Как выбрать гостиницу для кошек

14 декабря, 2021

The implementation program strategy in a jail includes the following activities:

• 600 hours training course on solar thermal addressed to prisoners for the achievement of a

professional qualification accredited by local public authorities,

• a preliminary energy audit of the site,

• a study on the feasibility of the solar thermal plant,

• the adaptation of the standard call for tenders to local peculiarities and needs,

• the evaluation of the projects submitted by the solar companies,

• the involvement of the prisoners in the installation of the plant,

• the monitoring of the energy performances of the system, as required by the Guaranteed Solar

Results (GSR) contract,

• the maintenance of the plant carried out by the prisoners, in cooperation with the technical staff of the

jails.

For a better management of the plants it is expected to install a System Integrated Hardware in order to record the parameters for a real time diagnosis and for proper maintenance.

The system should allow to store the solar systems data and offer the possibility for the institutions involved to carry out the constant monitoring of the plants operating all over Italy.

Battery Park City is located on a reclaimed section of the lower west side of Manhattan. Part of the fill comes from the excavation of the original World Trade Center development. While geographically part of Manhattan, Battery Park City is controlled by New York State’s Battery Park City Authority (BPCA). The Authority has adopted Green Guidelines for the development of all buildings built in Battery Park City. These guidelines require each new building to supply 5% of the base building electrical load through renewable energy generated on site by BIPV systems as well as requiring a multitude of sustainable building practices.

3. Projects

The first project finished under the BPCA Green Guidelines was Site 18A; The Solaire. This project incorporates 4 BIPV systems, a 11 kWp BIPV faqade system, a 650 Wp glass/glass laminate canopy system and a 6.5 kWp south wall and 16.5 kWp west wall weather screen at the top of the building. The building’s developer, The Albanese Organization, used all available funds including NSYERDA funding from the PV on Buildings program Program Opportunity Notice (PON) 449-99 and the New York State Green Building Tax Credit as well as all available Federal Income Tax credits and Accelerated Depreciation. The Solaire is a United States Green Building Council (USGBC) — Leadership in Energy and Environmental Design (LEED®) certified building achieving Gold status.

The system design was inherited by altPOWER with trade claims thoroughly considered. The project owner, construction manager and architect expected and allowed for the following: installation of the custom non-listed BIPV 11 kWp faqade system using a pre-glazed cassette system installed by

Ornamental Ironworkers and later wired up by Electricians. This was a smooth and efficient installation with no trade discussions during construction. The 650 Wp entrance canopy was installed by a composite crew of Ornamental Ironworkers and Glaziers and later wired by Electricians, custom non-listed BIPV modules were used and no trade arguments occurred and overall the rather complicated system went in as expected. The Bulkhead West and South systems at the top of the building utilized standard UL listed PV modules that were tested to survive the high winds expected at the top of the building.

The modules were mounted to the wall using a custom ornamental aluminum mounting system.

These two systems were installed by Electricians, as was expected and planned in a trade agreement. However, this installation was troubled by sloppy work resulting in several PV modules breaking, an extremely slow installation and as a result a high expense.

The team identified the pros and cons of the various system installations and planned better for the next two buildings. The same team would have the fortunate opportunity to work together again on two subsequent projects: The Verdesian and the Visionaire.

|

Fig. 1 Schematic drawing of the room heated for the case studied |

The following assumptions are used in the mathematical modelling: (1) because the temperature changes along the embedded pipe is very minor; the heat transfer of the system is simplified to a two-dimensional steady-state heat transfer. In this regard, the outside surface temperature of the embedded pipe can be considered as uniform; (2) good contact exists between each layer, so thermal contact resistance is neglected; (3) the physical properties of construction materials do not change with temperature.

Before explaining simulation procedure, some general terms are detailed:

• Meteorological data from a weather station located in Madrid were used.

• The simulation period is from November 2005 to April 2006.

• The DX-SAHP system is assumed to operate 24 hours per day.

• A time step of 3600 seconds was selected for the calculations.

Numerical simulation of the system consists of the stages showed in Figure 3:

|

1st International Congress on Heating, Cooling, and Buildings " ‘ 7th to 10th October, Lisbon — Portugal *

Fig. 3. Diagram flow of simulation model Energy balance for the building |

The energy balance carried out in this stage enable us to estimate heat demand of the whole building depending on climatic data and constructive characteristics of the building. A 120 m2 detached house on two floors, designed according to Spanish current building regulations, was selected for this study. Thermal load is calculated as difference between heat losses and heat gains, as ASHRAE Handbook indicates. Heat losses include both loss through exterior surfaces of the building and those due to ventilation. The selected detached house presents an overall heat loss coefficient equal to 335.58 W/K. As heat gains we consider lighting and occupancy loads. Once known heat losses and gains, total heat demand is obtained easily.

Energy balance for the heat pump system

In knowing the heat demand of the building, the energy balance for the heat pump system gives the mass flow rate of refrigerant, the heat that evaporator must collect (Qe in figure 1), the electrical energy consumed by the system and its COP. As a 24 hour a day operation is considered, one can assume that the energy rejected by condenser (Qc) is equal to heat demand of the building (Qt) plus the heat loss from condenser to heat exchangers. According to past experience with heat pump systems, it was assumed that this heat loss represents the 10% of building heat demand. Then, knowing Qc, evaluation of aforementioned parameters is made according to the thermodynamic cycle shown in Figure 2 and considering the following assumptions:

• A hermetic compressor with a mechanical efficiency of 0.90 and an electrical one of 0.95 is supposed.

• Representing average conditions during the heating season, the following condensation temperatures (Tc) were considered: 52 °C in using fan coil heating and 48 °C in underfloor heating.

• The degree of superheat is assumed to be 10 °C and the degree of sub-cooling 5 °С.

• The evaporation temperature (Te) is -12 °С during the whole heating season. Thus, we ensure the panel collects heat from environment during the whole heating season in Madrid

• The energy consumption of auxiliary equipments (Wp and Wp’ in Figure 1) is the 8% of the total input electric power to the compressor.

• The efficiency reduction of the compressor in operating at low capacity is taken into account by the coefficient ф, which is calculated as a function of its nominal power (Wcnom) and the instantaneous one (Wc) as indicated in Figure 4.

1 -0.8 Ф

1 -0.8 Ф

0.6 -0.4 -0 0.2 0.4 0.6 0.8 1

r=Wc/Wcnom

Fig. 4. Low capacity operation coefficient Energy balance for an individual collector

|

Thermodynamic solar panels may be installed in many different ways, but one of the most typical is that one shown in Figure 5. Although this is the configuration studied in present work, other configurations can be also simulated by correcting some initial assumptions in the proposed model.

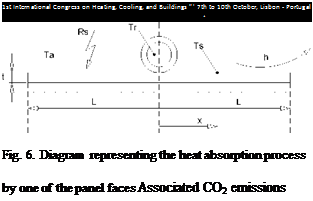

This thermodynamic solar collector absorbs heat from both its two faces. The exposed face receives energy from both solar radiation and environment, while the non-exposed one is supposed not to receive solar radiation. Thereby, the heat transfer occurred on the exposed face is due to radiation and convection; on the other face, convention is the only heat transfer process that takes place. As evaporation temperature is -12 °C a thin ice layer is formed over panel surfaces, making more difficult the heat transfer process. The total heat collected by the panel is obtained by making an energy balance for each face separately. This energy balance was derived from diagram shown in Figure 6, where Rs represents the net solar radiation, Ta is the ambient temperature, t is the thickness of aluminium plate (1.5 mm), Tr is the refrigerant temperature inside the collector tube,

Ts is the surface temperature at point x, h represents the heat transfer coefficient from ambient to collector and 2L is the distance between two consecutive tubes. Neglecting any frictional pressure drop in the collector, the refrigerant temperature inside the collector tube remains constant at the saturation value corresponding to the saturation pressure in the collector. This energy balance permits us to know not only the heat gained by the panel, but also its surface temperature.

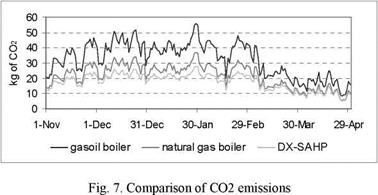

The number of panels needed to cover the total heat demand is obtained by comparing the energy absorbed by an individual collector and the energy demanded in the evaporator. Then, an estimation of CO2 emissions associated to energy consumed by DX-SAHP is made. Next, these emissions are compared with those ones corresponding to natural gas and gasoil heating systems. It was assumed the seasonal performance of natural gas heating system is 0.85 and that one of gasoil system 0.81 [4]. The following ratios of carbon dioxide emissions were considered: 0.358 kg per kWh of electrical energy [1], 0.203 kg per kWh of natural gas and 0.266 kg per kWh of gasoil [4].

2. Results

|

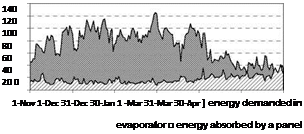

As above mentioned, the comparison of energy demanded in evaporator with energy absorbed by an individual collector gives the number of panels needed to install. Figure 7 shows this comparison, made for a fan coil installation using R134a. As showed in Table 1, seasonal results for the other studied configurations are not too different.

Fig. 7. Comparison of energy demanded and collected in evaporator

|

Table 1. Energy balance for evaporator during heating season

|

One should note that installing the number of panels given in Table 1, the whole seasonal heat demand is provided by the DX-SAHP system. However, when installing 8 panels 95% of seasonal heat demand will be covered in any case. The electrical energy consumed by the different configurations of DX-SAHP in order to cover the whole heat demand is given in Table 2, where the results of seasonal COP are also shown. It is clearly seen that energy consumption is lower when using underfloor heating systems. This is because, in operating with fan-coil, condensation temperature is higher and therefore compressor needs more input energy. Likewise, it should be noted that energy consumption decreases when using R134a as refrigerant.

|

Table 2. Energy consumed by DX-SAHP and seasonal COP

|

|

Finally, Figure 8 shows the comparison of CO2 emissions associated to DX-SAHP using fan-coil and R134a with aforementioned conventional heating systems. The results corresponding to other configurations are indicated in table 3.

|

Table 3. CO2 emissions associated to different heating systems during heating season

|

It is clearly seen that any configuration of DX-SAHP can be an available solution to reduce CO2 emissions associated to building heating. DX-SAHP operating with underfloor heating and R134a

is the most efficient system. Thus, it is able to save roughly 55% of CO2 emissions with regard to conventional gasoil system and 38% with regard to atmospheric natural gas one. Using DX-SAHP with fan coil and R407C, CO2 emissions are 16% higher than using underfloor heating and R134a.

3. Conclusions

A new simulation model was developed to study DX-SAHP in space heating applications. After applying this model to four configurations of DX-SAHP, it is concluded that any of them is an available solution to save energy and reduce CO2 emissions when comparing with conventional heating systems. Likewise, the simulation carried out indicates that installations using underfloor heating and working with R134a as refrigerant are more efficient. On the other hand, simulation results for Madrid indicate that an individual panel exposed to solar radiation may absorb roughly 15 kWh per day. Furthermore, the predicted results for this region indicate that installing eight panels it could be covered 95 % of seasonal heat demand corresponding to a typical detached house.

References

[1] ADENA (2006). Observatorio de la Electricidad

[2] ASHRAE Handboodk. Fundamentals (2005). SI Edition, Atlanta.

[3] F. B. Gorozabel Chata, S. K. Chatuverdi, A. Almogbel. Energy Conversion & Management, 46 (2005), 2614-2624.

[4] F. J. Rey, E. Velasco (2006). Eficiencia Energetica en Edificios. Certification y Auditorias Energeticas. Ed. Thomson, Madrid

[5] H. Hulin, Ge Xinshi, Su Yuehong. International Journal of Energy Research, 23 (1999), 1-6.

[6] K. Kaygusuz. Renewable Energy, 21 (2000), 79-102.

[7] Lu Aye, W. W.S. Charters, C. Chaichana. Solar Energy, 73 (2002), 169-175.

[8] M. N.A. Hawlader, S. K. Chou, M. Z. Ullah. Applied Thermal Engineering, 21 (2001), 1049-1065.

[9] R. Yumrutas, O. Kaska. International Journal of Energy Research, 28 (2004), 163-175.

[10] V. Badescu. Energy and Buildings, 34 (2000), 715-726.

[11] Y. W. Li, R. Z. Wang, J. Y. Wu, Y. X. Xu. Energy, 32 (2007), 1361-1374.

R. N. Farrugia1, C. Yousif1* and M. Villameriel Tejedor2

1 Institute for Energy Technology, University of Malta, Triq il-Barrakki, Marsaxlokk, MXK 1531, Malta 2 E. T.S. Ingenieros Industriales, Universidad de Valladolid, Paseo del Cauce, s/n 47005 Valladolid, Spain.

Corresponding Author, charles. yousif@um. edu. mt

This paper describes the outcome of an energy audit that was carried out in a Maltese residence. Monitoring included all major electric appliances, artificial lighting, solar water heating, and indoor micro-climate conditions. Results showed that almost 40% of the electricity bill was attributed to the back-up heating element within the solar water heating system. Furthermore, a freezer and a fridge-freezer were found to operate continuously without stopping and were responsible for about 20% of the electricity bill. Appliances left in stand-by mode accounted for 10% of the bill. Only 13% of the light fixtures were energy efficient bulbs. Conclusions were that energy use at home was not only dependent on the efficiency of the appliances, but also on the lifestyle of their users, on their background knowledge of energy saving and on the level of their environmental awareness.

Keywords: solar water heating, energy audit, domestic, appliances.

1. Introduction

During the past 15 years, electricity consumption in Malta has been on the increase in spite of higher fuel prices, with maximum summer demand exceeding that of winter as of the year 2001 [1] . Moreover the gap between summer and winter electricity consumption is on the increase. Figure 1 shows electricity generation for four different years, where it is clear that the increase in electricity demand is also across all months and in all years and not for the summer period alone. Since 2001, the domestic sector has become the major consumer of electricity with a share of 36% (Year 2006), followed by the commercial sector at 32% and the industrial sector at 30%. The remaining 2% is attributed to street lighting [2] . Hence, it becomes increasingly important to explore ways and means of improving end-use energy efficiency in homes; bearing in mind the fact that this sector is also a major contributor to peak loads.

The home identified in this case study was situated in the locality of Swieqi, which may be described as an urban area with a high density of upmarket buildings. This project was initiated after the homeowner showed an interest to invest in renewable energy (RE) systems. Initial investigations identified high energy consumption rates — a situation that required redressing prior to the installation of any RE technologies. The dwelling consisted of a duplex — with a top floor apartment leading up to a penthouse. The apartment followed a fairly open plan design and comprised of a main living area with kitchen, laundry room / pantry, study and bedrooms. The penthouse consisted primarily of a lounge, conservatory, summer kitchen and patios.

D. Chwieduk1*, E. Kossecka1 and P. Murza-Mucha2

1 IPPT PAN Inst. of Fundamental Technological Research PAN, Swietokrzyska 21, 00049 Warsaw; Poland

2 GRAFFITI, ul. Boremlowska 30 A, Warsaw, Poland

* dchwied@ippt. gov. pl

The Polish Academy of Sciences has undertaken an initiative to develop the programme on fostering research and application of renewable energy in the country. The core of the programme is to design and construct the Research Center Jablonna that will consist of the Intelligent Energy Building and complex of laboratories. The architectural concept of the 3 storey IEB building has been developed with regard to active and passive application of

solar energy. The shape of the building assures maximum gains of solar energy per year when it is necessary and shading of the interior of the building when it is required. Calculations of solar energy availability have been performed. Shading elements are included, apart from traditional devices as blinds, and building elements as overhangs, the PV modules are to be applied and natural green environment. All “south” rooms at the first floor are seminar and lecture rooms, the “north” rooms are technical — monitoring rooms. Keywords: Solar energy availability, solar architecture, innovative technologies.

1. Introduction

The Polish Academy of Sciences is the owner of different properties all over the country including estates and lands. One of them is a land of 600 000 m2 located at the north east side of Warsaw at Jablonna region. The Polish Academy of Sciences has undertaken an initiative to develop the programme on promotion the renewable energy application with focus on fostering research on innovative energy technologies. The main part of this programme is to develop project “Research Center Jablonna — Energy conversion and renewable energy” including construction of buildings of the Centre on selected part of the land.

The Division of Eco-Buildings of the Institute of Fundamental Technological Research at Polish Academy of Sciences takes part in the national project “Research Center Jablonna — Energy conversion and renewable energy”. This project is realised by the EkoEnergia Scientific Network that constitutes several institutes of the Polish Academy Sciences, leading national academic and applied research institutions in field of energy. The Institute of Fundamental Technological Research participates in the task “Elaboration of a concept of the Research Center and the base for its construction”. The important aim of this task has been to elaborate the architectural and technical concept of the Energy Center with focus on the Intelligent Eco-Building — IEB (shown in the middle of Fig.1) that is to have a function of the conference — training center and the hotel building as well and will be equipped with BMS — Building Management System and will demonstrate the innovative energy systems supplied by renewable energy and modern energy saving building construction technologies with respect to minimum of embodied energy.

|

Fig. 1. The architectural concept of the Intelligent Eco-Building and laboratory buildings in Jablonna [3]. |

Total land area of the Research Center is 21.400 m2. There will be the IEB building (total area of 2000 m2, in the center of the Fig.1), connected to swimming pool (total area of 1100 m2, left to the IEB building), two laboratory buildings: one of Integrated Techniques of Solar Energy and Energy Storage (at the front left side of the Fig.1, total area about 1000 m2), the other of Microcogeneration and Ecological Boilers technologies (at the back right side of the Fig.1, total area about 900 m2), outdoor renewable energy testing field (between the Intelligent Eco-Building and Solar Laboratory) and Meteorological Station (at the south east part of the land). Just in the neighborhood (to the west) the Center of Innovative Technologies is planned to be constructed with total land area of 28.500 m2.

S. Herkel1*, F. Kagerer1, B. Kaufmann2 and J. Reiss3

1 Fraunhofer ISE, Freiburg, Germany

2 Passivhaus-Institut, Darmstadt, Germany

1 Fraunhofer IBP, Stuttgart, Germany

* Corresponding Author, sebastian. herkel@ise. fraunhofer. de

1. Within the framework of the International Energy Agency’s (IEA) "Solar Heating and Cooling" implementing agreement, the working group "Advanced Housing Renovation with Solar and Conservation" Task 37 was set up with the goal of describing renovation standards that are possible today, looking into and discussing new developments and implementation strategies at an international level. The focus is on joint national and international renovation projects in residential buildings whose energy consumption for heat and cold supply (space heating, hot water, auxiliary systems, and ventilation) was to be reduced by a factor of four below the national standard. Monitoring results show a good agreement of measured energy consumption with the expected reduction of energy consumption by a factor of sometimes more than five. Solar and other renewable based energy supply systems enables a net zero energy approach even in building renovation.

2. Keywords: IEA SHC Task 37, Monitoring, Renovation, Energy supply, CHP

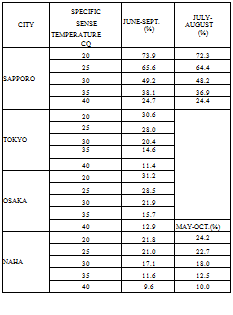

To give one example, Table 1 shows the areal seasonal average natural room temperature of each room in the un-air-conditioning case. From Table 1, for various areas in each room the decrease rate of natural temperature in perspiration mode to non-perspiration becomes bigger as the specific sense temperature lowers. As an example, from Table 1, the maximum temperature decrease at the sense temperature 20 °С becomes 1.1 °C(E/U) in Sapporo, 1.3 °С (E/U, Children) in Tokyo, 1.6 °С (E/U) in Osaka and 1.5 °С (E/U, Children) in Naha. Table 2 shows the decrease rate of sensible heat load (energy-saving rate) due to autonomous perspiration = 1 — (heat load in perspiration mode / heat load in non-perspiration mode). The energy-saving rate by autonomous perspiration also becomes bigger as the sense temperature lowers. It is 72.3 (sense temperature of 20 °C)-24.4%(sense temperature of 40 °С) in Sapporo, 30.6-11.4% in Tokyo, 31.2-12.9% in Osaka, and 24.2-10.0% in Naha, especially bigger in Sapporo.

Table 1 Average natural room temperature (°С) Table 2 Energy saving rate (%) due to autonomous

|

in each perspiration mode for various areas perspiration for various areas

|

ROOM |

MODE |

SAPPORO |

TOKYO |

OSAKA |

NAHA |

|

|

LD |

SPECIFIC SENSE TEMPERATURE ( °С) |

20 °С |

24.0 |

27.2 |

28.3 |

29.9 |

|

25 °С |

24.3 |

27.4 |

28.5 |

30.0 |

||

|

30 °С |

24.5 |

27.7 |

28.7 |

30.2 |

||

|

35 °С |

24.6 |

27.8 |

29.0 |

30.5 |

||

|

40 °С |

24.8 |

27.9 |

29.1 |

30.6 |

||

|

NON PERSPIRE |

24.9 |

28.3 |

29.5 |

31.0 |

||

|

BATHROOM KITCHEN |

SPECIFIC SENSE TEMPERATURE ( °С) |

20 °С |

24.3 |

27.5 |

28.6 |

30.1 |

|

25 °С |

24.5 |

27.7 |

28.8 |

30.2 |

||

|

30 °С |

24.8 |

28.0 |

29.1 |

30.5 |

||

|

35 °С |

24.9 |

28.2 |

29.4 |

30.8 |

||

|

40 °С |

25.1 |

28.3 |

29.5 |

31.0 |

||

|

NON PERSPIRE |

25.3 |

28.7 |

30.1 |

31.5 |

||

|

ENTRANCE UTILITY |

SPECIFIC SENSE TEMPERATURE ( °С) |

20 °С |

23.2 |

26.5 |

27.6 |

29.0 |

|

25 °С |

23.4 |

26.7 |

27.8 |

29.1 |

||

|

30 °С |

23.7 |

27.1 |

28.2 |

29.5 |

||

|

35 °С |

23.9 |

27.3 |

28.5 |

29.8 |

||

|

40 °С |

24.1 |

27.4 |

28.6 |

29.9 |

||

|

NON PERSPIRE |

24.3 |

27.8 |

29.2 |

30.5 |

||

|

MASTER |

SPECIFIC SENSE TEMPERATURE ( °С) |

20 °С |

22.9 |

26.3 |

27.3 |

28.8 |

|

25 °С |

23.1 |

26.5 |

27.6 |

28.9 |

||

|

30 °С |

23.4 |

26.8 |

27.9 |

29.2 |

||

|

35 °С |

23.5 |

27.0 |

28.2 |

29.5 |

||

|

40 °С |

23.7 |

27.1 |

28.3 |

29.6 |

||

|

NON PERSPIRE |

23.9 |

27.5 |

28.8 |

30.2 |

||

|

CHILDREN |

SPECIFIC SENSE TEMPERATURE ( °С) |

20 °С |

23.2 |

26.5 |

27.6 |

29.0 |

|

25 °С |

23.4 |

26.7 |

27.8 |

29.2 |

||

|

30 °С |

23.7 |

27.1 |

28.2 |

29.5 |

||

|

35 °С |

23.8 |

27.3 |

28.4 |

29.8 |

||

|

40 °С |

24.0 |

27.4 |

28.6 |

29.9 |

||

|

NON PERSPIRE |

24.2 |

27.8 |

29.1 |

30.5 |

The average convection heat transfer coefficients are derived from the Nusselt numbers (Nu ). In laminar free convection flows the Nu is obtained through different correlations: in the case of symmetric uniform heat fluxes the correlation of Roshenow with c=1.15 [14] is used, in the case of asymmetric uniform heat fluxes the new correlations obtained in this research (equations 1 and 2.) are used for hot and cold walls. In turbulent free convection flows, in the case of wide channels, the correlation of Churchill [5] is used. In forced convection flows, a distinction between developing and fully developed flows is made. In case of laminar developing flows, the correlations of Bejan [2] and Kays [10] are used. In case of laminar fully developed flows, the Nu are constants. In case of turbulent developing flows, a correlation obtained by Saelens [15] is used. Concerning to the turbulent developed flows, the equations of Kays [10] are also valid.

In the case when the rear glass is formed by multiple glass layers, the equations and correlations obtained for air cavities will be used.

Any coating used on the external surface of a window needs to be a hard coating that can resist the wear this surface is exposed to. For this reason hard oxides or nitrides should be used, and for the low emissivity coating fluorine doped tin oxide was used; a coating readily available on the market. The hydrophilic coating tested with respect to external condensation was a titanium oxide coating which is also already available on the market [9]. It is marketed for its “self cleaning” properties, however, and so far not for its effect on external condensation. Two test windows were prepared which consisted of triple glazed IG units with silver based soft low-e coatings on surfaces 3 and 5. For one of the two windows the outer pane was ordinary uncoated float glass and for the other one the outer pane was a hydrophilic coating on the external surface. This coating does not change the surface emissivity of the external surface and the U-value was identical for both windows and with argon filling the centre of glass U-value was 0.65 W/m2K. Both windows had warm edge spacers, although this had no effect on the formation of condensation in the middle of the window.

The test was conducted during the period September to December 2007, and the condensation was monitored in terms of its occurrence rather than number of hours. No detection equipment was used as was the case for the tests in the test box. A reason for this was the cost together with the fact that the windows were used in an ordinary family house. The condensation rate was thus recorded as “number of times condensation occurred” rather than as “number of hours”. It turned out that the formed condensation could look quite different from one time to another and a subjective division was made between “full” condensation and “moderate” condensation. Full condensation means that the amount was sufficient to completely obstruct the view across the whole window, while moderate condensation means that the condensation was visible, but more like haze or just at the lower part of the window, not covering the whole surface. Although most of the occasions with condensation were detected early morning, there were also some days when condensation was noted in the afternoon or evening, defined as “daytime” condensation. On several occasions during the second half of the tested period it was also noted that the surface temperature was low enough for the condensed water to freeze on the window surfaces. Since the visual appearance of the condensation layers is the important parameter, the occurrence was recorded by pictures taken with an ordinary camera.