboken, New Jersey

[2] Ito, S., Miura, N., Solar Air Collector Using Photovoltaic Modules as the Cover, Proceedings of ISES Solar World Congress, Budapest, Vol. 3, pp.271-276, 1993

[3] Ito, S., Miura., Usage of a DC Fan Together with Photovoltaic Modules in a Solar Air Heating System, Proceedings of ISES Solar World Congress, Gotheborg, Sweden, 2003.

[4] Ito, S., Miura, S., Performance of Photovoltaic and Thermal Hybrid Air Collectors, Proceedings of ISES Solar World Congress, Orlando, USA, Paper No. 1349, 2005

[5] Othman, M. Y., Yatim, B., Sopian, K., Bakar, M. N.A., Performance studies on a finned doublepass photovoltaic-thermal (PV/T) solar collector. Desalination 209 (2007) 43-49

[6] Santbergen, R., van Zoelingen, R. J.Ch., Modeling the thermal absorption factor of Photovoltaic / hermal Combi Panels. Heat Set 2005, Grenoble, France [3]