Как выбрать гостиницу для кошек

14 декабря, 2021

Integrated storage collectors and thermosiphon systems are typically installed in climates without freezing during the winter season. The storage is the collector (ICS), Fig. 1 (c), or is closely connected to the collector (thermosiphon system), Fig. 1 (b). These systems have compact designs, are normally on-roof mounted and a relatively easy supplement or replacement of a domestic hot water (DHW) boiler. Here the introduction of polymeric materials contributes to considerable reduction of weight and opens for innovative, functional designs and shapes (see examples, Fig. 9).

2.1 Flat plate collectors and favourable system design

Europe has a sophisticated market for different solar thermal applications, as systems for DHW preparation or combined solar heating systems for DHW preparation and space heating (combisys- tems) in single — and multi-family houses, hotels and large-scale plants for district heating [3]. Due to the heat loss such collector systems require a collector cover (glazing).

Already during 1977-1985 substantial R&D was performed in the US on polymeric solar thermal collectors, first of all for solar DHW systems [6, 7]. Presently there exist few commercial glazed collectors with polymeric absorbers. These are mostly designed for low-pressure systems, which are open vented and have pure water without antifreeze additives as heat carrier. Depending on the

application polymeric absorbers have different design criteria to the solar collector system than conventional, metal-based absorbers; some designs have a built-in overheat/freezing protection mechanisms for the solar collectors, e. g. drain-back technology, ventilation or other designs to avoid thermal stagnation or freezing of the heat carrier in the solar loop.

For polymeric absorbers of commoditive or engineering plastics the operative system temperature should be as low as possible in order to minimize thermal load for the polymer, favour long service-life and high overall system efficiency. Glazed absorbers of high temperature performance plastics with spectrally selective coatings are not in the market yet, but might/will contribute to serve the retrofit market of small solar DHW systems.

|

|

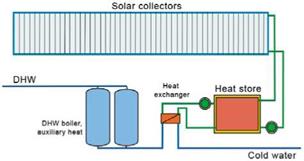

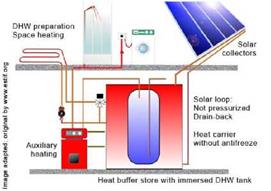

Examples of hydraulic system designs, which are favourable for the application of glazed polymeric collectors, are — among others — solar heating systems with large DHW demand (sport centres, hospitals, nursing homes, etc., see Fig. 2 (a)); further solar combisystem with large heat store (~100 l/m2 collector area), low temperature heating system (floor/wall heating), avoiding intermittent heat exchangers between solar loop, storage volume and heat emission system (Fig. 2 (b)).

(a) (b)

Fig. 2. Examples of hydraulic system designs, which are favourable for the application of polymeric collec-

tors; (a) solar DHW system covering large DHW demand and (b) solar combisystem.

With collector parameters and the measurement data for irradiation, ambient temperature, inlet and outlet temperatures of the collector, it is possible to calculate a theoretically expected collector power. The comparison of expected and measured collector power is shown in Figure 4.

Additionally as a result of Raytracing calculations the theoretical optical efficiency was plotted over time in the same graph. The oscillation of the efficiency is produced by the shadow of the receiver, which moves from mirror row to mirror row. At 14:45 the shadow moves out of the mirror field, so that the optical efficiency theoretically increases up to 51% at 15:37 on that day.

|

Table 3. simulation parameters

|

|

|

The design of the trestle aimed at the possibility of rotating the parabolic trough about a single axis automatically (east-west or north-south) and about the second axis manually. The possibility of the manual tracking allows the reduction of the IAM (incident angle modifier) by positioning the parabolic trough with the ideal angle to the sun, especially during the experimental phase.

As identifiable in Fig. 2, the trestle is built up of a frame base of square steel bars with the dimensions of 2 m x 2 m, which gives the construction the necessary stability. In the middle of the frame base, a vertical square bar is fixed. With a bearing at the top, the vertical square bar holds the carrier for the collector body. The whole construction is mounted on concrete blocks to stabilize it and to avoid slipping. Its weight is about 60 kg without the concrete blocks. The main disadvantages of the trestle are the vast dimensions, the high mounting expenditure, the high material usage and the restricted possibility to build several parabolic troughs in a row.

As mentioned above, the collectors’ rotation axis is equal to its caustic line, which means that the trough rotates about the absorber system. For this reason the absorber always remains in a fix position, so that the inlet and outlet pipes can be assembled inflexible.

The bearing of the trough comprises of a combination of a fixed bearing at the bottom and a loose one at the top. They are mounted with the carrier, so that the trough rotates between the carriers’

blades. The absorber system is inserted into the trough from the outside by sliding it through the fixed bearing, which is designed with an appropriate opening. The absorber system is positioned between the bearings on a cushion to protect the sensitive glass pipe.

If several parabolic troughs are arranged in a row it is not possible to change the absorber system of one trough in the middle of the row in the case of damage. That is a big disadvantage in view to the handling since it would be necessary to remove several parabolic troughs to change one absorber.

Planned optimization: It must be possible to arrange several collectors in a row. For this reason the possibility of a manual tracking about a second axis will be relinquished, so that automatic tracking will be feasible only about one axis (east-west or north-south). In a north-south arrangement angles of rotation of 160°, respectively in an east-west arrangement of 80°, will be necessary.

Between two collectors in the row, there will be only one post, at which both collectors are fixed from each side. To reduce costs, the 1 m high post will be designed of standardized steel I-section, which is zinc coated.

The bearing concept will be assembled of seven components which will meet the following demands: bearing of the collector (static and dynamic load), support of the absorber system, transference of torsion moments from one collector to the next collector in a row and compensation of linear thermal expansions to avoid restraints. In addition, the bearing must balance the draft of the collector body (see above) to make a rotation about its axis possible. Mainly because of the last mentioned reason, there is no product on the market which meets the mentioned demands. Because of this it is necessary to develop a new concept.

To compensate the above mentioned side plates’ draft of 4°, all components are screwed on according slant mounting plates, which are also screwed on both side plates of the collector. The bearing itself consist of a bearing-seat, in which a sliding bearing is forced. Due to the open inner diameter of 65 mm, the connecting pipes of the absorber system fit through this opening. The rotation of the collector will be around a hollow shaft, which sticks in the sliding bearing and will simultaneously be used as a support for the absorber system. The hollow shaft is designed with a flange, so that it remains in its fixed position by screwing it at the post. To transfer the torsion moment, the slant mounting plates are connected by stiffening components between the collectors.

J. Scheuren*, M. Kirchner

Institut fuer Solarenergieforschung Hameln (ISFH), Am Ohrberg 1, D-31860 Emmerthal, Germany

Corresponding Author, j. scheuren@isfh. de

Tel: ++49-5151/999-523, Fax: ++49-5151/999-500

Abstract

The main characteristic parameters to describe the stagnation process of solar-thermal collector arrays are the steam-producing power (SPP), the steam spread (StS) in the pipework of the solar circuit and the resulting steam volume (SV). For a proper dimensioning of the expansion vessel and a protection of the temperature-sensitive components in the collector circuit a reliable prediction of both the SV — and StS-value is necessary. Based on a total of 210 outdoor stagnation experiments a model to predict the main characteristic stagnation parameters of collector arrays has been developed. The experiments were carried out between 2003 and 2007 using three different collector types with a total of eight different connection and installation variations. With this empirical model, it is now possible to predict SPP, StS and SV in the solar circuit for collector arrays of up to 30 m2.

Keywords: Solar Thermal Collector, Stagnation, Expansion Vessel, Steam-producing power, SPP, Steam Spread, Evaporation

Solar heating systems with high solar fractions, which provide both domestic hot water and space heating energy, are regularly under stagnation conditions during summer. The evaporation of the heat transfer fluid can lead to a considerable spreading of hot steam into the solar circuit. As a consequence the collector loop components and the heat transfer fluid are exposed to a high thermal impact, which may lead to an accelerated ageing and damage. For the further development of solar thermal combi-systems with high solar fractions it is necessary to understand and control the stagnation process of large-scale collector arrays. In this paper the impact of the stagnation process to the solar circuit will be quantified and an easy to apply calculation method will be presented.

In 2001/2002 the AEE INTEC (Gleisdorf, Austria) has investigated single collectors and collector arrays with favourable draining behaviour regarding their stagnation behaviour [1]. In the subsequent work, carried out at ISFH in the years 2004 to 2007, collector arrays with critical evaporation behaviour are measured in detail. In addition a vacuum-tube collector array is being investigated. In [2] first results of the outdoor stagnation experiments at ISFH have been published.

The main characteristic parameters to describe the stagnation process of solar-thermal collector arrays are steam-producing power (SPP), steam spread (StS) in the pipework of the solar circuit and the resulting steam volume (SV). For a proper dimensioning of the expansion vessel a reliable prediction of the SV is necessary. In 2007, in the course of a research project supported by the

German Federal Ministry for Environment, Environmental Protection and Reactor Safety (BMU), we have now quantified the impact of the stagnation process on the solar circuit and developed a model to predict the main characteristic stagnation parameters of collector arrays up to 30 m2.

The heater saves about 17 MJ of energy per day. There are 300 clear days in a year at Jodhpur and, therefore, solar water heater can be used for 300 days per year, accordingly, calculations have been made of energy savings per year in relation to different fuels, and payback periods have been computed. The economic evaluation and payback periods have been computed by considering interest rate = 10%; maintenance cost = 5% of cost of the solar heater, and inflation rate in fuel prices and maintenance cost = 5 % per year. Cost of the heater is Rs. 8,000.00 (Euro 1.0 = Rs

60.0) . The cash flow of the heater with respect to different fuels has been carried out and it has been found that the cash flow is maximum with respect to fuel coal and minimum with respect to kerosene. The payback period is least, i. e. 1.42 yr, with respect to coal and maximum, i. e. 3.72 yr, with respect to kerosene (The cost of kerosene is highly subsidised). The payback periods are in increasing order with respect to fuel: coal, electricity, firewood, LPG, and kerosene. The estimated life of this solar water heater is more than 15 years. The shorter payback periods suggests that the use of ICS solar water heater is economical. The use of integrated collector storage solar water heater will conserve substantial amounts of commercial and non-commercial fuels, which are consumed for obtaining hot water.

Integrated collector storage (ICS) type solar water heater can provide 100 litres of hot water at an average temperature of 57.3o C that can be retained to 43.0o C till next day morning when cold water temperature was 17.0o C. The efficiency of the heater has been found to be 61.3%. The heater saves about 17 MJ of energy per day. Cost of the heater is Rs. 8,000.00 (Euro 1.0 = Rs

60.0) . The cash flow of the heater with respect to different fuels has been carried out and it has been found that the cash flow is maximum with respect to fuel coal and minimum with respect to kerosene. The payback period is least, i. e. 1.42 yr, with respect to coal and maximum, i. e. 3.72 yr, with respect to kerosene (The cost of kerosene is highly subsidised). The payback periods are in increasing order with respect to fuel: coal, electricity, firewood, LPG, and kerosene. The estimated life of this solar water heater is more than 15 years. The shorter payback periods suggests that the use of ICS solar water heater is economical. The use of integrated collector storage solar water heater will conserve substantial amounts of commercial and non-commercial fuels, which are consumed for obtaining hot water.

[1] IMD, Solar Radiation Atlas of India, India Meteo. Department, New Delhi. 1985.

[2] D. J. Close, Solar Energy, 6 (1962) 33-40 .

[3] J. I. Yellot, R. Sobotka, Trans. ASHRAE, 70 (1964) 425.

[4] C. L. Gupta, H. P. Garg, Solar Energy, 12 (1968) 163-82.

[5] K. S. Ong, Solar Energy, 16 (1974) 137-48.

[6] N. M. Nahar, Energy 5 (1984) 461-464.

[7] G. L. Morrison, N. H. Tran., Solar Energy, 33 (1984) 515-26.

[8] G. L. Morrison, J. E. Braun, Solar Energy, 34 (1985) 389-405. ‘

[9] M. Vaxman, M. Sokolov, Solar Energy, 37 (1986) 323-31.

[10] N. M. Nahar, and J. P. Gupta, Energy Conversion and Management, 27 (1987), 29-32.

[11] Norton, B., Probert, S. D. and Gidney, J. T., Diurnal performance of thermosyphonic solar water heaters — an empirical prediction method’, Solar Energy, 39 (1987) 251-65.

[12] N. M. Nahar, Int. J. Ambient Energy, 9 (1988) 149-54.

[13] N. M. Nahar, Int. J. of Energy Res. 16 (1992) 445-452.

[14] N. M. Nahar, Energy Convers. & Mgmt. 32 (1991)371-374.

[15] N. M. Nahar, Int. J. of Energy Research 16 (1992) 445-452.

[16] N. M. Nahar, International Journal of Renewable Energy, 26 (2002) 623-635.

[17] N. M. Nahar, International Journal of Energy and Buildings, 35 (2003) 239-247.

[18] B. J. Brinkworth, Solar Energy, 71 (2001)389-401.

[19] I. Tanishita, Present status of commercial solar water heating in Japan. ISES Conf., Melbourne, Paper 2/73,1970.

[20] S. J. Richards, D. N. W. Chinnery, A solar water heater for low cost housing. NBRI Bull., 41, CSIR Res. Rept. 237, South Africa, 1967.

[21] H. P. Garg, Solar Energy, 17 (1975) 167-172.

[22] N. M. Nahar, Energy Conversion and Management, 23(1983) 91-95.

[23] N. M. Nahar, J. P. Gupta, J. P., Int. J. of Energy, 12(1988), 147-153.

[24] N. M. Nahar, J. P. Gupta, Applied Energy 34 (1989)155-162.

[25] D. Fairman, H. Hazan, I. Laufer, Solar Energy, 71(2001) 87-93

[26] Y. Tripanagnostopoulos, M. Souliotis, Th. Nousia, Solar Energy, 72(2002)327-350.

[27] M. Smyth, P. C. Eames, B. Norton, Solar Energy, 75 (2003) 27-34.

[28] M. Souliotis, Y. Tripanagnostopoulos, Solar Energy, 76 (2004) 389-408.

[29] A. Madhlopa, R. Magawi, J. Taulo, Solar Energy, 80 (2006) 989-1002.

The collector heat loss coefficient UL was determined with the ventilation flap in operation for the experimental set-up B and data of Sept. 9 and Sept. 14. The dimensions of the slit aperture, the flap’s sensitivity setting and the collector tilt angle are given in Fig. 7. Fig. 7 shows that UL

increases for larger AT from the interval 5.4 — 6.8 W/(m2 K) to the interval 8.2 — 9.3 W/(m2 K) due to the self-triggered opening of the ventilation flap. Here, a constant collector heat capacity of Ce=5 kJ/(m2 K) was chosen. The experimental set-ups A and B have different dimensions for the thermal insulation and the distance between collector cover and absorber, hence the values for UL and Ce from set-up A an B cannot be directly compared.

The trend of UL for September 9 and 14 in Fig. 7 shows that the heat loss coefficient increases steeply when the flap is opened and converges then to a final value. This is due to the dimensions of the flap opening and slit aperture. At first the dimensions are sufficient to provide sufficient cooling. With increasing AT an asymptotic limit is reached where the geometric and aerodynamic limit is so that the maximum heat loss of the collector through passive ventilation is reached.

For Sept. 14 the initial and the final value for UL are larger than for Sept. 9. This is caused by the enlargement of the slit aperture at the bottom of the collector from 15 cm to 20 cm and the changed flap’s sensitivity settings. Due to the larger slit aperture (bottom) the heat loss is already larger from the beginning (Sept. 14). Further, due to the higher sensitivity of the flap setting the flat opens wider for certain AT, which results in a higher heat loss coefficient.

|

9 |

Sept. 9, 2006 |

9 |

Sept. 14, 2006 |

|

8 |

,»• * |

8 |

• ♦ ♦♦ |

|

7 |

t |

7 |

. / |

|

6 |

* . « . * |

6 |

. * |

|

5 |

5 |

||

|

4 |

4 |

||

|

3 |

3 |

Tilt angle: 60% |

|

|

2 |

Tilt angle: 42% |

2 |

Flap setting: 6 mm |

|

Flap setting: 8 mm |

1 |

Slit aperture (bottom): 20 mm |

|

|

Slit aperture (bottom): 15 mm |

0 |

———— 1———— 1———— 1———— 1———— 1———— 1———— 1———— |

|

= (Tbs |

|

— Ta ) |

|

^T = (Tbs |

|

— Ta ) |

|

0 |

Fig. 7. Heat loss coefficient UL as a function of the temperature difference AT = (Tabs, avg — Ta) with ventilation

flap in operation; measurements for different tilt angles, flap settings and bottom slit apertures [set-up B];

Passive ventilation has been investigated as a method to limit overheating in polymeric collectors during thermal stagnation. Measurements were performed outdoors at two experimental set-ups, which consisted respectively of a ventilated and a non-ventilated (reference) collector.

For set-up A, a maximum temperature reduction up to 30 K between ventilated — and reference collector was measured. Corresponding results were obtained in [1,2] by modelling and in [3] by measurements; for the latter the ventilation was performed on the backside of the absorber.

In the present studies the temperature in the solar collector was reduced from above 145 °C to less than 120 °C. The temperature reduction was obtained with a distance of 28 mm between the absorber surface and the collector cover. The slit aperture openings were varied between 1020 mm. This changed the temperature reduction with 5-10 K, with largest cooling effect for the large slit aperture. The temperature difference between the reference and the ventilated collector increased with increasing tilt angle.

In set-up B, the slit aperture in the bottom of the collector frame was constant while an adjustable, temperature-triggered flap determined the slit aperture in the top. It was shown that the longitudinal thermal expansion of the polymeric absorber is sufficient to trigger the ventilation flap in the top and initiate the ventilation. The ventilation flap concept seems to work effectively.

A simple method to determine the heat capacity of glazed polymeric solar collectors by means of stagnation temperature measurements has been investigated. The advantage of the method is that the collector efficiency can be obtained from the collector’s stagnation temperature and solar irradiation measurements only. The disadvantage is that additional information about optical and heat removal properties is required. This method is a valuable tool to determine the heat loss coefficient and the heat capacity (and hence the collector efficiency) of building integrated, polymeric collectors.

[1] M. Kearney, J. Davidson, S. Mantell, Polymeric absorbers for flat plate collectors: Can venting provide adequate overheat protection?, Journal of Solar Energy Engineering, ASME, August 2005.

[2] J. P. Roberts, M. J. Brandemuehl, J. D. Burch, K. M. Gawlik, Overheat protection for passive solar water heating systems using natural convection loops. Madison: Proc. of ASES Annual Conference Solar 2000, Wisconsin, 2000.

[3] S. J. Harrison, Q. Lin, L. C.S. Mesquita, Integral stagnation temperature control for solar collectors. SESCI 2004 Conference University of Waterloo, Ontario, Canada, 2004.

[4] Wavin B. V. Solar collector with plastic tubes for transfer medium — and heat-exchangeable overheat protector to open housing wall for convection cooling. Patent, Publication number: NL8105671, Publication date: 1983-07-18.

[5] K. Resch, G. M. Wallner, Thermotropic materials for overheating protection of solar collectors. In Proceedings of the EUROSUN 2008 Conference, October 7-10, 2008, Lisbon, Portugal.

[6] K. Resch, G. M. Wallner, Overheating protection with thermotropic resin systems: Effect of material structure and morphology on light-shielding efficiency. In Proc. of the EUROSUN 2008, Oct. 7-10, 2008, Lisbon, Portugal.

[7] K. Resch, R. Hausner, G. M. Wallner, Modeling of an all-polymeric flat-plate collector with thermotropic overheating protection. In Proceedings of the EUROSUN 2008 Conference, October 7-10, 2008, Lisbon, Portugal.

[8] R. Griessen, M. Slaman. Solar collector overheat protection. Patent number: P6017675NL; Patent/IP status: filed.

[9] R. Hausner, C. Fink, R. Riva, Quantifizierung des Stagnationsverhaltens von thermischen Solarsystemen.

Staffelstein: Tagungsbeitrag 13. Symposium Thermische Solarenergie, 2003.

[10] J. Gjessing, Ventilering som metode for a redusere stagnasjonstemperatur i solfangere. Master thesis at the University of Oslo, November 2006.

[11] N. Rumler. Untersuchung von Kunststoffkollektoren hinsichtlich Uberhitzung im Stillstandsfall. Master thesis at HTWK Leipzig with practical project at University of Oslo, January 2007.

[12] General Electric Company, GE Advanced Materials Plastics, NORYLs Resin EN150SP Data sheet, 2005.

[13] A. Olivares, J. Rekstad, M. Meir, S. Kahlen, G. Wallner. A test procedure for extruded polymeric solar thermal absorbers, Solar Energy Materials & Solar Cells 92(4), 2008, p. 445-452.

[14] S. Kahlen, G. M. Wallner. Degradation behavior of polymeric materials for solar thermal applications, In Proc. 27th PDDG Meeting, Aston University, Birmingham, England, September 2007.

[15] J. A. Duffie, W. A. Beckman (1991). Solar Engineering of Thermal Processes, 2nd ed. Wiley Interscience, New York.

[16] EN 12975:2. Thermal solar systems and components, Solar collectors-Part 2. European Standard EN 12975-2:2003.

[17] M. Kohl. Messung des solaren Absorptionsgrades und des thermischen Emissionsgrades, MeBprotokoll. Fraunhofer Institute for Solar Energy Systems, 27.04.2000.

[18] H. Visser, P. van Staalduinen, B. G.C. van der Ree, H. P. Oversloot, A. J. Koelemij, S. Bijma. Assessment and recommendations for application of the SolarNOR energy roof/facade, Second draft. Report number 95-BBI-R1217, Project no: 526.6.3582. TNO, The Netherlands, 1996.

[19] J. Gjessing, J. Rekstad, M. Meir. A method to determine the u-value and the heat capacity of glazed polymeric solar collectors. Manuscript prepared for submission for Buildings and Energy; status: September

Beside the collection efficiency, other optical characteristics have been monitored to evidence how much they are affected by geometrical deformations of the solar trough profile. The second study combines the consequences of mirror deformations with misalignment and tracking errors.

The crucial optical features to be considered in examining alignment and sun tracking are angular misalignment and acceptance angle of the solar trough collector.

The angular misalignment is simulated tilting the solar trough, with a rigid rotation of parabolic mirror and absorber around the axis of parabolic vertexes. Analogously to the previous study, the parameters defining the solar trough layout are: f=780mm, D=50mm, G=70mm, T=2mm. Figures 4-5 show parabolic mirror profile and circular absorber section, whose centre is located in the parabola focus. Figure 5 illustrates the rigid rotation of parabolic mirror and absorber, for a tilt angle of 1.1°. For rotation in the right direction, the collected light impinges on the left portion of the metal pipe, instead of being symmetrically distributed as shown in Fig. 4, corresponding to tilt angle 0°.

|

Fig. 4. Parabolic trough without tilt. Fig. 5. Parabolic trough with tilt of 1.1°. |

|

Fig. 6. Effect of angular misalignment. |

The effect of collector angular misalignment is assessed considering the collection efficiency E (ratio between focused and entering light). The behaviour of collection efficiency is reported in Fig. 6, for misalignment angles in the range (-1.5°; 1.5°). The absorber centre is located in the focal point of parabolic mirror. The curve evidences that the collection efficiency almost maintains its maximum value between -1.1° and 1.1° for the solar trough under test. This limit angle represents the acceptance angle of the solar trough collector: significant energy losses will appear for angular misalignments exceeding the acceptance angle 1.1° (in Fig. 5).

Since the consequences of angular misalignment depend on the geometrical parameters of solar collector, this second study proceeds combining the angular misalignment effects with the mirror deformations effects.

In general polymers are incompatible with one another as a result of low entropy of mixing and the positive energy of mixing between polymers. Exceptions to this rule are for example metastable, partly miscible systems which exhibit a Lower Critical Solution Temperature (LCST). At low temperatures the polymers interact via salt formation, hydrogen bonding, complex formation, п-electron interaction or dipolar interaction. The miscibility decreases with increasing temperature associated with the formation of domains. As a result the layer turns opaque. Thermotropic polymer blends are poured mostly as films from an organic solvent on a glass or a polymer substrate [2,3,20].

Typical polymer blends developed for overheating protection purposes are based on acrylate polymers mixed with either chlorinated rubber or polystyrene [23]. Other systems are styrene- hydroxyethylmethacrylate based with polypropyleneoxide as a second polymer [24,25].

In general thermotropic polymer blends are environmental-friendly and can be produced in a large area at low costs. As to their switching range thermotropic polymer blends are well suited for solar thermal applications. Thermotropic polymer blends undergo a transition from a highly transmitting state to a highly reflecting state (change in solar transmittance by 52%) at temperatures variable between 30 and 130°C [20,23,24]. However, these material types show a switching within a broad temperature range along with high reversibility within a broad time-frame (up to 15 hours) [26]. Furthermore the materials are susceptible to humidity and UV radiation and exhibit problems with long-term stability [27]. To apply thermotropic polymer blends as overheating protection devices of solar collectors further developments should focus on the adjustment of switching temperatures between 55°C and 80°C and on the improvement of the long term stability and switching performance.

Kollektorfabrik has laid the foundations to produce a solar air collector which meets the technical requirements of efficient solar energy usage. This collector complies also with the needs of installers and craftsmen, customers and investors.

The field test in private households with heat exchangers for domestic hot water production and direct use of air for heating was started in September 2008. Larger collector fields for solar heat for industrial processes are currently under negotiations.

|

Fig 2. A demonstration field of an early prototype stage with five modules. |

Characteristics of the air collector of Kollektorfabrik

• In comparison with unglazed or flat-plate collectors a higher temperature level can be supplied for processes by means of vacuum tubes.

• For space heating applications in private households a further system with heat exchanger and fan is available.

• Optimized area ratio between absorber and header surface.

• Different geometries and sizes are possible.

• Different designs are possible, for e. g. header with different colors and different sizes.

• Safe and fast installation without the need for long instructions.

• Lightweight construction (ca. 20 kg/m2) for loadsensitive sub-structures.

• The solar thermal air collector of the Kollektorfabrik has a total area of ca. 9.2 m2. A typical household would use about two or three air collector modules for domestic hot water production and space heating.

• A heating system perfectly fitted around roof windows and a smooth adaptation of the dormers of a roof can be realized by means of vacuum tube of different lengths.

Sustainability

• The usage of decentralized renewable energy represents a major contribution to secure environment, supply independency and to deal with depleting resources. The use of solar thermal heat is a cooperatively easy and effective way to do so. With the introduced collector, high solar fractions are easy to realize thus achieving an important impact on the energy supply chain.

• From an economic point of view, a reasonable investment is strictly connected to its life time, its total costs and total benefits of ownership. By integrating the solar air collector into a suitable application not only the energy supply is secured in an ecologically way. The economic investment also achieves sustained success.

Reliability

• High solar fraction of typical solar thermal systems comes often along with a partial energy overrun in summer. Ideal, easy to run applications need the most heat when the radiation is at the maximum (e. g. solar cooling). If this is not the case, additional components are — depending on the size of the collector field — absolutely necessary to deal with stagnation problematics in summer. These would be e. g. space consuming big storages, advanced intelligent controller with nightcooling (heat rejection), redundant pumps, electricity backup unit, rating rules for expansion vessels, special connecting schemes and advanced solar fluids.

Whereas the collector developed by Kollektorfabrik is intrinsically safe. If the system, a sensor or a actuator fails, even if the system was not installed properly, the collector does not deteriorate during stagnation condition neither does it damage any other part of the system.

• Therefor, no particular measures are necessary to guarantee safety during weekend, lunchtime, process interception or vacations of companies, schools, public buildings etc. The solar air system can resume after a break and even start from full stagnation and inner absorber temperatures up to 250°C without the risk of thermal shocks.

• The collector of Kollektorfabrik meets the requirements based on the test conditions of the European Norm for collector testing (EN 12975-2).

Cost effectiveness

• Kollektorfabrik has developed a long-lasting intrinsically safe collector with the focus on maximum energy output at high temperatures (30°C — 130°C) in the cold and hot seasons.

• Some details were implemented that enable an easy and fast mounting of the collector, thus reducing costs connected to installation.

• Special attention was given to make the collector lightweight so it can be moved without a crane. A Team of two persons can easily transport the collector to a roof e. g. through a roof light and install it. This lowers the costs of installation.

• Kollektorfabrik initiated the development of a fan with extremely low power consumption which could even be driven as standalone system in combination with pv-cells.

• With the scientific assistance of the Fraunhofer Institute for Solar Energy Systems the aerodynamics were optimized through CFD-Simulations and proofed on the test facilities of the Fraunhofer ISE. This way, a maximum benefit can be achieved at a minimum auxiliary power.

• There are several possibilities to store the heat from hot air. It could be transferred into water and stored in a water tank or it could be stored directly and cost effective in the thermal mass of walls and floors or lossless in sorption materials.

Different possibilities to influence the technical and optical appearance like color shadings, different length of the tubes, different sizes and different angles of the tubes make the solar air collector field of Kollektorfabrik unique. It becomes a part of the house, the building or the application the collector is made for. This grades up the application itself, modernizes the building and makes the object of the heat supply more valuable.

Tests shall be performed with system components installed in accordance with the manufacturer’s installation instructions. The collector shall be mounted in a fixed position facing the equator within a range of ±10 and located in such a manner that a shadow should not be cast onto the collector at any time during the test period.

|

The schematic representation of experimental apparatus for test procedure system is shown in Fig. 1. It is an open circle loop that contains solar collector, storage tank, valves, and measurement sensors, such as flow meter, radiometer, temperature sensors etc. There are three temperature sensors used in storage tank for two reasons: (a) to obtain the stratification profile in the storage tank along the test and (b) to determine when the homogenized temperature in the storage tank is reached (see Fig. 1.).

Fig.1. Experimental apparatus for the performance test

The responsibility of the loop is also to recirculate the fluid, using a small pump to allow the quick circulation of the water from the storage tank to the collector. The loop has also an air vent, whose operation can drain off the air to make the flow rate at a stable level. The whole loop shall be insulated to ensure a heat loss rate of less than 0.2 W/K and protected with reflective weatherproof coating, so that calculated temperature loss or gain along the homogenize procedure does not exceed 0.2 K under test conditions.

Additionally the ambient temperature is measured using a shaded thermal resistance 1 m above the ground approximately and not closer than 1.5 m to the collector and system, the inlet and outlet water storage tank temperatures are measured with thermal resistance, global solar irradiance sensors are also integrated on the collector plane and an anemometer is also installed in order to measure the wind direction and speed.