Как выбрать гостиницу для кошек

14 декабря, 2021

Validated models are used for the parameter analyses [4]. The validation was carried out in 2007 with measurement data from the four different evacuated tubular solar collectors tested in a test facility at the Technical University of Denmark. In Table 1 the values used and determined in the validation process are shown.

Table 1. Parameters for the four solar collectors.

|

Parameter |

Seido 5-8 |

Seido 1-8 |

Seido 10-20 Curved |

Seido 10-20 Flat |

|

Collector type |

||||

|

Total gross area of the collectors [m2] |

2.07 |

2.07 |

3.53 |

3.53 |

|

Transparent area of the collectors [m2] |

1.38 |

1.38 |

2.25 |

2.25 |

|

Number of tubes [-] |

8 |

8 |

20 |

20 |

|

Glass tube radius [m] |

0.05 |

0.05 |

0.035 |

0.035 |

|

Tube centre distance [m] |

0.120 |

0.120 |

0.09026 |

0.09026 |

|

Collector panel tilt [°] |

67 |

67 |

67 |

67 |

|

Collector azimuth [°] |

0 |

0 |

0 |

0 |

|

Incidence angle modifier for the diffuse radiation [-] |

0.9 |

0.9 |

0.9 |

0.9 |

|

Effective transmittance — absorptance product, [-] |

0.83 |

0.83 |

0.83 |

0.83 |

|

Number of discretizations for the absorber [-] |

41 |

41 |

33 |

15 |

|

Angle dependence of tau-alpha product based on tangent equation [-] |

3.8 |

3.8 |

3.8 |

3.8 |

|

Heat capacity of the fluid in the manifold tube [kJ/kgK] |

3.8 |

3.8 |

3.8 |

3.8 |

|

Heat pipe length [m] |

1.73 |

1.73 |

1.61 |

1.61 |

|

Absorber radius [m] / Absorber width [m] |

0.041 |

0.085 |

0.027 |

0.056 |

|

Angle of strip [°] |

164 |

— |

164 |

— |

|

Thickness of strip [mm] |

0.47 |

0.47 |

0.60 |

0.60 |

|

Thermal conductivity of strip [W/mK] |

238 |

238 |

238 |

238 |

|

Density of strip [kg/m3] |

2700 |

2700 |

2700 |

2700 |

|

Heat capacity of strip [kJ/kgK] |

0.896 |

0.896 |

0.896 |

0.896 |

|

Lowest evaporation temperature [°C] |

15 |

15 |

15 |

15 |

|

Manifold heat exchange capacity rate [W/K] |

10 |

10 |

10 |

10 |

|

Mass of the fluid inside the heat pipe [kg] |

0.0038 |

0.0038 |

0.0038 |

0.0038 |

|

Effective heat capacity of the collector [kJ/K] |

4.04 |

3.41 |

6.31 |

4.94 |

For the validation of the developed mathematical model, the results of the DST tests of one thermosiphon system product line are used. Systems of this product line with different collector area and store volume were tested according to the DST method at the three laboratories CSTB, INETI and ITW. The results obtained from these tests were compared with the results that are obtained with the mathematical model. In Table 4, the test results based on the DST-test for the location of Athens and a hot water demand of 200 l/d are listed in the column fsol, DST.

In the same table, the results obtained with the mathematical model are depicted. The parameters of the different systems that have been entered in the program as “system tested” are defined in the line: “Input value fsol, DsT“. With the extrapolation tool DHWScale, the values fsol, calc are calculated for the remaining systems of the product line. In addition, the discrepancy between the calculated values of the solar fraction and the solar fractions obtained by the DST-method (Afsol = fSOl, DST — fsOi, caic ) and the relative error (srel) between both values is displayed. The relative error between the results obtained for fsol from the DST test and the calculation procedure is calculated by the following equation (5),

sol, DST

For the validation, three trials have been performed:

In the first trial (Trial 1) a thermosiphon system with Ac = 3.48 m2 and Vsto = 0.18 m3 (System no. 1) has been tested with the DST-method and a solar fraction of fsol, DST = 0.74 has been obtained. These values are now entered into the DHWScale program to extrapolate the results to systems of the same product line but different in size. For the systems 2 to 7 of the same product line the values of fsol can be found in the column “Trial 1, fsol, calc1”.

In a second trial it was assumed that a thermosiphon system with Ac = 3.96 m2 and Vst0 = 0.15 m3 (System no. 4) has been tested with the DST-method and a solar fraction of fsolDst = 0.70 has been obtained. Again, these values are entered in the DHWScale program. The results obtained for the other systems of the product line by means of extrapolation are listed in the column “Trial 2, fsol, calc1”.

For the third trial it is assumed that two thermosiphon systems (system 3 and system 7) have been tested with a DST-test. The parameters of both systems have been entered into the program as input data in order to obtain the solar fractions for the 5 remaining systems of the product line.

|

Table 4. Comparison of DST-results and the results from the mathematical model

|

As can be seen from Table 4, also for the system tested with DST, there is a discrepancy between the solar fraction obtained with the DST-method and the solar fraction obtained with the mathematical model. This results from the fact that there is no equation fsol = f (A, Vto) which exactly matches the default value from the DST-method.

The maximum relative error for Trial 1 is 5.9 % , 10.6 % for the second trial and 5.6 % for the third trial. The mean error, defined with

є1 +є2 +… + Є8

8

is 2.25 % (Trial 1), 5.9 % (Trial 2) and 3.0 % (Trial3). For the other hot water demands of 110 l/d and 300 l/d comparable results are obtained.

An extrapolation procedure including a mathematical model has been developed which can be used for determination of the solar fraction of systems which are part of a product line. By means of an extrapolation procedure, input values for only one or a few systems have to be determined by physical testing. The developed procedure has been implemented in an EXCEL based software tool named DHWScale.

As the model is based on second order polynomials, results can be obtained within seconds. The mathematical model has the advantage that only a few system tests are necessary to determine the solar fraction for a whole product line. This approach can offer the possibility to reduce the time and cost necessary to obtain Solar Keymark certification of factory made solar domestic hot water systems. The validation of the program with one thermosiphon product line tested by DST showed promising results. Depending on the desired accuracy already one system test may be sufficient (relative error of about 11 %). If two system tests are performed the relative error drops to 6 %. However, up to-date only DST-results for one product line are available. For a more profound assessment of the developed procedure more product lines have to be tested with the DST-method.

In principle it is possible to extend the DHWScale program towards other system designs such as forced circulated DHW systems with or without integrated auxiliary heating. First experiences have been gained with forced circulated DHW systems but a validation is necessary before any reliable statement about the accuracy of the results can be made. It is also expected that for other system types further parameters have to be taken into account such as the influence of the auxiliary heated volume. This will envoke a huge number of additional TRNSYS simulations.

The DHWscale program is a first approach for the determination of system test results by means of an extrapolation procedure. In principle the methodology of this approach can be extended to additional parameters (e. g. locations, loads) and other system concepts.

/1/ H. Druck, S. Fischer, H. Muller-Steinhagen,

Solar Keymark Testing of Solar Thermal Products; Proceedings of ISES 2007 Solar World Congress, September 18 to 21, 2007, Beijing, China, ISBN 978-7-302-16146-2, Tsinghua University Press, Beijing and Springer-Verlag GmbH Berlin Heidelberg, CD: ISBN 978-7-89486-623-3

/2/ DIN EN 12976, „Thermal solar systems and components — Factory made systems — Part 2: Test methods”

/3/ ISO 9459-5:1995, “Solar Heating — Domestic water heating systems — Part 2: Outdoor test methods for system performance characterisation and yearly performance prediction of solar system.

/4/ Research and experimental Validation on the DST Performance test Method for solar Domestic Water Heaters, Final Report, Contract No. SMT4-CT96-2067

At the Fraunhofer ISE a testing facility for solar domestic hot water systems (thermosiphon systems, systems with forced circulation, integral collector-storage systems) and heat storages is already in operation since 1997.

Now a new testing facility has been engineered to satisfy the growing demand for the tests on solar domestic hot water systems according EN 12976 [1]. This testing stand provides the possibility to perform tests of four different systems at the same time and independently.

The testing facility and its sensors fulfils very high testing and measuring requirements. The boundary conditions during testing can be handled in a far better way than in the previous test stand. This concerns, for example, the cold water inlet temperature during the tests and the ambient temperature of the storage tank.

The testing facility is designed for tests on complete solar heating systems and heat storages.

In 2000 and 2001 the first edition of the European standards for solar thermal systems and components was issued, and started to replace all related national standards /1/. The three standard series consisted of the following seven parts listed in Table 1.

|

Table 1: Titles of European solar thermal standards as published in 2000 and 2001

|

E. Andersen* and S. Furbo

Department of Civil Engineering, Technical University of Denmark, Brovej, Building 118, DK-2800 Kgs.

Lyngby

* Corresponding Author, 5an@byg. dtu. dk

Abstract

The long time durability of seven different two layer fabric inlet stratification pipes for enhancing thermal stratification in hot water stores is investigated experimentally. Accelerated durability tests are carried out with the inlet stratification pipes both in a domestic hot water tank and in a space heating tank. Heating/cooling cycles are carried out with different operation conditions including different temperature levels and volume flow rates.

The results show that that lime contained in the domestic water is deposited in the fabric pipes in the domestic hot water tank and that this destroys the capability of building up thermal stratification for the fabric inlet stratification pipe. The results also show that although dirt, algae etc. are deposited in the fabric pipes in the space heating tank, the capability of the fabric inlet stratifiers to build up thermal stratification is unchanged for five out of seven fabric pipes within the test period.

Keywords: Hot water tanks, thermal stratification, fabric inlet stratifiers, long time durability of fabric inlet stratifiers

1. Introduction

Previous investigations have shown that thermal stratification in hot water stores can be built up in a very good way with inlet stratification pipes made of two fabric layers [1, 2, 3]. This is true even with volume flow rates through the pipes as high as 10 l/min. Many different fabric styles have been investigated including both stretchable and non-stretchable fabrics but the investigation did not result in one superior fabric being pointed out. On the contrary, several of the tested fabrics show similar good behaviour.

Based on these promising results, accelerated long time durability tests are carried out with two fabric layers inlet stratification pipes made of seven different fabric styles, see Table 2.

|

Table 1. Investigated fabric styles.

|

The long time durability tests consisting of continuous heating/cooling periods of hot water stores with built in inlet stratification pipes have been going on for one year and the fabric pipes have been inside the tanks during this time. Hot water is pumped into the tanks through the inlet stratification pipes during all heating periods. In average each fabric pipe has been in operation in 480 hours. During this period the inlet temperatures have varied in the range 30°C — 70°C. The volume flow rates have varied in the range 2 l/min — 10 l/min. The applied operation conditions correspond to operation of a solar heating system with a solar collector area of 10 m2 with a volume flow rate in the solar collector loop of 0.2 l/min per m2 solar collector area in 2/3 year. Solar heating systems with flat plate solar collectors are typically in operation 1800 hours per year in Denmark.

For each exposed sample a transmission spectrum was measured; in the beginning utilizing a manually operated Zeiss-Spectrometer and since 1995 with computerized Fourier Transform Spectrometers (Bruker, IFS 66), all equipped with integrating spheres. These spectra were used for the calculation of the solar transmittances based on an AM 1.5 solar spectrum (ISO 9845). In order

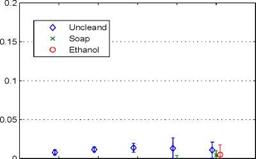

to approve the comparability of the different instruments, measurements performed on unexposed reference plates in the year 1985 were compared with re-measurements of the same samples in 2005. The comparison of 36 measurements resulted in a deviation of only 0.2 ± 0.5 % (relative) confirming the good comparability of these measurements. To investigate the effect of soiling half of each sample was cleaned with mild soap and a soft sponge to be measured separately. Some of the samples were additionally cleaned with ethanol to get a better differentiation of soiling and degradation effects.

An overview of the losses in solar transmittance of the tested materials after 20 years of exposure is given in Fig. 3. The losses reported after 20 years are lower than after 10 years of exposure because of heavy rainfalls in the run-up to the sample collection in 2005, which led to nonnegligible cleaning effects. Multi-skin sheets and sinuous plates are not considered in this study. For these samples additional losses were observed as a consequence of the special form and not as a material property. Detailed analysis of the weathering properties of the different materials are presented as follows.

|

Table 3. Comparison of the losses in transmittance in Davos and Rapperswil after 20 years of exposure. For a better comparability multi-skin-sheets and sinuous plates made of PC and PMMA are not considered.

|

Modern collector glazings are mainly made of low Fe glasses because of their good durability and high transmittance. The influence of a structured surface for reflex reduction (prism-like structure in the dimensions of millimetre fractions) on the soiling property of such glasses was investigated in this study. In Fig. 1 the losses in transmittance of samples with a structured surface are compared to the losses of the samples with a smooth surface. No difference according to their total transmittance losses could be identified between these two groups; the structure did not lead to increased soiling.

Eight samples of iron containing float glass were included in this test. No clear difference in terms of losses in transmittance could be identified between samples with the tin-rich float side or the tin — poor side exposed (i. e. oriented to the ambient). For both glass types losses in transmittance in the range of 10 % (relative) were observed in Rapperswil after 20 years of exposure (without cleaning). After ten years of exposure the losses were even higher due to less rainfall in the time before sample collection. At the rural site of Davos only small losses in the range of some percent were observed over the whole test period. As shown in Figure 2 on the example of float glass, the cleaning with mild soap lowered the losses to about half of the initial value. A further amelioration was achieved by the cleaning with ethanol. A slight increase in transmission that was observed around the wavelength of 1 pm was probably caused by a photo induced oxidation of Fe2+ impurities [2].

For all flat PMMA samples good weathering properties were observed; the losses in transmittance were in the range of the losses of glass or even slightly better. Especially the cleaning with ethanol had a stronger effect compared to glass; see Fig. 2 and Fig 3. For the 20 year old samples cleaned with ethanol, close to no significant losses in transmittance were measured. On the other hand a loss in transmittance in the range of two percent (relative to the initial transmittance) was observed

for the 20 year old glass samples from Rapperswil.

|

|||

|

|||

|

|||

|

|||

|

|

||

Fig. 3. Soiling and cleanability of PMMA; mean value and standard deviation of the six tested flat PMMA

types.

In the unexposed state the UV-absorbing effect of some protective additives was observed for all PMMA types but with different efficiencies (the full lines in Fig.4). For four of the six types this UV-blocking property remained over the whole 20 years of exposure, similar to the sample declared as ‘strong UV-absorbing’ in Fig. 4. They proved to be suitable for the use as UV-blocking layer to protect other materials. For the other two PMMA-types a continuous gain in transmittance in the UV-range was observed over the duration of exposure. This deterioration of the UV — blocking mechanism did not cause any other visible material degradation. For these samples even a slight gain in solar transmittance was observed due to the gain in the UV-region. But it is known from artificial weathering of PMMA that some photo-degradation in the form of chain braking exists and affects the mechanical properties [3].

|

|

|

|

Fig. 4. Changes in UV-blocking for different PMMA samples.

The two tested PMMA sinuous plates with glass fibre reinforcement suffered from large losses in transmittance caused by fissures in the polymer matrix similar to the UP samples (see 4.5. UP).

2.2. PC

For all tested PC-types material degradation was observed including yellowing, surface roughening and even biological infestation for some samples exposed in Rapperswil. PC degradation is caused by photo-Fries and photo-oxidation processes caused by UV-irradiation. These reactions are influenced by additional parameters as humidity and temperature resulting in a roughened layer of degraded material of variable thickness at the sample surface [4]. In this case of open exposure a macroscopic removal of material from the surface was observed and quantified. After 20 years the

loss in plate thickness was for all PC-types and at both exposure sites in the range 0.1 mm. In Fig.

|

5 the loss in plate thickness as a function of the exposure time is shown for one sample, which was exposed in Davos. This figure shows that the material removal started shortly after three years of exposure, which coincides with a lifetime estimation of three years determined by Ram et al. [5]. The exact loss in transmittance due to material degradation could not be determined as soiling can not be cleaned without irritating the weathered surface. A good estimation can be taken from the total losses in Davos, where for other materials as glass or PMMA the contribution of soiling to the total losses in solar transmittance was small. Despite of a visible yellowing the solar transmittance only decreased by 3.3-7.7 % of which a small part is still caused by soiling. For the tested PC-types the cleaning effect of heavy rain in the period before of the 20 years sample collection was more pronounced than for other materials. An elevated gain in transmittance between 10 and 20 years of exposure is caused by the fact that not only soiling but also peaces of weathered polymer were removed from the surface by rainfall. A regain in transmittance for long exposure times was also observed in artificial weathering tests by Tjandraatmadja et al. [4] who identified photo-bleaching of the yellowed layer to be the cause of this effect. The PC films (thickness 0.375 mm) were mechanically destroyed as a consequence of material degradation.

4.4. Fluoropolymers

All fluoropolymers suffered from unexpected high losses in transmittance. In the case of PVF and FEP these losses were only caused by soiling; by cleaning with ethanol the initial transmittance could be recovered even after 20 years of exposure, see Fig. 6. The losses from soiling were in the range of ten percent or more, even in Davos where comparable losses of glass or PMMA were in the range of only one to two percent. For collectors with FEP or PVF glazing a regular cleaning is important to reduce losses in efficiency caused by soiling. For ETFE the effect of cleaning was small (exception: sample No. 1 from Rapperswil). The losses of these samples are caused by persistent soiling or actual material degradation. In contrary to FEP and PVF, this polymer contains unfluorinated ethylene which could serve as point of attack for degradation mechanisms.

Fig. 6. Overview of the transmittances of all tested fluoropolymer sheets. The values of the ethanol cleaned

20 years old samples are compared to the values of the different soiled samples.

All tested UP samples were reinforced with glass fibres. Similar to the reinforced PMMA plates, these samples suffered from high losses in transmittance. Fissures arise from dilatation differences of the UP matrix and the glass fibres due to high temperature changes or water accumulation [6]. Near the surface the UP matrix broke and the fibres poked out of the surface. This roughened surface lead to increased accumulation of soil. On the samples which were exposed in Rapperswil additional biological infestation was observed after 10 and 20 years of exposure.

|

Table 1 gives an overview over the important currently valid European and International Standards which should ensure the quality of solar thermal collectors and PV-modules articulated in application area, standard and short description of their content. Table 1. European and International standards to ensure the quality of solar thermal collectors and PV-modules.

|

Tests of solar thermal collectors and PV-modules according to the valid standards and regulations by independent laboratories should guarantee the quality standard related to the state of the technology, mainly to ensure the continuous growth in order to make a contribution to the sustainable energy supply. Furthermore such tests should ensure the continuous development and should sharpen up the transparency of the European and International market for the consumer. Essential conditions to reach these aims are the general performance of the mandatory tests of all solar thermal and PV-modules in the run up to the market entrance. Furthermore useful, which means to the respective state of the technology and the environmental conditions well adjusted requirements within the different standards. The necessary permanent amendment of the standards is not always able to fulfill these requirements, because the process of the amendment always takes a long time and furthermore is subjected to totally different conflicts of interests between manufacturers, certifiers and political framing conditions.

Under a closer consideration e. g. of the development of the European standard EN12975-1.2:2006 we will see, that the reliability test to check the impact resistance is, unlikely to older versions, no longer an obligatory test, even though severe hailstorms in Europe in recent years definitely increased. Concerning this matter the amendment of the standard does not reflect the requirements resulting from real environmental conditions. Also the appliance of other EU-Standards which harmonize the building shell e. g. for roof lights, for the quality assurance of solar energy systems, is not simply possible. By the reason of different requirements concerning the functionality, formulations like “the choice of the used materials should take into account the risk of hailstorms” are not transferable. For this account it is also not possible to transfer the results from other studies performed up to now which describe the impact resistance against hailstorms of building. Additionally, today we have to think about the standardisation and adaption of testing procedures for a wider distribution of different technologies in the field of solar energy systems.

Ray tracing analysis for the horizontal fin is shown

in Fig. 10. In Fig. 11 the optical efficiency plot for the horizontal fin ICPC shows an unbalanced

curve skewed to the right. The plot shows that the horizontal fin ICPC has greater energy collection efficiency in the evening than in the morning. As seen in Fig. 10, at an angle of 30 degrees, reflected ray striking the fin are both single and multiple reflections. As shown in Fig. 12, at an angle of 150 degrees, the only rays that are reflected to the fin are single reflection rays.

Fig. 13 shows efficiency effects of three different reflectivities of 1.00, 0.94, and 0.70. Efficiency is reduced for the smaller reflectivity values. The curve also skews more to the right for the smaller values of reflectivity.

Comparisons of different gaps between the absorber fin and the cover glass were analyzed by setting the reflectance to 1.00. As shown in Fig. 14, the efficiency is reduced as the gap between the absorber fin and the glass enclosure increases.

The majority of the domestic water supply projects developed until now is based on very simply Domestic Hot Water (DHW) systems like electrically heated storage cylinder and gas or oil heating boilers. For Civil Engineers project designers the calculations were a quite simple task because they used to select the equipment without specific and demanding criteria. Nowadays, it is necessary to choose well the equipments to minimize its life-cycle cost because a minimum of three types of equipments must function together: the solar collector; the storage tank or cylinder

and the backup equipment (e. g. condensing oil or gas heating boilers). The system operation is also controlled by an automatic electronic unit. Not forgetting other system accessories, like pipes, pumps and valves [7,8]. The passive systems are commonly used on single residential buildings and they are more compact and easily mounted. But in multi residential buildings, there are several different consumers and it is necessary to think the most advantageous system installations option. Design professionals are dealing today with this dilemma because: they have little experience; they do not have much technical information to support their choices and there are not yet many multiresidential buildings with this technology in Portugal to learn with. Aware of this situation, a previous analysis for six system possible options (Table 1, Fig 1.) is presented next.

|

Table 1. Multi-residential buildings solar collector system options.

NOTE: Backup systems on electricity are not stimulated by regulations. |

|

water storage tank

Fig 1. Multi-residential building solar collector system options. |

|

Each of these design options has, in a preliminary perspective, positive and negative points.

Systems 1 and 2 — All equipments are individual — Advantages: self management of the system by each family (they adapt the system to their consumptions needs); minimal problems and conflicts with neighbours; the solar panels could be mounted with different tilt angles for each apartment adapted to their consumptions needs. Disadvantages: great number of water pipes and accessories, more building interior space needed and more heat losses; more home interior space to install equipments; high maintenance expenses for each family; if one home produces solar energy

in excess it is not possible to redistribute it; in seasonal or not occupied spaces there is wasteful production of energy; more complexity on the system mounting. System 3 and 4 — Centralized solar collector — Advantages: less initial investment ; better optimization of the collector area and of the solar south-oriented roof area; optimization of the captured solar energy and a rational distribution for all consumers; management and maintenance in charge of the building condominium administration; the energy of seasonal occupied or not occupied homes can be used by others; each individual consumer must adapt their consumptions needs to a collective system. Disadvantages: more home interior space to install equipments; heat exchanger in inverted system; the householders must pay a service not total adapted to their consumptions needs; some homes can take more profit from the solar collector system then others, it depends of the consumption needs schedule and habits. System 5 and 6 — All equipments are sheared by all householders — Advantages: less pipes and accessories; more reduced initial investment; no individual system maintenance; householders pays a total service of hot water supply; better optimization of the collector area and of the solar south-oriented roof area. Disadvantages: initial part of the system with inverted supply system (water supply starts from the first floors); complex management of the return water of the circuit into the water storage tank; variations on hot water temperatures can occur; lack of preparation of the condominium administrations firms to manage this service; system regulated to a constant level of water temperatures not adapted to consume households schedule with less energy efficient management; requires an adapted collective interior space for a high capacity water storage tank and backup equipments; the building structure must resist to higher loads due to the heavy equipments installed; the building architecture must be prepared for maintenance, repair and substitution of big equipments; reduced preparation of the local authorities to deal with this collective systems (taxes to pay etc); big size systems are more vulnerable to operation problems and damages.

The first two systems require some initial investment and in some cases can lead to collector areas that are not effectively used. The second group of systems seems to have more vantages due to the fact that can result in a better flexibility in the system management, made by both condominium administration and individual consumers. The last systems also have some advantages but represent a more vulnerable operating system.

The result of the comparison of the failure detection methods against the criteria described in §2.4 is presented in table 4.1. The performance matrix shows the performance of the failure detection method based on the different criteria. A few things need to be clarified before interpreting the table. First of all, it is assumed that without automatic failure detection there is a possibility for checking data with a manual analysis. This can be effective but is costly (dependent on the level of the analysis). This could be (and is partially) applied for all methods. Therefore, the criterion is limited to automatic failure detection. Because a lot of information is qualitative, it is hard to determine how much a method will cost in future application when it is still in the R&D phase. Also the effectiveness of a method may increase based on practical experience. Furthermore, the (literature) publications in general do not provide a very accurate description of effectiveness and accuracy of the method.

|

Table 4.1 Performance matrix

? = unclear |

1 IOC: only hardware

2 costs for measurement equipment, including one year monitoring

3 Costs per month for 20 year monitoring and at least 30 monitoring systems sold. The main costs are

expected for maintenance and improvement of software (between € 15 and 50 per month) [11].

4 var = variable, sl = solar loop, — aux = whole system besides auxiliary heating system, bs = buffer

discharging loop (optional for IOC)

The IOC is the first method which could result into the implementation of a monitoring and failure detection method into general use of larger solar thermal systems. It has been tested and is commercially available against a reasonable price, but it does not apply to the whole solar system. Manual monitoring, though more costly, is much easier adapted to extensive variation in hydraulics and systems. The method developed at Kassel University is still in development, but could also provide an automatic monitoring solution for large systems. It includes more sensors and a larger part of the system than the IOC approach, and can therefore also analyse individual components. For very small systems the approach followed in FUKS detects several failures at reasonable additional costs.

However, so far none of the above described approaches takes the auxiliary heating system into account, which is also an important source of errors.