Как выбрать гостиницу для кошек

14 декабря, 2021

An experimental study is carried out on a prototype of ORC working with HCFC-123. The scroll expander is originally an oil-free open-drive air scroll compressor, adapted to operate in reverse. The heat source consists in a set of heat exchangers supplied with two hot air flows. The condenser is cooled by water (Figure 5).

|

Fig. 5 Schematic representation of the test bench |

V. Martinez1*, R. Pujol1 and A. Moia1

1 UIB, Phisics Department, Campus UIB, Ctra de Valldemossa km 7.5, 1070122 Palma de Mallorca, Spain

* Corresponding Author, victor. martinez@uib. es

Abstract

The development of a solar thermal collector with fixed reflector and tracking absorber, specially designed for supplying process heat in industrial processes and solar cooling, is described. Initially the project was based on the Fixed Mirror Solar Concentrator (FSMC) concept already developed during the 70’s, but after a detailed optical analysis it was decided to use a similar concept based on parabolic mirrors. With this design a maximum theoretical annual averaged efficiency of about 39% could be reached. In order to reduce the number of the necessary mechanisms, the positioning system consists of a grid of 8 lines of receivers driven by 4 articulated arms. The reflector has been manufactured as a sandwich structure with a high reflectivity aluminium sheet as the reflecting surface. Each collector has a 4.5 x 6 m reflector that consists of 16 pieces of 1 x 1.5 m assembled together by means of 5 laser cut steel profiles. The receiver consists of 32 standard U-pipe Sydney collectors. The first prototype has started operation in July 2008 and the main problem detected has been the breaking of some of the evacuated tubes due to thermal stresses. At the moment a complete evaluation of the system is being carried out.

Keywords: Concentrating collector, process heat, medium temperature, stationary reflector

About 30% of the energy consumption in Europe is attributed to the industrial sector [1]. More than fifty percent of that energy spent corresponds to process heat applications at temperatures up to 250°C [2]. The scientific bases of the technology required to supply solar heat at such temperatures are well established. Nevertheless, this great potential does not result in wide-range use of solar thermal collector systems within the industry.

For low temperature range applications (up to 80°C), the main obstacle is probably the relatively long payback periods of the initial investment, typically longer than 10 years. However, other factors should also be taken into account: limited suitable surfaces available, the lack of experience in the installation and operation of large facilities or processes and machinery not adapted to incorporate solar energy.

In the mid temperature range (up to 250°C) one of the main obstacles to overcome, is the lack of a well developed market for solar collectors that are easily integrable into industrial buildings, competitively priced and which can reliably operate at temperatures above 100°C

To address these needs, a project was engaged to promote the development of a new collector specially designed for process heat applications at up to 160°C. On July 2008 the first prototype of this new development has started operation.

Experiments were divided into two stages, in the first one we used 1 g/l marine salted water (15002000 pS/cm) in the feed hot channel and deionised water as coolant. In the second stage a

concentration of 35 g/l (40-46 mS/cm) was used as feed water and the same deionised water in the cooling channel. In both stages the pilot plant was evaluated during solar hours, one day of operation comprised about 7 hours. Normally the experiments were started when the solar filed was delivering a minimum temperature, so the feed was heated up gradually. The modules start to distil, although depending greatly on hot inlet temperature, when a difference of 20 °C in temperature between hot and cold inlet is achieved, and that is when measurements of conductivity and production started.

Following the procedure recommended as a result from IEA Task 33/IV, each potential application for solar process heat systems should initially be analysed to identify the potential for technological optimization of the production process and it’s unit operations, including the potential for heat recovery [2]. Such analysis helps to avoid over-dimensioning of the solar system, and to identify the appropriate temperature level for the integration of solar heat into the process. Since collector efficiencies are strongly temperature dependent, this information is important for the selection of appropriate solar technology and operating temperature of the system. Other important factors are the daily, weekly and annual demand profiles. These, together with the related solar resource data are needed to determine heat storage requirements and the potential solar share. In any case, the design and integration of the solar system needs to take into account that the production has the absolute priority, and the processes must not be impaired by changes in insolation or any other influences from the solar system. On the other hand, it should be endeavoured to utilize as much as possible all energy collected by the solar field.

Since the purpose of this project is the demonstration of direct steam generation in parabolic trough collectors, the solar technology is already pre-determined. Under these conditions, there are three principal options for the integration of the solar steam:

• Solar augmentation of the drying process

• Direct solar steam supply to individual consumers in the new production line

• Solar steam integration into the existing distribution

The effects of an incorrect placement of trough axis, in particular considering the North-South positioning, have been discussed in the previous sections. Referring to the solar trough with parabolic mirror and cylindrical absorber, this section proposes a correction procedure to recuperate the lost light.

The analysis presented in this paper has evidenced that the errors in trough axis positioning generate significant losses of collected energy. Moreover the quantity of missing energy always depends on the sun’s altitude over the horizon. The amount of lost light is graphically visualised in Figures 9-12, for N-S misalignment errors up to 15°.

The solution proposed to recover the lost light consists in using the rotation of the tracking system to compensate N-S misalignment errors. The methodology is completely empirical and its application starts simulating the situations under study, with the different N-S misalignments.

Then, for each case, a rotation angle is applied and the lost light is minimised.

This additional rotation angle is in the direction corresponding to the sun tracking for the N-S positioning. The rotation axis of this compensation is the X axis of Fig. 1, representing the horizontal axis of solar trough. The angular correction corresponds to the daily tracking of the sun position. The values of correction angle are experimentally determined maximising the light received by the absorber.

The results of the application of angular correction are reported in Table 2 considering an error of N-S axis misalignment P=10°. The configuration examined in this study includes a linear parabolic mirror of focal length f=800mm. The absorber is a metal pipe of diameter d=50mm, enclosed into a glass tube of diameter D=60mm and T=3mm.

The examined parameter is the light received by the absorber, expressed in percentage with respect to the impinging light. The reference parameter, in Column 2, is represented by the values obtained without N-S misalignment and without angular correction. These quantities should be reached by the values in Column 4, calculated for p=10° and introducing the angular correction. The empirically determined angle corresponding to each correction is reported in Column 3. It has been calculated for every value of sun’s altitude, indicated in Column 1. But probably the most important quantity is the percentage of recovered light in Column 5. It is obtained as ratio between the values in Column 4 and the reference values in Column 2.

|

Table 2 — Recovering procedure applied for N-S axis misalignment p=10°.

|

A misalignment P=10° in N-S positioning introduces considerable losses that strongly depend on sun’s altitude. The application of a correction angle, using the rotation of the daily sun tracking, recuperates most of missed energy.

It has been verified that this recovering procedure can be successfully applied to the solar parabolic trough under study, considering N-S misalignment angles up to 15°. Over 95% of the lost energy can be recovered using this procedure, compensating the North-South misalignment errors.

Instead of considering the different months, all calculations are performed taking as reference the sun’s altitude over the horizon. Consequently the results can either be associated to the daily sun’s excursion, for North-South positioning, or to the different sun’s positions determined by Latitude and time, for East-West placement.

Ray tracing simulations have analysed a solar trough, whose main component is a linear parabolic mirror that concentrates the light over an absorber composed of a metal pipe surrounded by a glass tube. Since solar trough collectors perform sun concentration only in one direction, the sun tracking is realised only around this axis. The trough axis can either be placed parallel to the North — South direction or parallel to the East-West direction. In N-S positioning the tracking system follows the sun in its excursion during the day. In E-W placement the tracking system follows the sun’s altitude variations during the year.

Referring to the N-S positioning, we have preliminarily discussed the effect of sun’s inclination over the one-axis tracking collector. Considering the Latitude of Firenze (Italy) 43.75° N, the sun’s altitude is maximum (a=69°) in June and minimum (a=23°) in December. The simulations have evidences two main causes of energetic losses: on the light received by the collector aperture (IIN) and on the light received by the absorber (IABS). The amount of received light, normalised to the incoming light, results IIN=37% and IABS=16% for a=23° and it improves to IIN=40% and IABS=20% by introducing a mirror at a trough extreme; while for a=69° we obtain IIN=89% and IABS=72% (with lateral mirror IIN=90% and IABS=74%).

The successive study refers to the incorrect placement of trough axis with respect to N-S direction, taking into account misalignment angles up to 15°. The analyses investigate the interactions between collected light, N-S positioning error and sun’s altitude for different configurations of solar trough. For a parabolic mirror with f=800mm and absorber diameter d=50mm, the collection efficiency is strongly affected by errors in N-S axis positioning (parameterised by the misalignment angle P). If a=69° (June in Florence) the collection efficiency remains around 80% up to P=3°, then it decreases to 56% for p=4°. When a=60° (August) it maintains high values (>74%) for P<2°; then it drops to 23% for P=3°. Finally if a=23° (December) it immediately reduces from 43% (P=0°) to 2% (P=1°).

It can be concluded that the energy loss is considerable and it significantly depends on sun’s altitude a. In order to recover the missed light an empirical correction procedure is proposed and it is applied to the solar trough with parabolic profile and cylindrical absorber. For this configuration most of lost energy can be recovered for p <15°. With N-S axis misalignment P=10° the procedure recuperates 98% of lost light for a=20° and 99-100% for higher values of sun’s altitude. Therefore by using the daily tracking system it is possible to compensate the N-S misalignment errors to recover the missing light.

The research has been developed in the framework of the S. A.L. T.O. project. S. A.L. T.O. (Solar assisted cooling Toscana) is a research integrated project POR Ob. 3 Toscana 2000/2006 Misura D4, partially financed by the REGIONE TOSCANA-settore Promozione e sostegno della Ricerca (Tuscany Region). Thanks are due to the industrial partners FAIT group and CEVIT for their support to our activities in developing Solar Cooling Systems.

[1] C. Ciamberlini, F. Francini, G. Longobardi, M. Piattelli, P. Sansoni Solar system for the exploitation of the whole collected energy Optics and Laser in Engineering 39/2, 233-246 (2003).

[2] F. Francini, D. Fontani, D. Jafrancesco, L. Mercatelli, P. Sansoni Solar internal lighting using optical collectors and fibres, 6338-22, Proceedings of SPIE Vol. #6338, Optics & Photonics SPIE Conference San Diego — USA 13-17 Aug. 2006.

[3] F. Francini, D. Fontani, D. Jafrancesco, L. Mercatelli, P. Sansoni Optical control of sunlight concentrators, 6339-08, Proceeding of SPIE Vol. #6339, Optics & Photonics SPIE Conference San Diego — USA 13-17 Aug. 2006.

[4] F. Francini, D. Fontani, D. Jafrancesco, L. Mercatelli, P. Sansoni Designing solar collectors and optical fibers for daylighting. A novel system exploits solar energy by collecting and channeling sunlight to illuminate interior spaces — Illumination & Displays — Science and Technology: SPIE Newsroom DOI: 10.1117/2.1200612.0487 (2006).

[5] D. Fontani, F. Francini, D. Jafrancesco, G. Longobardi, P. Sansoni Optical design and development of fibre coupled compact solar collectors Lighting Research & Technology 39, 1, 17-30 (2007).

[6] D. Fontani, F. Francini, P. Sansoni Optical characterisation of solar collectors Optics and Laser in Engineering 45, 351-359 (2007).

[7] P. Sansoni, D. Fontani, F. Francini, L. Mercatelli, D. Jafrancesco Optics for concentration on PV cells T3-3.2-08, ISES Solar World Congress 2007, Beijing — China, 18-21 Sept. 2007.

[8] D. Fontani, P. Sansoni, F. Francini, L. Mercatelli, D. Jafrancesco A pinhole camera to track the sun position t5.1.O12, ISES Solar World Congress 2007, Beijing — China, 18-21 Sept. 2007

The fixed position of the mirror arrays in the heliostat field is a limiting factor for the optical performance. Each single mirror has the same characteristics as a classical heliostat. Because of the close spacing, the main problem of the MMA is shading.

To evaluate the characteristics of a MMA and compare its performance to that of a conventional (reference) heliostat of the same size, its performance was evaluated in a raytracing model. The instantaneous reflection efficiency and the annual reflection efficiency are defined as

DNIi and DNIa stand for the instantaneous and annual direct normal insolation respectively. “Pre — flected” and “Ereflected” are respectively the power and energy reflected by the heliostat towards the receiver. Ah is the frontal area of the MMA heliostat box and the mirror area of the conventional helio — stat.

Further testing is to be carried out, investigating wider ranges of temperatures and operating conditions. New heat exchanger relationships will be derived to better predict the effectiveness values, which will bring the model in to better agreement with the actual results. With the model

refined, full year simulations in TRNSYS will be carried out to determine seasonal solar fraction values for the ISAHP system.

The experimental results matched well with the simulated results for the compressor power input, but the simulation over predicted the performance on the system. The compressor power input ranged from 484 — 635 W, and the COP of the system ranged from 2.4 — 3.2 over the duration of the test. The computer model predicted the dynamic operation of the system well, except for a 12% overestimation of performance due to the model’s effectiveness relationships. New seasonal solar fraction values and life cycle cost numbers will be calculated once the full year simulations are completed in TRNSYS.

Support for this work was provided by the Solar Buildings Research Network of Canada, the Ontario Graduate Scholarship Program, and the Natural Science and Engineering Research Council of Canada.

[1] NRCan, (2006). Energy Use Data Handbook, Natural Resources Canada.

[2] C. Aguilar, D. J. White, D. L. Ryan, (2005). Domestic Water Heating and Water Heater Energy Consumption in Canada, Canadian Building Energy End-Use Data and Analysis Centre

[3] G. A. Freeman, (1997). Indirect Solar-Assisted Heat Pumps for Application in the Canadian Environment, Masters Thesis, Department of Mechanical Engineering, Queen’s University.

[4] G. A. Freeman, S. J. Harrison, (1997). Solar Assisted Heat Pump Hot Water Heaters for the Canadian Environment, Proceedings of 1997 SESCI Conference, Vancouver, BC.

[5] K. Chaturvedi, J. Y. Shen, (1982). Analysis of Two-Phase Flow Solar Collectors with Application to Heat Pumps, Journal of Solar Energy Engineering, Vol. 104, 358

[6] Morrison, G. L, (1994). Simulation of Packaged Solar Heat-Pump Water Heaters, Solar Energy, Vol. 53, 249

[7] P. Sporn, E. R. Ambrose, (1955). The Heat Pump and Solar Energy, Proceedings of the World Symposium on Applied Solar Energy, Phoenix, Ariz.

[8] Chaturvedi, K., Abazeri, M, (1987). Transient Simulation of a Capacity-Modulated Direct-Expansion, Solar-Assisted Heat Pump, Journal of Solar Energy, Vol. 39, 441

[9] B. J. Huang, J. P. Chyng, (1998). Integral-Type Solar-Assisted Heat Pump Water Heater, Journal of Renewable Energy, Vol. 16, 731

[10] B. J. Huang, C. P. Lee, (2003). Long-Term Performance of Solar-Assisted Heat Pump Water Heater, Journal of Renewable Energy, Vol. 29, 633

[11] J. M. Purdy, S. J. Harrison, P.H. Oosthuizen, (1998). Compact Heat Exchanger Evaluation for Natural Convection Applications, Proceedings of the 11th IHTC Heat Transfer 1998, Korea, Vol. 6, 305

[12] University of Wisconsin, Solar Energy Laboratory, (2006). TRNSYS: A Transient Simulation Program, Madison

[13] A. Bridgeman, S. J. Harrison, (2008). Preliminary Experimental Evaluation of Indirect Solar Assisted Heat Pump Systems, Proceedings for The 3rd Annual Canadian Solar Buildings Conference, Fredericton, NB

[14] A. H. Fanney, S. A. Klein, (1988). Thermal Performance Comparisons for Solar Hot Water Systems Subjected to Various Collector Array Flow Rates, Proceedings of Intersol 85, Montreal, QC.

As the longitude has a minor influence on heliostat annual average efficiency, the influence of latitude is only discussed in this paper. Fig.3 is the scattergram of heliostat annual average efficiency in the field on 25 degrees north considering the influence of tower but neglecting the interaction of heliostats. From Fig.3, we can know that the location which lies due north of the tower with a distance of 1.48Ht is maximum efficiency point. Efficiency get lower with gradually outward from this spot, furthermore the efficiency is rapidly declined when the distance is less than 0.4Ht. The distributing regulation of heliostat efficiency in the field lying on other latitude is

about same. Thus, it can be defined that the line connecting the maximum efficiency point in the field and the center of receiver aperture is the normal of the center of receiver aperture. And the angle between this line and horizon is receiver depression angle aR.

The relationship between receiver depression angle aR and latitude L is shown as Fig.4, and the relationship curve can be numerically expressed as the follows by fitting. aR = -0.0027L2 + 1.0452L + 31.4456 ( 8 )

|

Fig.3 Scattergram of heliostat annual average efficiency in the field on 25 degrees north |

|

Ffecei ver Cfepressi on Angl e Fig.4 Relationship between receiver depression angle and latitude |

A series a 39 steady-state performance points is achieved, by modifying the working conditions as indicated in the table below:

|

Working condition |

Minimum value |

Maximum value |

|

First hot air source mean temperature |

53.4 °C |

86.4 °C |

|

Second hot air source mean temperature |

101 °C |

163.2 °C |

|

Air flow rate |

0.071 kg/s |

0.90 kg/s |

|

Refrigerant flow rate |

45 g/s |

86 g/s |

|

Condenser water flow rate |

0.13 l/s |

0.70 l/s |

|

Condenser mean water temperature |

13.2 °C |

15 °C |

|

Expander rotation speed |

1771 rpm |

2660 rpm |

/

Three performance indicators are taken into account: the expander shaft power, the expander isentropic effectiveness, and the cycle efficiency.

The expander isentropic effectiveness is defined by: & =

Mir * (hr, su, exp hr, ex, exp, s)

W — W

And the cycle efficiency by: T]cycie = shexp —

Qevap

A shaft power ranging from 0.38 to 1.82 kW is obtained, corresponding to a mechanical isentropic effectiveness ranging from 43 to 68% and a maximum cycle efficiency of 7.4%. The pressure ratio over the expander varied from 2.7 to 5.4.

The starting point for the design of the concentrator geometry was the concept of the Fixed Mirror Solar Concentrator (FMSC) that is illustrated in Figure 1. Although the first development was

|

already carried out during the 70’s by the General Atomic Company [3], at present no commercially available collectors use this concept.

A complete analysis of the reflector optics, based on the forward ray tracing method, was carried out [4]. The main parameters taken into account in that study were the geometric concentration factor and the D/W ratio (see Fig. 1). On the one hand, this study together with the results already available on the literature [5, 6, 7] show that working temperatures of 200°C and higher could be easily obtained and that the radiation distribution in the focus is quite uniform (compared to other geometries). On the other hand, the concentration factor depends on the number of steps (or flat mirrors), which complicates manufacturing with the required precision, and the sealing of the mirror edges. Another problem of this geometry was that for low transversal sun angles the interference of the reflected rays with the adjacent mirrors produces high energy losses.

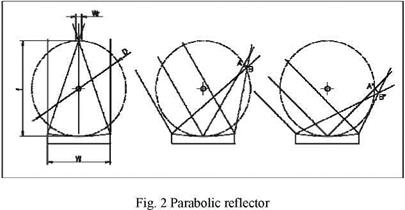

Therefore it was decided to investigate the possibility of reducing the number of the required steps by using curved mirrors. Although it is well known that a parabolic reflector only produces a point focus for normal incidence, it can be shown from simple geometric considerations, that its degraded focus describes a circular path similar to the FMSC [8]. Thus the parabolic curve was chosen as the main candidate for the curvature of each of the mirrors.

|

From the same study [8] it was clear that for low geometrical concentration factors the best solution consisted in replacing the stepped geometry by only one parabolic reflector (Figure 2). Therefore a more detailed optical analysis of this geometry was performed [9].

The optical studies were complemented with a simple thermal analysis at 120°C [8]. The figure 3 shows the annual averaged efficiency estimations, referred to the global radiation incident on the reflector aperture, using available Mallorca’s radiation data and the TRNSYS climate processor.

|

As can be seen, the best annual averaged efficiency is obtained for the single mirror arrangement and a concentration factor between 10 and 12. The figure 3 was obtained for a D/W ratio of 1.5. The precise value of the optimal concentration ratios and the estimated efficiencies depend on the D/W ratio assumed, but in all cases of practical interest the best results were obtained for the single mirror reflector.

|

Regarding to the D/W ratio, for ideal reflectors it is clear that the efficiency increases with increasing D/W values. Nevertheless, in practical implementations, its value is limited to values below 2 due to both the dispersion produced by the mirrors and the precision of the tracking mechanism. In the first prototype the chosen value was 1.5.

The figure 4 shows the estimated incidence angle modifiers (IAM) for the chosen geometry, taking also into account the finite length of the collector and the interference between adjacent receivers.