Как выбрать гостиницу для кошек

14 декабря, 2021

E. Ienei 1*, M. Voinea1, R. Lates1, L. Isac1, I. Visa1, A. Duta1

1 The Centre: Product Design for Sustainable Development, Transilvania University, Eroilor 29, 500036,

Brasov, Romania, Tel. 004-0740054297, Fax 004-0268410525,

*email: e. purghel@unitbv. ro

Abstract

Selective surfaces are required to improve the solar collectors’ efficiency, thus the conversion of solar radiation into thermal energy. Performing coatings should have high solar absorption coefficient (as>0.9) in the wavelength range of 0.3-2.5 pm and low emittance (s< 0.1) for wavelength higher than 2.5 pm; high durability absorbers must be obtained using low amounts of chemicals, as thin films deposited on large surfaces, in environment-friendly processes with low energy consumption.

The aim of this paper is to test the efficiency of two new thin film composite absorbers deposited on aluminium and copper substrates. The absorbers, based on either copper oxides/nickel oxides or alumina/nickel oxides and coated with an antireflective layer: titania, were integrated into a laboratory collector and their efficiency was measured for different incidence angles. The results proved that their efficiencies are comparable, with better results for the absorber with copper substrate. The optimum incident angle (from the horizontal plane) for collectors with this type of absorbers is 10-30 degree.

Keywords: flat plate collector, solar absorbers testing, spray pyrolysis, incident angle.

The climate changes and the increasing energy consumption are one of the mankind major problems. Each product needs to be re-designed as to have a minimum environment impact, on all its life cycle steps. Not only the payback time has to be considered in the product development, but also the energy payback time.

In a sustainable future, buildings with low energy consumption must be developed. This can only be achieved by implementing saving/renewable energy systems. The solar collectors can be efficiently used for heating/cooling applications. Still, technical improvements have to be made in order to identify more cost efficient solutions considering the embodied energy and materials. The solar absorber, the active part of a photo-thermal device, is the most expensive component of the system; therefore new methods should be developed to decrease the cost, without a major effect on its performance. Generally, the absorber plate is made of a highly thermal conductivity metal (Al, Cu) coated with a spectrally selective surface, with maximum absorption across the solar spectrum and minimum emission in the infrared region, [1-4]. Absorbers must be obtained using a low amount of chemicals (non-toxic), on large surfaces in order to minimize the energy consumption and to protect the environment.

The first selective coatings were based on black paints [5]. Because the temperature of the absorber surface is above ambient temperature, the surface re-radiates some of the heat back to the

surroundings. This loss mechanism is a function of the surface emittance of the low-temperature, long-wavelength (infrared) radiation. Therefore, these coatings have high absorption in the short — wavelength radiation, but also high long wavelength radiation loss from the surface [6]. On the other hand, the nowadays state of art selective coatings are rather expensive due to the complex deposition methods and/or the obtaining process are involving toxic (by) products.

The aim of this paper is to test the efficiency of two new, low cost, black nickel based absorbers deposited on aluminium and copper substrates. The solar absorbers were integrated into a laboratory flat plate collector and their functional parameters were measured for different incidence angles. The results, in terms of heat and efficiency are discussed in this paper.

The work in IEA-SHC Task 39 includes the study of polymeric materials in solar thermal applications from a polymer-engineering point of view [17]. An overview of selected absorber designs of polymeric materials is presented in Table 1. Depending on the absorber and the manifold, five different concepts are shown for the design of commercial polymeric solar absorbers: (1) pipe+pipe, (2) panel+pipe, (3) panel+endcap, (4) film+pipe, (5) panel. While the concepts (1) to (4) are based on extruded absorbers and injection moulded manifolds, which are connected by mechanical fixing, gluing or welding, the panel concept is based on blow — or roto-moulded components with integrated semi-finished fittings. Advantages of the panel concept are a reduced number of processing steps, the use of semi-finished components (fittings) and the possible realization of more complex absorber designs. However, panel concepts (5) are limited in the length of the absorber. An important prerequisite for concepts (1) to (4) is the use of similar materials, especially thermoplastics, for the absorber and the manifold. Compared to absorbers with pipe geometry, absorbers with flat surfaces exhibit a better functionality/material-ratio (less material is required) and a better applicability of functional layers.

A large potential for innovative development of components and systems by using polymers is expected in the solar thermal industry as successfully demonstrated in other industry sectors. A short presentation of various polymer applications in solar collectors, heating system designs, overheating protection and the analysis of different absorber designs from a polymer-engineering point of view is given. A complete, updated review with evaluation and experiences will be prepared as a final deliverable of IEA-SHC Task 39. It will additionally include the state of the art of polymeric applications in small, medium-sized heat — and seasonal thermal stores and patented ideas. The official Task 39 website is: http://www. iea-shc. org/task39.

Acknowledgements — The lead of Subtask A of IEA-Task 39 "Polymeric materials in solar thermal applications" is supported by ENOVA SF and the Research Council of Norway (RENERGI).

|

Table 1. Characterisation of different absorber designs from a polymeric engineering point of view [17]. |

|

1) Pipe-pipe absorber (EPDM) |

2) Pipe-pipe absorber (thermoplastics) |

3) Panel-header |

4) Film-pipe |

5) Panel |

|

|

Blustration, |

|||||

|

example |

QuickTime™ and a TIFF (Uncompressed) decompressor are needed to see this picture. |

||||

|

Source: G. Wallner |

Source: Solar-Flex |

Source: FAFCO |

Source: [18], Sarnafil |

Source: Texsun |

|

|

Materials |

Thermoplastics, elastomers |

Thermoplastics |

Thermoplastics |

Thermoplastics |

Thermoplastics |

|

Design |

Absorber: extruded (EX) elastomer Manifold: injection moulded (IM) thermoplastic |

Absorber: EX thermoplastic pipe Manifold: IM thermoplastic pipe |

Absorber: EX thermoplastic panel Manifold: IM thermoplastic header |

Absorber: EX thermoplastic film Manifold: IM moulded fittings |

Absorber: blow — moulded thermoplastic panel Manifold: blow — moulded with IM parts |

|

Components |

2 components: pipes, header; size and format: module length variable, width limited; |

2 components: pipe is semifinished; size and format: variation in length; |

2 components: size and format: length variable, limited in width; |

Film, fittings are semi-finished; size and format: length variable, width limited; |

Film, fittings are semi-finished; size and format: limited in length+width |

|

Production process |

3 steps: EX: pipes IM: header mechanical joining |

3 steps: EX: pipes IM: header mechanical joining |

3 steps: EX: panel IM: header joining: welding |

2 steps: EX + rolling: film joining: welding |

2 steps: EX: film, BM: panel joining: — |

|

Coating |

after EX difficult |

after EX difficult |

after EX: easily |

after EX: easily |

after EX |

|

Additional functions |

Snap connectors in IM — header |

Snap connectors in manifold and pipe |

Snap connectors in manifold and pipe |

Snap connectors in fittings |

Snap connectors in panel |

|

Investments |

medium: EX, IM low: joining |

medium: EX, IM low: joining |

medium: EX, IM, welding |

medium (EX) |

low (mould) |

|

Quantities |

medium |

medium |

medium |

high |

medium |

|

Auto- matisation |

low: joining high: components |

low: joining high: components |

medium: joining high: components |

high |

high |

|

Labour |

intensive |

intensive |

less intensive |

less intensive |

low |

|

Application |

pool heating, unglazed |

pool heating, unglazed |

pool heating, unglazed; DHW and space heating, glazed |

Pool heating and DHW preheating, unglazed; |

pool heating, unglazed; DHW heating, glazed |

|

EX: Extrusion, IM: Injection moulding, BM: Blow moulding; |

[1] ESTTP, 2006. Solar Thermal Vision 2030, 1st version of the vision document for the start of the European Solar Thermal Technology Platform (ESTTP), http://www. esttp. org, May 2006.

[2] EREC, 2007. Renewable Energy Technology Roadmap up to 2020. European Renewable Energy Council, 2007.

[3] M. Fawer. Sustainability Report-Solar Energy 2006, Bank Sarasin & Co. Ltd., Dec. 2006

[4] W. Weiss, I. Bergmann, G. Faninger (2008). Solar Heat Worldwide — Markets and contribution to the Energy Supply 2006, Edition 2008, IEA-Solar Heating and Cooling Programme, April 2007. AEE INTEC, Gleisdorf, Austria.

[5] Sources: b) www. estif. org, c) http://leifi. physik. uni-muenchen. de/web_ph10/umwelt- technik/16sol_kollektor/arten. htm.

[6] J. D. Burch. Polymer-based solar thermal systems: Past, present and potential products. Society of Plastics Engineer’s Annual Technical Conference 2006, Charlotte, North Carolina, May 2006.

[7] C. G. Gebelein, D. J. Williams, R. D. Deanin (eds.) (1982). Polymers in Solar Energy Utilization, American Chemical Society Symposium Series, ISBN 0-8412-0776-3.

[8] M. Kohl, G. J. Joergensen, S. Brunold, B. Carlsson, M. Heck, K. Moller, Durability of polymeric glazing materials for solar applications, Solar Energy 79, (2005) 618-623.

[9] F. Rusch et al. Ageing Performance of Collector Glazing Materials — Results from 20 Years of outdoor Weathering.

In Proceedings of the EUROSUN 2008 Conference, October 7-10, 2008, Lisbon, Portugal.

[10] M. Kohl, B. Carlsson, G. J. Joergensen, A. W. Czandera (eds.), (2004). Performance and durability Assessment — Optical Materials for solar thermal systems. Elsevier Ltd., Oxford, UK.

[11] N. Rumler. Untersuchung von Kunststoffkollektoren hinsichtlich Uberhitzung im Stillstandsfall. Master HTWK Leipzig and University of Oslo, 2007.

[12] Wavin B. V. Solar collector with plastic tubes for transfer medium — and heat-exchangeable overheat protector to open housing wall for convection cooling. Patent, Publication number: NL8105671, Publication date: 1983-07-18.

[13] K. Resch, G. M. Wallner, Thermotropic materials for overheating protection of solar collectors. In Proceedings of the EUROSUN 2008 Conference, October 7-10, 2008, Lisbon, Portugal.

[14] K. Resch, G. M. Wallner, Overheating protection with thermotropic resin systems: Effect of material structure and morphology on light-shielding efficiency. In Proceedings of the EUROSUN 2008 Conference, October 7-10, 2008, Lisbon, Portugal.

[15] K. Resch, R. Hausner, G. M. Wallner, Modeling of an all-polymeric flat-plate collector with thermotropic overheating protection. In Proceedings of the EUROSUN 2008 Conference, October 7-10, 2008, Lisbon, Portugal.

[16] R. Griessen, M. Slaman. Solar collector overheat protection. Patent number: P6017675NL; Patent/IP status: filed.

[17] H. Schobermayr, G. M. Wallner. State-of-the-art absorber designs — Evaluation from a polymer engineering point of view. Presentation at the IEA-SHC Task 39 Meeting in Oslo, Norway, April 29-30, 2008.

[18] G. Zweifel, S. Brunold, L. Delineau, R. Friedlin, S. Keiser. SARNASOL — Das innovative Dachsolarsystem,

1. Schweizerisches Status-Seminar “Energie und Umweltforschung im Bauwesen, ETH Zurich, September 7-8, 2006.

The horizontal temperature distribution of the ventilated collector is shown in Fig. 3. From the temperature difference of the three sensors respectively at the top and the bottom of the absorber plate can be concluded that the horizontal variations are small.

These temperature variations are correlated with periods of high wind speeds measured. Along the vertical axis the absorber temperature is significantly lower in the bottom than in the top with a maximum difference of 42 K. Almost 35 K of the temperature increase occurs over the lower part of the absorber. This fraction varies to some extent with the tilt angle but generally a larger temperature difference was observed in the lower half than in the upper half [10].

For the reference collector the temperature increase over the lower half of the absorber is typically 25 K while the increase over the upper half is 5 K.

1.2. Sensibility of slit opening and tilt angle (set-up A)

The effect of the size of the slit aperture and the collector tilt angle on the temperature reduction relative to the reference collector was investigated.

|

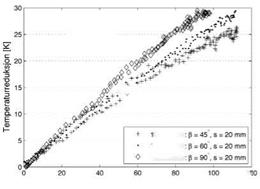

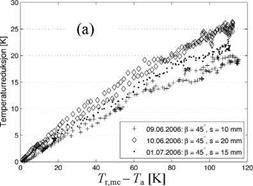

The temperature reduction (of the ventilated relative to the reference collector) is displayed in Fig. 4 as a function of the temperature difference Trmc-Ta. The reduction is given for measurements with slit apertures of 10, 15, 20 mm and tilt angles of 45, 60, 90°. In Fig. 4 (a) the tilt angle is constant at 45° and it is clearly shown that increasing slit apertures result in higher temperature reductions.

|

|

In Fig. 4 (b) the slit aperture is constant while the tilt angle is varied. Here the temperature reduction is largest when the collector tilt angle is 90°. Although the same maximum temperature reduction is obtained with tilt angles of 90° and 60° it occurs at different temperatures of the reference plate.

Fig. 4. Temperature reduction of the ventilated — relative to the reference collector as a function of the

temperature difference Trmc — Ta for slit apertures of 10, 15, 20 mm and tilt angles of 45, 60, 90°; [set-up A]

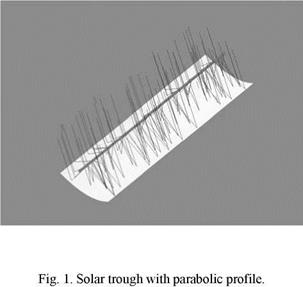

During the last decade we developed solar collectors from optical design, deeply analysed using ray tracing simulations, to realisation and test. Several optical layouts have been considered: linear concentrators, as well as, lens configurations with increased complexity from simple parabolic collectors to lens mirror combinations [1-7]. Our solar concentrators are designed to be applied in the Photo Voltaic sector or in the thermal field.

During the last decade we developed solar collectors from optical design, deeply analysed using ray tracing simulations, to realisation and test. Several optical layouts have been considered: linear concentrators, as well as, lens configurations with increased complexity from simple parabolic collectors to lens mirror combinations [1-7]. Our solar concentrators are designed to be applied in the Photo Voltaic sector or in the thermal field.

The studies presented in this paper analyse a trough collector with parabolic profile, whose characteristics and performance have been examined by ray tracing simulations. The major components of the solar trough are linear mirror and linear absorber in Fig. 1. The linear parabolic mirror

concentrates the sunlight over the absorber represented by a metal pipe, surrounded by a glass tube. The configuration parameters considered in this paper are:

■ Linear parabolic mirror

— Focal length: f = 780 mm.

— Dimensions of collector aperture:

— Width W = 1.8 m;

— Length L = 5 m.

■ Linear Absorber

— Dimensions of metal pipe:

— External diameter D = 50 mm;

— Length L = 5 m.

— Dimensions of glass tube:

— External diameter G = 70 mm;

— Thickness T = 2 mm;

— Length L = 5 m.

The first study describes an original methodology to reproduce rigid deformations of the linear parabolic mirror. Successively it analyses how much these mirror deformations affect the energy collected by the solar trough. The second study examines the interactions between mirror deformations, misalignment and tracking errors. The optical characteristics considered in this paper are: mirror edge deformation, collection efficiency, misalignment angle and acceptance angle.

K. Resch1* and G. M. Wallner2

1 Polymer Competence Center Leoben GmbH, RoseggerstraBe 12, A-8700 Leoben, Austria

2 Institute of Materials Science and Testing of Plastics, University of Leoben, A-8700 Leoben, Austria

Corresponding Author, resch@pccl. at

Abstract

Within this paper thermotropic hydrogels, thermotropic polymer blends and thermotropic systems with fixed domains are reviewed with respect to their capability to prevent overheating of solar collectors. As to their switching ranges (77% for thermotropic hydrogels, 52% for thermotropic polymer blends and 25% for systems with fixed domains) the functional layers are well suited for solar collector applications. For an all polymeric flat-plate collector with twin — wall sheet glazing and black absorber thermotropic hydrogels, thermotropic polymer blends and TSFD would limit maximum absorber temperatures to 75, 90 and 125°C, respectively. This would allow for the use of cost-efficient plastics as absorber materials. However, thermotropic materials have not yet been developed systematically for the application in solar thermal systems with corresponding switching temperatures and properties to resist the demanding environmental conditions especially for prolonged periods.

Keywords: overheating protection, thermotropic hydrogels, thermotropic polymer blends, thermotropic systems with fixed domains

The application of cost-efficient plastics as absorber materials for all-polymeric solar collectors requires appropriate overheating protection. A feasible way to limit stagnation temperatures is the reduction in optical gain especially by the use of thermotropic layers [1]. Thermotropic glazings are actively switchable layers which permit the light and energy flux to be adapted dynamically to temperature conditions within the collector. In the past various thermotropic systems for active daylight control in transparent facades have been developed and investigated mainly [2,3]. Within this paper existing thermotropic systems are discussed with respect to their capability to prevent overheating of solar collectors.

Kollektorfabrik started in June 2006 to incorporate the must-haves of a highly efficient collector and the don’ts of a stagnation vulnerable solar thermal system. In this process we questioned the common water based solar heat transfer medium and put our attention on air.

1.1 Solar fraction

To raise the total share of solar thermal energy, there are different possibilities:

• New fields of solar thermal usages could be implemented. Basically, every process that is in need for heat up to 130 °C can be satisfied or supported by a solar thermal application. Often processes need a huge amount of thermal energy, which leads — if supported by solar thermal systems to huge solarfields with all their necessities. Except for uncovered absorbers for low temperature applications there is not really a wide range of products which can be used for large scaled collectorfields. A field of air collectors is not limited in size, since an inconvenient stagnation behaviour cannot occur.

• The solar fraction of every single application could be raised. The chart in figure 1 is well known as the demand and offer of a solar thermal system for a private household in the run of a year. A big collectorfield enhances the solar fraction but exceeds the heat demand for domestic hot water in summer. This can cause trouble if, for instance due to lack of knowledge, no measures are taken to deal with the energy overrun.

In fact the size of the collector area alone has a minor impact on the system costs. Even systems that support space heating, often cut the size of the collector area due to the maximum content of the installed storage tank and not only to the maximum of the installable collector area.

The solar fraction of an application therefor is often not a question of the affordable collector area, but how to deal with the risks of energy overrun in the summer period and the associated cost of implemented measures.

|

Fig 1. Demand, offer and overrun of energy for a household with a solar system which supports spaceheating. |

Another approach is to increase the ratio between aperture and absorber area. This ratio is called geometrical concentration ratio. CPCs (Compound Parabolic Concentrators) are applied, because these optical concentrators have no focal point. Thus tracking can be avoided in combination with concentration ratios lower than two.

Figure 2 shows a stationary, non-evacuated CPC-type collector without a vacuum and with a concentration ratio of 1.5. It is made up of riser tubes centred in symmetrical CPC valleys with two asymmetrical CPC valleys for the headers. The absorber is V-shaped (inverted V). The collector has only two inlet/outlet connections and has a minimum back insulation of 3 cm. There

|

is enough distance between the glass and the top of the absorber for the collector to be provided with anti-convective barriers such as a Teflon® foil.

The research institute INETI (Lisbon, Portugal) was involved in the development. The collector is available on the market and has an operating temperature level of 110°C, e. g. suitable to operate an absorption cooling machine.

The p. roposed test method is similar to the way according to ISO 9806-1 (1994), and basically, the main difference is that except the steady-state measurement there are some integral tests included to determine the overall thermal performance. It is a strict test condition to satisfy all of parameters for steady-state measurement, when solar irradiance would be influenced by cloud. So the whole process for measurement would be a long period and expensive. In the case of the actual utilization, the surrounding condition always is exposed in a dynamic mode. In order to simplify this in this proposal and broaden the test scope, during the day test continuous measurements should be operated whatever the fluctuation of solar radiance and a more widened range for temperature and flow rate. Through this kind of measurement a set of comprehensive data that would access to actual needs to some extents could be provided successfully.

The test determines steady-state efficiency of all-glass evacuated tube solar collectors in order to evaluate the thermal performance and consequently comparison with other kinds of solar collectors. The average global thermal efficiency, the relationship between the increments of outlet temperature and total solar energy on the collector plane, and the relationship between the increments of instantaneous efficiency and total energy on the collector plane are also determined. Moreover, manufacturers can optimize their products or design solar water heating system depending on the actual test results.

This test is a systematic and comparatively comprehensive test for determining the thermal performance of water heating solar collectors. The thermal behaviour is characterized by means of

whole collector tests using a “black box” approach. In the whole test process it contains that the experiment of determining the steady-state thermal performance of solar collectors, the experiment of determining the instantaneous efficiency of solar collectors, and the experiment of determining the thermal performance during the whole day operation.

M. Meir1*, J. Buchinger2, S. Kahlen3, M. Kohl4, P. Papillon5, J. Rekstad1, G. Wallner6

1 University of Oslo, Department of Physics, P. O. Box 1048, N-0316, Oslo, Norway

2) Arsenal Research, Giefinggasse 2, A-1210 Vienna, Austria

3) Polymer Competence Center Leoben, Roseggerstrasse 12, A-8700 Leoben, Austria

4) Fraunhofer Institute for Solar Energy Systems, Heidenhofstr. 2, D-79110 Freiburg, Germany

5) CEA-INES, BP 332, 50, avenue du Lac Leman, F-73377 Le Bourget du Lac, France

6) University of Leoben, Institute of Materials Science and Testing of Plastics, Franz-Josef Str. 18, A-8700

Leoben, Austria

* Corresponding Author: mmeir@fys. uio. no

Abstract

The state of the art of polymeric materials in solar thermal applications is reviewed in IEA — SHC Task 39. The present status with regard to solar thermal collectors is summarized. Examples of favourable solar heating system — and solar collector designs of polymeric materials are illustrated. Overheating protection opens for the application of commodity plastics in glazed collectors. Various absorber types are compared from a polymer-engineering point of view.

Keywords: Polymeric materials, solar collectors, IEA-SHC Task 39, plastics;

Approximately 40% of the final energy demand in the EU25 member states is used for low temperature heating and cooling — a share, which is in principle easily accessible with solar thermal technology [1]. However, the fraction of energy use covered by solar thermal is nearly negligible and still below 0.05% in the European countries [2]. In the Sustainability Report 2006 by Bank Sarasin [3] an annual growth rate of 25-30% of newly installed global collector capacity is expected up to 2010. Conventional solar collector systems are based on materials (e. g. copper) with limited availability. The material supplies will not be large enough to cover up for the expected growth in solar thermal installations. These issues demand the introduction of new materials, of which polymers seem to have a strong preference in all respects. Polymers reveal a large cost — reduction potential due to mass production, reduction in weight, freedom in structural and functional design and the potential to lead to a breakthrough for solar thermal energy production.

Polymeric collectors had a market share of 19% of the worldwide solar heating capacity in operation in 2006 [4], which are almost exclusively unglazed absorbers for swimming pool heating. The US represents the largest market for polymeric pool absorbers with a power production of

19.2 GWth in operation at the end of 2006. Pool absorbers are applicable in the low temperature range. In order to meet the requirements from the market for heating applications in the medium and high temperature range, the introduction of new polymeric materials and technology is essential. New materials can only be applied if the service-life is comparable to those in conventional products. Task 39 is a collaborative effort in the International Energy Agency’s Solar Heating and Cooling Programme, which brings together solar thermal — and polymer experts from research institutions and industry working on these challenges. IEA-Task 39 is divided in three Subtasks,

A: Information, B: Collectors and C: Materials. An on-going effort is the preparation and update of a database on existing applications, prototypes and patents with regard to polymers in solar thermal applications. The present work gives a brief overview limited to solar thermal collectors and integrated storage collectors.

The collector design is modular in steps of 4 m length and consists of 11 primary mirror rows with a width of 0.5 m each. The primary mirrors are made of tempered white glass with silver backside coating. They are mechanically bent to concentrate the sunlight on a tubular vacuum receiver (SCHOTT PTR® 70) with secondary CPC concentrator 4 m above the mirror field. The secondary is an aluminium mirror in CPC shape (Alcan Singen / Alanod). Each mirror row is moved by an individual drive connected to an embedded Linux unit with astronomical control software.

|

Table 1. Geometric parameters of the collector

|

Optical Performance parameters were derived out of Raytracing calculations, thermal performance parameters could be deducted from reported measurements [2]. For practical use we defined a site independent number of thumb for the peak capacity.

|

Table 2. Performance parameters of the collector

|

|

Figure 1. PSE linear Fresnel Process Heat Collector in Bergamo, Italy. |

Robur has installed two of their NH3/H2O absorption chillers in a modified version with a heat exchanger for pressurized water. These can be seen in Figure 1 on the right hand side of the picture. The collector is aligned with the building, which is not exactly north-south oriented, but turned 7.6° towards SE-NW.