Как выбрать гостиницу для кошек

14 декабря, 2021

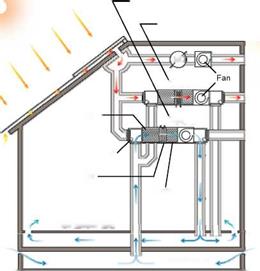

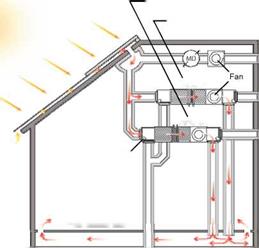

The solar desiccant cooling system is composed of two air handling units and the operation mode is switched. Therefore, the switching time point is important.

At first, when the collected hot air temperature is 40 degrees C, a air handling unit is started in regeneration operation. The other air handling unit is not operated yet. When the regeneration operation is finished, the operation mode of the air handling unit is changed to the dehumidification mode and the other air handling unit is started in regeneration operation. From the finish of the regeneration process at the one air handling unit, the solar desiccant cooling system is operated in regeneration process and in dehumidification cooling process at the same time while the operation mode is switched. When the relative humidity of the primary desiccant

|

|

module outlet air is 10%, it is judged that the regeneration is finished. In addition, the regeneration time limit is set for the cloudy days.

module outlet air is 10%, it is judged that the regeneration is finished. In addition, the regeneration time limit is set for the cloudy days.

Fig. 2. Outdoor and indoor view of field test building.

![]() Dehumidification cooling process

Dehumidification cooling process

Regeneration process

MD

AHU A

|

||

Foundation pit

Fig. 3. Solar desiccant cooling operation in summer.

In winter, this solar desiccant cooling system is used for the solar space heating system. Therefore, this solar thermal system is the solar space heating and ventilation system in winter and the solar desiccant cooling and ventilation system in summer. The solar space heating system is operated for the collected hot air temperature of 30 degrees C in winter.

A. Preisler1*, T. Selke1, L. Siso[6], A. LeDenn3, R. Ungerbock4

1 arsenal research, Sustainable Energy Systems, Giefinggasse 2, 1210 Vienna, Austria 2 AIGUASOL, C/ Roger de Lluria 29, 08009 Barcelona, Spain 3 TECSOL, 105 av Alfred Kastler, 66004 Perpignan, France 4 CONNESS, Conrad von Hotzendorferstrasse 103a, 8010 Graz, Austria Corresponding Author, scientific. comm@,eurosun2008.org

Abstract

The Sixth Framework Programme (6th FP) of the EC aims to cover community activities in research, technological development and demonstration (RTD). The Specific Supported Actions (SSA) focus on dissemination of previous research results, contribute to strategic objectives and prepare future RTD activities. The ROCOCO project is a case of SSA in the 6th FP, which objective is the reduction of cost of solar cooling systems. The technology of solar cooling consists of production of air-conditioning or refrigeration using the renewable energy of solar systems, particularly, the solar thermal applications.

ROCOCO aimed at the cost-competitive deployment of solar-assisted air conditioning technologies instead of conventional operated ones in order to promote energy efficiency more actively.

Consequently, the overall objective was to identify European wide cost reduction potential for Solar Cooling systems, based on the collection of dissemination from existing installations, estimation of cost tendencies by setting up comparable applications with transient simulations [1] related with costs, know-how of RTD and inclusion of industrial participants.

Keywords: solar cooling, solar-assisted air conditioning, cost reduction potential

1. Content and methodology

The activities carried out to reach the objectives have been the following:

Monitoring market and technology:

— Monitoring of market and technologies with a focus on collection available data from existing solar cooling installations and scan of research studies, literature and patents

Building sectors and applications:

— The preparation of technology and market matrix (T & M) using transient simulations [1] for obtaining energy demand values for different areas of applications: hospitals, hotels, office buildings, trade commercial centres and residential buildings.

— Setting up models of solar cooling installations using transient simulations [1] for most promising applications (absorption, adsorption and desiccant) to analyse the energy performance.

— Pre-selecting the technology and application pairs with the highest feasibility and cost reduction potential

— Collecting information from the market about costs of equipment, energy prices and maintenance services costs.

— Assessing the costs for investment (material, installation and planning) and operation (auxiliary energy, water consumption and maintenance) to analyse cost tendencies, in comparison with conventional system.

RTD Gaps, Potentials and Topics:

— Definition of the ideal specifications for components used for solar assisted cooling as solar collectors, absorption machine, adsorption machine, hot water tank, cold water tank, hydraulics, air-conditioning devices and desiccant evaporative cooling

— Identification of cost reduction potential of each component by assessment of impact for material costs, installation costs, cost for design and planning, operation costs and maintenance costs

— Cost reduction potential of energy performance, component investment costs, energy prices, engineering costs, maintenance costs and subsidies for total annualized over costs (life cycle costs) of solar cooling towards conventional cooling

— Set up of three scenarios (baseline scenario, ambitious scenario, accelerated scenario) for target prices of solar assisted cooling and evaluation through lifecycle costs and return on investment (ROI)

— Setting up questionnaires for component manufactures to get their assessment of cost reduction potential divided in R&D activities, grey energy, assembly processing, store costs, selling and after sale service

— Expert workshops for market analyses and development of market penetration strategies 2

|

1st International Congress on Heating, Cooling, and Buildings — 7th to 10th October, Lisbon — Portugal /

table 1. Models of building representing the market |

This paper only gives some results of the most promising cases of the T & M matrix (technology x building sector) for cost reduction in solar cooling1. The figure used is the cost of primary energy unit saved [€/kWhl, that is the relation between the total annualized costs of a solar cooling plant and the total primary energy saved. This combines the effect of the costs and the performance of the system.

The different cases with absorption systems can be grouped depending in certain ranges of increase of primary energy costs over reference, as it is shown in table 2.

|

Costs of PE savings |

Austria |

Spain |

France |

Outside EU |

|

< 0.15 |

none |

— Hospitals and hotels in Madrid, Malaga and Barcelona |

— Hotels in Perpignan (B3, B2) |

— Hospitals and hotels in Esfahan |

|

0.15 — 0.25 |

— Hospitals in Graz |

— Hospitals in Bilbao — Trade in Madrid — Office in Malaga |

— Hospital in Lyon, Nantes and Perpignan — Hotels in Perpignan, Lyon, Nantes and Melun — Trade in Perpignan and Nantes (D3) |

— Offices, trade and residential in Esfahan — Hospital in Merida |

|

0.25 — 0.35 |

— Hospitals in Wien — Hotels in Graz and Wien |

— Office in Madrid — Trade in Bilbao — Residential in Malaga |

— Trade in Perpignan (D1) and Lyon (D2) — Office in Perpignan (C3) — Hospital in Melun (A3) |

— Office and trade in Merida |

|

> 0.35 |

— Offices and trade in Wien, Graz, Innsbruck |

— Residential in Bilbao |

— Offices Lyon and Melun — Trade VEE (D1) in Lyon and Nantes |

none |

|

table 2. Costs of primary energy savings. AB+FPC. Summary by country and building type |

The different cases with desiccant systems can be grouped depending in certain ranges of increase of primary energy costs over reference, as it is shown in table 5.

1 Whole public part of ROCOCO results

1 Whole public part of ROCOCO results

http://www. arsenal. ac. at/products/products en gt cs de. html

|

1st International Congress on Heating, Cooling, and Buildings — 7th to 10th October, Lisbon — Portugal /

table 3. Costs of primary energy savings. DEC+FPC. Summary by country and building type |

3. Conclusion

A full supervisory control and data acquisition (SCADA) system with over 700 measuring and control points was implemented in the Almeria building so that the entire HVAC system as well as the thermal comfort parameters could be precisely supervised and controlled in the whole building. The system was also design bearing in mind that this building would be a research platform and that as many parameters as possible should be monitored. The main monitoring and control points are listed below.

Temperature measurements

• Throughout the air distribution system (e. g., ATUs, Inductive units situated in the zones)

• Throughout the water distribution system (e. g., before and after every element connected to the water system, inside the absorption heat pump and the cooling tower, after every 3way valve)

• Throughout the building (e. g., in every zone, and height distribution in one zone only) Humidity measurements

• In the ATUs, in order to control the properties of the air entering the building

• In one of the offices Pressure measurements

• In some points of the water distribution system Flow rate measurement

• By know, there is no need for flow measurement because the water loops operate at constant flow rates on all circuits

• In future they will operate at variable flow rate, so on every water distribution circuit flow rate will be measured by means of inline ultrasonic flow-meters (soon-to-be installed)

Energy consumption

• By now, only the overall electric energy consumption is monitored

• In the future, individual energy consumptions of pumps, heat pumps, fans, … will be monitored as well.

These measurements are centralized by the SCADA system and can be shown to every building user by means of a purpose-made interface which allows people to consult all measured temperatures, control the temperature setpoint in their room, and also allows users with supervisor privileges to control all parameters for the entire HVAC system. The main controlling points used by the system to regulate the building’s air conditioning are the following:

• Heating/Cooling equipments working mode (e. g., winter mode for heating or summer mode for cooling)

• Heating/Cooling equipments state (e. g., switched on or off depending on which equipment we want to be producing heating/cooling energy)

• Pumps’ state and working point (e. g., switch on/off distribution circuits and control the Heating/Cooling rate by varying fluid flow rate on these circuits)

• 3-way valves’ opening state (e. g., control the distribution of hot and cold water over the distribution circuits in order to obtained the desired heating or cooling effect while optimizing thermal energy use)

The goal of the implement SCADA system is to help maximize the contribution of passive/low energy techniques with regard to conventional heating/cooling techniques.

1.2. The adoption of the condensation coil

An improvement of the energy and exergy performance of a standard DEC system may be achieved if an additional heating coil is installed on the regeneration side, after the recovery wheel and before the traditional heating coil; in this paper it will be referred to as “condensation coil”. The amount of thermal energy recoverable from the “condensation coil” is limited by the temperature of the gas coming out of the compressor, which can be assumed as high as 75°C, in a chiller working with R-407C and a condensation pressure around 2 MPa. The saturation temperature of R-407C in the same operating conditions is as high as 45°C, but this potential thermal drop of 30°C can not be always exploited, as the temperature of the air coming out of the recovery wheel can be higher than 45°C, as shown in Tab.3.

|

Table 3. Inlet air temperature to the condensation coil (point F, see Fig. 1)

|

Fig.3 shows the results of the analysis as the percentage improvement achievable by using a condensation coil with respect to the corresponding standard DEC cycle. The results get better as both the regeneration temperature and the solar fraction decrease, as in this case the temperature of point C (see Fig. 1) increases, thus determining an increase of the temperature tF (see Table 3). As previously explained, this reduces the recovery potential of the condensation coil, which causes the limitation of the performance improvement to only 5% if solar energy is not used, against the 12% obtained with a regeneration temperature as high as 70°C.

Furthermore, the advantage of installing a condensation coil in a solar assisted DEC system seems not to be high, as the coil limits the potential left to the solar system.

|

10 |

|

0 0.2 |

|

Solar fraction |

|

0 0.2 |

|

0.4 0.6 0.! Solar fraction |

|

0 0.2 |

|

0.4 0.6 0. Solar fraction |

|

5 |

|

0 |

|

1 |

Fig. 3. Improvements due to the adoption of a condensation coil

Actually, there is a different way of looking at these results, which is that the condensation coil allows a reduction of the collecting surface needed to achieve the same results in terms of overall energy savings; an economic analysis is required to decide whether to integrate the system with solar section.

The phase-out of some categories of substances by the International Protocols has stimulated the research on more environmentally friendly fluids. Before considering a fluid as a potential candidate for ORC systems, a market investigation should be done to know if the fluid is market available and cheap. To give an idea of the prices of some fluids, the information in the Table 4 below was taken from a supplier in Athens, Greece.

|

Fluids |

Price (Euro/kg) |

|

FREON 22 DU PONT |

3,33 |

|

SUVA 134A DU PONT |

6,34 |

|

SUVA 401B DU PONT |

10,85 |

|

SUVA 407C DU PONT |

6,63 |

|

SUVA 123 DU PONT |

11,76 |

1.1 Potential and legislation framework

So far, microgeneration has been largely underestimated as a potential alternative way of energy conversion. In Portugal it started to gain the deserved recognition and attention very recently. Microtrigeneration, the wide category of microgeneration, demonstrated by Polysmart subprojects 6a and 6b, is in the way for consumer autonomy. Locally produced heat, cold and power, fulfilling the individual combination of local needs can maximize synergies and strongly reduce CO2 emissions.

When compared to large-scale power production in terms of unit costs, microgeneration also performs well, with numerous comparative studies indicating its competitiveness [2]. Furthermore, since power is generated at the point of use the usual grid-based costs such as supply, transmission and distribution costs are avoided. Although requiring a different infrastructure from the one in use for the current centralised system, microgeneration starts to make economic sense in the long run if the modernisation and replacement costs associated to the existing transmission and distribution networks are considered.

The microgeneration policy in Portugal (D. L. 363 -2/Nov/2007) allows power delivery to the grid with subsided feed in tariffs for solutions until 3,68 kW based on solar power, wind power, hydro power and biomass cogeneration. Microtrigeneration should also be considered in further revisions of the present legislation.

On the other hand, buildings thermal efficiency plays a major role on local energy demands. There is specific legislation related to the subject (D. L. 78/2006; D. L. 79/2006; D. L. 80/2006), but a better conciliation with microgeneration, namely, microtrigeneration policy is desired.

It is clear that mass market microgeneration has potential to significantly supply the energy demand. Nevertheless, the rules surrounding energy trading, grid connection, planning and subsidies were developed having in mind much bigger applications, presenting serious barriers to local microcogeneration or microtrigeneration solutions.

Polysmart demo subprojects 6a and 6b are a step forward and, we hope, a significant contribution for the next regulatory framework for local energy conversion largely understood, as power, heat and cold.

So, Polysmart subproject 6b running on biodiesel is planned to be grid connected as a cogeneration unit under the present regulatory microgeneration framework. The revenue from the power delivered to the grid should be enough to face 50% of fuel costs. Subproject Polysmart 6a, running on LPG, is not under present microgeneration regulatory framework. At least, the next regulatory framework should include natural gas and LPG as privileged fuels, when substituting diesel in residential heating boilers.

Moreover, microgeneration, cogeneration or trigeneration have wider benefits as they actually act as a catalyst for cultural changes in consumer attitude, and provide evidence of the important impact that local energy production has on attitudinal and behavioural changes towards energy use. Therefore, micro generation is not only a serious form of efficient energy supply contribution, but also a solution in bridging the gap between energy efficiency and consumer behaviour and responsibility.

Considering the present experience in Portuguese PV microgeneration, grid connection is not a problem for microtrigeneration solutions. Electrical protections, such as maximum and minimum voltage, current, frequency, and island networking prevention are available on a wide range of equipments. Meanwhile, if needed, when stabilized standards, such as VDE 0126 are not applied, additional electrical protections could be included on project.

The key for microgeneration technologies to reach maximum impact lies on price to the consumer falling to competitive levels. A number of regulatory and policy changes are required to allow this to happen. Particularly, the government must set binding national targets in order to create the

necessary confidence for developers to fund mass production manufacturing capacity. There are a number of individual policy measures that would also assist the expansion of the microgeneration sector including: granting permitted development status for some approved microgenerators, detailed consideration of the export reward mechanism that allows payment for surplus electricity (when not stand alone systems) that spills on to the grid, inclusion of microgeneration within the Building Regulations and the Sustainable Buildings Code, simplifying access to ‘green energy certificates’, and the introduction of new policies for micro generators producing heat and cold. Buildings would become “micro-power stations” instead of passive consumers of energy.

Converting energy without heat dissipation at the point of use, i. e. using at least 90% of the fuel productively, is extremely efficient when compared to power stations that typically waste over 60% of the total energy released by burning fossil fuels in heat loss, and a further 10% in transmission and distribution losses.

1.2 Promising applications

From a technical-economic point of view microtrigeneration plants are more adequate for applications with permanent occupation and thermal needs.

In the last decade the number of dwellings in Portugal increased 17,2%. On the other hand, around 32% of the total number of family houses (detached and semi-detached) built in Portugal each year (22.143 including refurbishments) have four or more bedrooms [3], meaning that there is a reasonable potential for pCHCP systems in the residential sector.

The tourist accommodation sector in Portugal can also be considered to have an interesting potential for this kind of application, mainly for the hotels, apartments and resorts segments which represent around 80% of the overall capacity of the 2.031 establishments found in the country [4].

Another promising application which is growing due to population aging is the case of the nursery homes. The great energy consumption in hot water production for laundry application, constant along the year in these institutions, is important for thermal energy consumption without breaks and is also interesting to combine with solar, taking profit of the abundant resource in summer.

This kind of institution has high running costs and in most cases short budgets hence an energy efficient trigeneration solution could help solving these serious managing difficulties.

Sports halls and small office buildings may also be a good example of application.

Simulation results of a variation in ambient conditions and regeneration temperature are assessed with regards to the above described exergetic framework.

The dependence of exergy destruction and exergetic efficiency on ambient humidity ratio is given by Fig 6. As the dependence on ambient temperature is almost equivalent, it is not shown here. The exergy destruction rises with increasing ambient temperature as well as increasing ambient humidity ratio. The change in exergy destruction is dominating in the adsorption and pre-cooling stages in which the driving potential for heat exchange (temperature difference) and adsorption (pressure differential) is increasing, leading to higher irreversibilities in both heat and mass transfer processes. In contrast, the exergetic efficiency is a function characterized by a maximum. This maximum is due

to opposite curvature of the exergetic product and the exergetic input. This suggests that the system performs best in certain climatic conditions for a given set of regeneration temperature, mass flow rates and building return air conditions.

|

Fig 6: Exergetic performance dependent on rnamb, at Fig 7: Exergetic performance dependent on Tamb=32.0°C and Treg=85°C regeneration temperature, inlet conditions as in table 1 |

|

The mainly used technologies for solar cooling systems with small-scale cooling capacity (< 30 kW) are absorption and adsorption cooling. Single-effect absorption chillers with the working pair water/lithium bromide and ammonia/water respectively are generating cold over a closed, continuous cycle. The ammonia/water absorption chillers could generate evaporator temperatures down to -60°C, which are useful for industrial cold processes. Using water as refrigerant the evaporator temperature is limited to temperatures above the freezing point. In absorption chillers the refrigerant (water or ammonia) is absorbed by a liquid sorbent (lithium bromide or water) as shown in Fig. 1. In the directly or indirectly solar powered generator with high heating temperatures, the refrigerant is desorbed from the solution. This generates a high refrigerant vapour pressure, which is sufficient to condense the refrigerant in the condenser. After evaporation, the refrigerant vapour is absorbed in the solution which is cooled in the absorber. The solution is pumped to the generator by a solution pump where it is regenerated and throttled back to the absorber. The heating temperatures for desorption are between 70 and 120°C according to the technology. Basically absorption chillers are used as central air-conditioning systems with decentralised fan coils or cooled ceilings.

At adsorption chillers the refrigerant water is adsorbed on a solid sorbent like silica gel among disposal of latent heat on the surface (Fig. 1.). The latent heat decreases to zero with increasing addition of water molecules, then only evaporation heat has to be dissipated. The desorption of the stored water and the pressure generation for the condensation is already caused by low heating temperatures of 55 to 70°C, so that this technology is especially appropriate to the application of solar energy. The closed adsorption chillers are generating cold water of minimal 5 to 6°C through the periodical cycle. These chillers can also be used as central air conditioning systems with decentralised fan coils or cooled ceilings.

D. Mugnier [10]*

1 TECSOL SA, 105 avenue Alfred Kastler, BP 90434, F-66004 PERPIGNAN, France

* Corresponding Author, daniel. mugnier@tecsol. fr

Abstract

This poster is aimed at presenting a fast pre-design method based on a succession of tools assembled in a future unique computer application.

The method is based on individual existing tools coming from European and national R&D projects (a specific acknowledgment to the Fraunhofer ISE). It is based as well on the feed back of European solar cooling experiences through expert engineering companies. The IEA Task 38 framework, through Subtask B (Custom-made systems for large non-residential buildings and industrial applications), has permitted to TECSOL to build-in this method with numerous international expert contributions.

First, a check list leads to determine or select if the technology really match the environment of the project (loads, meteorology, requirement, topologic barriers, etc…).

When most of the arguments of the list meet a positive answer, the method shows to the user the specific requirements on some parameters of the project: materials, building, installer, exploitation staff and monitoring of the installation. Advice on the best and most adapted technology is given thanks to a decision scheme.

Then, the user can easily and roughly simulate the targeted building and make some calculation from the boundary conditions, thanks a simple method based on ratios.

At this stage, the user can have a good picture of the technical and economical aspects of solar cooling technology for his project, through a user friendly presentation of the results.

The presented user-friendly method should permit to help planners, architects and building owners to evaluate whether a solar assisted cooling system can be integrated in their building project, and under which conditions and at which investment and operating costs. This represents therefore an helpful way to break one of the barriers for the integration of Renewables in the Built Environment.

Keywords: solar cooling, predesign tool, software

Some precautions must particularly be taken at different levels of the project, to have the best conditions to implement such a technology in real conditions : type of targeted building, environment, geographic situation, load profile, pre-design of the system, design, commissioning, and monitoring. Due to the early development stage of the solar cooling technology and the complexity of the system design, no easy-to-play and fast pre-design method is for the moment available to planners, architects and building owners. The goal is to provide them a tool to assess whether the project is feasible or not, at a technical level as well as at an economical one.

2. Description of the method

The maximum performance for solar cooling systems (solar COP) with Flat Plate collectors (FP) happens at temperatures between 70-80°C and corresponds to 35%. Using Vacuum Tube Collectors (VTC), the solar COP increases by 9% for a temperature range of 80-90°C. The use of a double effect absorption chiller with VTC leads to a solar COP between 60-65% for a temperature range of 110-135°C.

4.1 Influence of collector tilt angle and orientation

Regarding inclination, as expected, the production is optimised for a tilt angle corresponding to latitude-50 (optimised for all year collection). A solar system, if installed in a horizontal plane, has a penalization on the range of 2-32% (absolute values) — with lower penalization for places with lower latitudes and buildings with more representative cooling loads — if installed in a vertical wall the penalization lays in the range of 25-60% (absolute values).

Deviations up to 60° relative to South, reduce solar fraction between 3 and 10% (absolute values).